The Versatility and Applications of Punched Copper Sheets

Punched copper sheets are a remarkable material widely used in various industries due to their unique properties and aesthetic appeal. Copper, as a metal, is known for its excellent conductivity, corrosion resistance, and malleability. When combined with the process of punching, these sheets offer enhanced functionality, making them suitable for a multitude of applications.

Understanding Punched Copper Sheets

Punched copper sheets are produced by taking a flat copper sheet and using a die to create holes or patterns. This process not only reduces the weight of the sheet but also increases its surface area, which can be beneficial in various applications. The size, shape, and arrangement of the punched holes can be tailored to meet specific needs, allowing for customized designs. This versatility is one of the primary reasons why punched copper sheets are favored in various domains.

Applications in Architecture and Interior Design

One of the most striking uses of punched copper sheets is in architectural design. They are often used as decorative elements in facades, ceilings, and wall coverings, adding a sophisticated and modern look to buildings. The play of light through the holes creates dynamic visuals that change throughout the day, enhancing the aesthetic appeal of any structure. Additionally, their corrosion resistance makes them suitable for both indoor and outdoor applications, ensuring durability and longevity.

In interior design, punched copper sheets can be found in features such as room dividers, chandeliers, and wall art. The unique patterns can be manipulated to create stunning visuals, contributing to the overall ambiance of a space. Designers appreciate the flexibility of these sheets, as they can be easily cut, shaped, and installed, allowing for creative freedom.

Utility in Industrial Applications

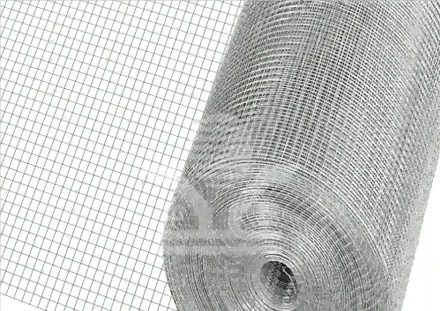

punched copper sheet

Beyond aesthetic applications, punched copper sheets are incredibly functional in industrial settings. Their enhanced surface area allows for better heat dissipation, making them ideal for components in electronic devices, heat exchangers, and various mechanical parts. The lightweight nature of punched sheets contributes to the overall efficiency of machinery, reducing energy consumption without compromising strength.

Moreover, punched copper sheets are often used in filtration systems, providing structural support while allowing fluids or gases to pass through the perforations. Their resistance to corrosion and ability to withstand varying environmental conditions make them suitable for a range of industrial applications, from manufacturing to HVAC systems.

Artistic Uses and Craftsmanship

In the realm of art and craftsmanship, punched copper sheets provide artisans and crafters with endless possibilities. Artists utilize these sheets to create intricate designs, sculptures, and custom installations. The warm, natural color of copper adds a unique character to artworks, and the ability to manipulate the material easily allows for innovative creations.

Craftsmen often experiment with punching techniques to produce unique patterns, enhancing the decorative quality of their pieces. Workshops and classes centered around working with punched copper sheets are becoming increasingly popular, empowering individuals to explore their creativity while mastering various metalworking skills.

Conclusion

In conclusion, punched copper sheets exemplify the fusion of functionality and beauty. Whether in architectural applications, industrial settings, or artistic endeavors, these sheets provide a versatile solution that meets diverse needs. As technology advances and industries continue to innovate, the potential uses of punched copper sheets will likely expand, solidifying their place as a valuable material in both contemporary and traditional contexts. With their distinctive properties and wide-ranging applications, punched copper sheets are truly a testament to the enduring appeal of copper in modern craftsmanship and industry.

-

Using Round Hole Mesh for Concrete Formwork Protection

NewsJul.09,2025

-

The Recyclability of Stainless Steel Mesh in a Circular Economy

NewsJul.09,2025

-

Steel Gratings in Green Construction Projects

NewsJul.09,2025

-

How Engineers Design Steel Structure Platforms for Maximum Safety

NewsJul.09,2025

-

Cable Mesh Railing for Rooftop Gardens and Terraces

NewsJul.09,2025

-

Aluminum Diamond Mesh: A Comprehensive Overview

NewsJul.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.