In the realm of construction and industrial applications, expanded metal has emerged as a versatile and reliable material with a wide range of uses. This unique mesh-like product is created by slitting and stretching regular metal sheets, resulting in a pattern of diamond-shaped openings. In this blog post from Mcneil Instrument, we will delve into the world of expanded metal, exploring its manufacturing process, key characteristics, and diverse applications across various industries.

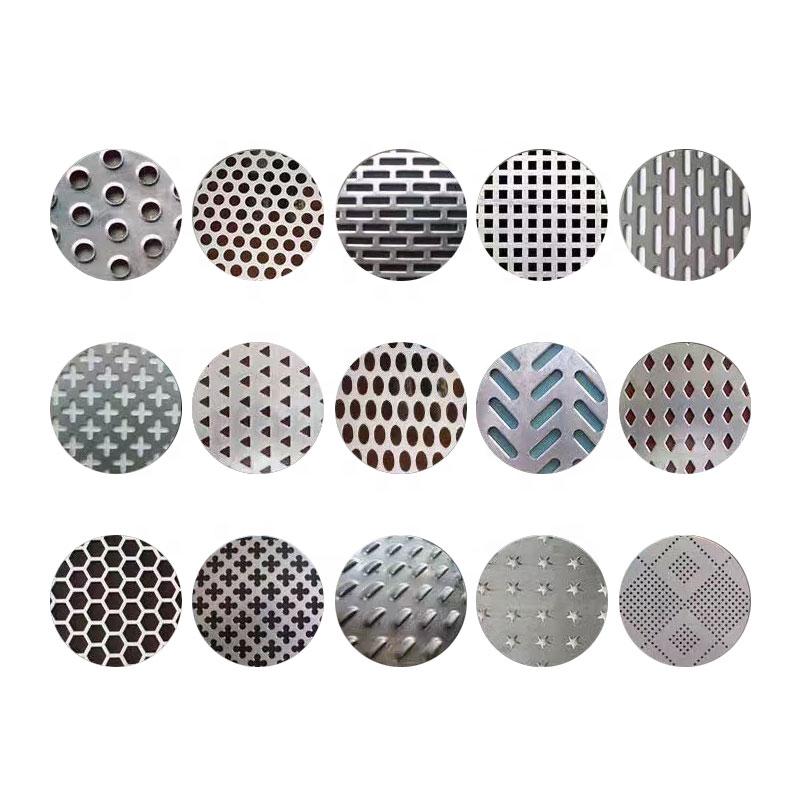

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

Understanding the Manufacturing Process

Expanded metal is manufactured through a meticulous process that involves cutting and stretching metal sheets, transforming them into a mesh structure. The primary metals used for this purpose include aluminum, stainless steel, carbon steel, and other alloys. The process begins with flat metal sheets that are subjected to slitting, creating uniform slits without completely separating the material. Following this, the sheets are stretched, expanding the slits and forming the characteristic diamond-shaped openings.

Key Characteristics of Expanded Metal

Versatility and Flexibility: One of the standout features of expanded metal is its versatility. The ability to choose from various metals and configurations makes it suitable for a broad spectrum of applications. Expanded metal can be customized to meet specific requirements, providing flexibility in terms of size, shape, and thickness.

Strength and Durability: Despite its open and airy appearance, expanded metal is surprisingly strong and durable. The stretching process enhances the structural integrity of the material, making it resistant to impact, wear, and corrosion. This robustness makes expanded metal an ideal choice for applications where strength and longevity are paramount.

Weight Reduction: Compared to solid sheets of metal, expanded metal offers the advantage of reduced weight without compromising strength. This makes it a preferred material in applications where weight is a critical factor, such as architectural elements, automotive components, and lightweight structures.

Types of Expanded Metal

Expanded metal comes in various types, each designed to cater to specific applications and requirements. The selection of a particular type depends on factors such as material, pattern, opening size, and thickness. Here are some common types of expanded metal:

Standard Expanded Metal

- This is the most basic and commonly used type of expanded metal.

- It is produced by simultaneously slitting and stretching a single sheet of metal, creating diamond-shaped openings.

- Standard expanded metal is available in various materials, including aluminum, stainless steel, and carbon steel.

Flattened Expanded Metal

- The process of flattening involves cold-rolling the standard expanded metal to reduce its thickness.

- Flattened expanded metal has a smoother surface and offers a lower profile than standard expanded metal.

- It is often preferred for architectural and decorative applications.

Raised Expanded Metal

- In contrast to flattened expanded metal, raised expanded metal retains its original thickness.

- This type of expanded metal has a slightly raised profile, providing enhanced strength and rigidity.

- Raised expanded metal is suitable for applications where additional strength is a priority.

Micro Expanded Metal:

- Micro-expanded metal features smaller diamond-shaped openings compared to standard expanded metal.

- It is often used in applications requiring finer filtration or where a more intricate pattern is desired.

- Commonly employed in industries such as electronics and pharmaceuticals.

Hexagonal Expanded Metal

- Hexagonal expanded metal, as the name suggests, features hexagon-shaped openings.

- This type of expanded metal provides a unique aesthetic appeal and is used in decorative and architectural applications.

- It may also offer improved ventilation and visibility in certain applications.

Architectural Mesh

- Architectural mesh is a specialized type of expanded metal designed for decorative purposes.

- It is available in various patterns and materials, allowing for creative and aesthetically pleasing designs in architectural projects.

- Architectural mesh is often used in building facades, interior design, and artistic installations.

Aluminum Expanded Metal

- Expanded metal made from aluminum is lightweight, corrosion-resistant, and ideal for applications where weight reduction is critical.

- It finds use in architectural elements, automotive components, and lightweight structures.

- The material’s non-magnetic properties make it suitable for certain electronic applications.

Stainless Steel Expanded Metal

- Stainless steel expanded metal offers excellent corrosion resistance, durability, and strength.

- It is commonly used in industrial settings, food processing equipment, and outdoor applications where exposure to harsh environments is a concern.

- Stainless steel expanded metal is available in various grades for specific corrosion resistance requirements.

Carbon Steel Expanded Metal

- Carbon steel expanded metal is known for its strength and cost-effectiveness.

- It is widely used in industrial applications, construction, and manufacturing.

- Carbon steel expanded metal may be coated or galvanized to enhance corrosion resistance.

Copper Expanded Metal:

- Copper expanded metal provides a unique aesthetic appeal with its distinctive color.

- It is corrosion-resistant and often used in decorative applications, architectural projects, and artistic installations.

Applications Across Industries

Construction Industry: In the construction sector, expanded metal finds widespread use in various applications. It is commonly employed as reinforcement in concrete structures, providing additional strength to walls, floors, and ceilings. Additionally, expanded metal is used for architectural purposes, creating decorative facades, railings, and sunshades.

Industrial Manufacturing: Expanded metal’s adaptability and durability make it a staple in industrial manufacturing. It is often utilized as machinery guards, safety barriers, and conveyor belt systems. The material’s open design allows for optimal ventilation and visibility, ensuring a safe and efficient working environment.

Automotive Sector: In the automotive industry, expanded metal serves multiple functions. It is used for manufacturing components like grilles, radiator guards, and air intake screens. The material’s lightweight nature contributes to fuel efficiency while maintaining structural integrity.

Security and Fencing: The security sector benefits significantly from the application of expanded metal in the fabrication of fences, gates, and security screens. The material’s strength and design discourage unauthorized access while providing clear visibility.

HVAC and Ventilation: Expanded metal’s open structure facilitates optimal air circulation, making it an ideal choice for HVAC systems and ventilation applications. Air filters, grilles, and diffusers are commonly manufactured using expanded metal due to its balance of airflow and filtration efficiency.

Sustainability and Environmental Considerations: As the world continues to prioritize sustainable practices, expanded metal stands out as an eco-friendly option. Its durability and recallability contribute to reduced waste, making it a responsible choice for environmentally conscious projects. The material’s energy-efficient production process further aligns with sustainability goals.

Maintenance and Care: While expanded metal is known for its durability, proper maintenance is essential to ensure its longevity. Regular cleaning and inspections can help prevent corrosion and address any signs of wear. Understanding the specific maintenance requirements for different metals is crucial to maximizing the lifespan of expanded metal components.

Conclusion

Expanded metal has evolved into a versatile and indispensable material across various industries. From its unique manufacturing process to its applications in construction, manufacturing, automotive, security, and HVAC, expanded metal continues to prove its worth. As industries evolve and embrace sustainability, expanded metal’s durability and recallability position it as a material of choice for the future. Whether used for structural reinforcement, decorative elements, or security applications, expanded metal stands as a testament to the innovation and adaptability of materials in the modern world.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.