Expanded metal mesh sheet is fabricated with a regular pattern of diamond-shaped openings. These openings reduce the weight and cost of the sheet and provide ventilation, making it a versatile solution for many applications. The most common metals used for expanded metal sheet include steel, stainless steel, and aluminum, although it is also made from titanium and copper.

How is Expanded Metal Sheet Manufactured?

Expanded sheet is made from a single sheet of metal slit by a row of knives mounted on an industrial die-cutting machine. The blades move back and forth in a uniform pattern, slicing the sheet in alternating cuts while the sheet moves through the machine.

As the knives cut, they simultaneously push down on the newly cut sections, stretching them apart into “ribbons.” The ribbons remain attached to the uncut sections, which become the corners of open diamond shapes in an expanded mesh sheet. The knives' size, shape, positioning, and thickness of the metal sheet can be changed to create openings of different dimensions for various applications.

Expanded Metal Sheet Options

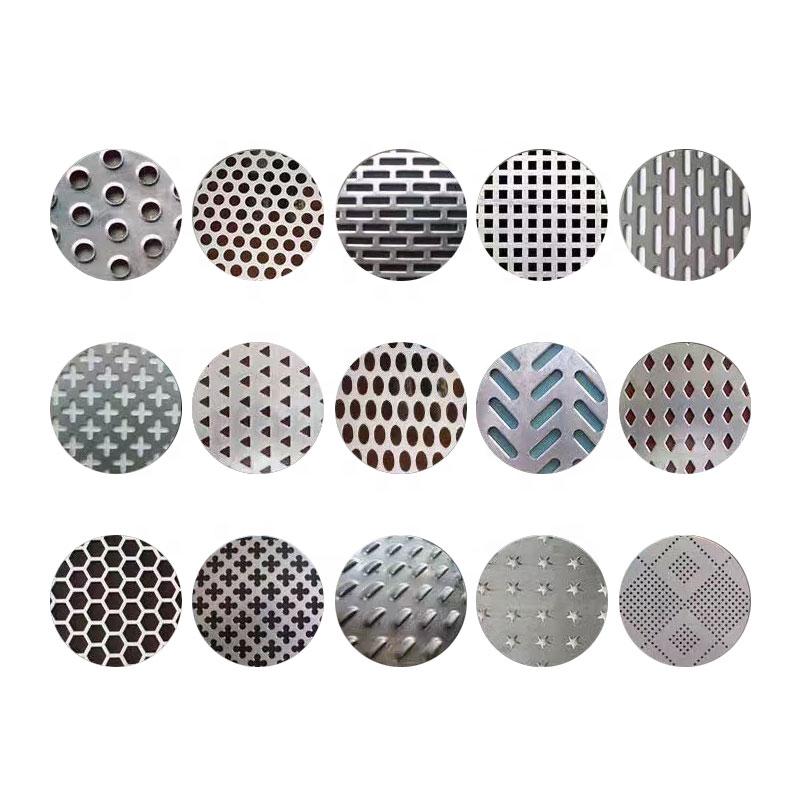

Expanded metal mesh sheet is available in several unique options to provide the features your project requires; it’s available in several individual profiles, including:

Standard Expanded Sheet

Raised expanded metal sheet is a finished product when it comes off the press after being cut and expanded. Raised expanded metal sheet features alternating ridges formed by overlapping metal strips that create a diamond pattern. The expanded metal sheet’s diamond pattern helps to permit air circulation. Standard metal sheets can be produced in various sizes and weights, which can be used when making lockers, warehouse fencing, and machinery safety doors.

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

Flattened Expanded Sheet

Flattened expanded sheet is about 5% lighter than standard expanded sheet and is cold rolled, leaving a flat, smooth surface. The cold rolling process flattens the metal and helps to make it flatter, thinner, and longer. Flattened expanded sheet’s slip-resistant coating makes it ideal for construction walkways and stairways. It can also be used for fencing, décor, and ventilation applications.

Expanded Metal Grating

Expanded metal grating has no joints or welds and is heavier than standard expanded metal mesh products, as each sheet is a single piece of sturdy steel. Expanded metal grating is ideal for catwalk, stair, and platform applications, providing an outstanding strength-to-weight ratio. Expanded metal grating is one of the most solid and cost-effective expanded metal sheet products available.

Benefits of Expanded Metal Sheet

Expanded sheet metal is a versatile and economical product that is durable, easy to work with, and provides low wind resistance. It offers one-piece construction that won’t unravel under normal circumstances and will hold its shape for many years. The strands and bonds of the diamond-shaped trusses add strength and rigidity. Additional advantages include:

- High strength

- Versatility

- Cost-effective

- Corrosion resistant

- Durable

- Conductive

Expanded Metal Mesh Applications

Steel expanded metal sheet is commonly used for the following applications:

- Machine guards

- Catwalks, platforms, and stair treads

- Grating/flooring

- Stair and balcony railing mesh

- Window security

- Vents

- Conveyors

- Shelves

- And much more

Expanded Metal Material Options

Expanded sheet is available in standard (raised) or flattened diamond patterns, in various gauges, opening sizes, and sheet sizes. Materials we stock include:

- Expanded steel sheet

- Expanded aluminum sheet

- Expanded stainless steel sheet

Expanded Aluminum sheet comes in two sizes which are both flattened. IMS stocks several more sizes in steel expanded sheet metal; all flattened except for our 3/4" pattern, which is raised.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.