Understanding Metal Sheets with Holes Applications and Benefits

Metal sheets with holes are a fundamental component in various industries, serving a multitude of purposes. They consist of flat sheets of metal, such as steel, aluminum, or brass, that have been perforated or laser-cut to create holes of specified sizes and patterns. The versatility and functionality of these sheets make them indispensable in fields ranging from construction to electronics.

One of the primary benefits of metal sheets with holes is their lightweight yet durable nature. Manufacturers often use materials like aluminum for applications requiring strength without excessive weight. Perforated metal sheets are widely used in the automotive industry for both structural components and decorative elements. They can be found in car grilles, decorative panels, and even sound-dampening applications. The perforations allow for air and light passage, which can be crucial for exhaust systems and ventilation.

Understanding Metal Sheets with Holes Applications and Benefits

Another significant application is in the manufacturing of filters. Metal sheets with holes can be designed to various specifications, making them ideal for use in air, water, and liquid filtration systems. The size and spacing of the holes can be meticulously adjusted to control the flow of liquids and gases, ensuring optimum filtration efficiency. These sheets provide a balance between structural integrity and filtration capacity, making them essential in industries like pharmaceuticals, food processing, and environmental control.

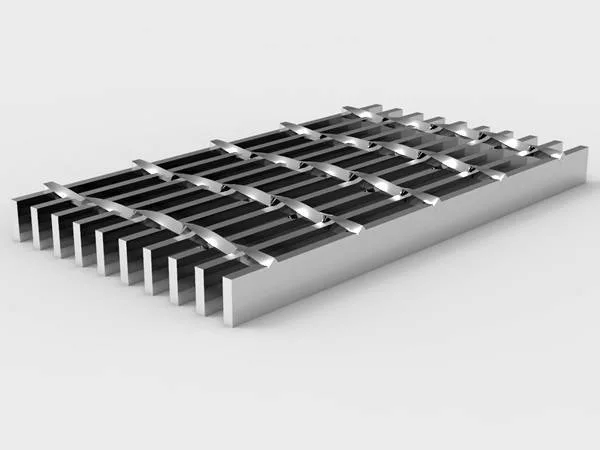

metal sheet with holes

Moreover, the processing of metal sheets with holes allows for increased versatility. They can be finished in a variety of ways, such as powder coating, anodizing, or galvanizing, to enhance corrosion resistance and aesthetic appeal. Advanced techniques, such as laser cutting and CNC machining, enable manufacturers to create intricate designs and custom sizes, catering to the specific needs of their clients. This flexibility opens up endless possibilities for innovation in product design and production.

Furthermore, the use of metal sheets with holes supports sustainability practices. They are often made from recyclable materials, and the manufacturing process can be optimized to minimize waste. By integrating these sheets into products, companies can reduce their overall material consumption and leverage the benefits of lightweight construction, which can lead to energy savings in transportation and installation.

In the realm of electronics, perforated metal sheets find their use in shielding and cases for sensitive equipment. The perforations allow for ventilation while protecting internal components from electromagnetic interference (EMI). By ensuring optimal airflow, these sheets help maintain the efficiency and longevity of electronic devices.

In conclusion, metal sheets with holes are versatile materials that serve an array of applications across multiple industries. Their unique properties, including lightweight durability, aesthetic appeal, and customizable features, make them invaluable in modern manufacturing and design. As technology progresses, the possibilities for using these sheets continue to expand, promising innovative solutions for the challenges faced in architecture, automotive design, environmental management, and beyond. Whether enhancing functionality or improving aesthetics, the impact of metal sheets with holes is profound, shaping the way we build and interact with our environment.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.