At HuanJi, we understand the importance of making informed decisions when it comes to selecting materials for your projects. Galvanized expanded metal is a popular choice in various industries due to its unique characteristics and versatility. In this comprehensive article, we will delve into the pros and cons of galvanized expanded metal, providing you with valuable insights to help you make the best choice for your specific needs.

Pros of Galvanized Expanded Metal

1. Durability and Strength

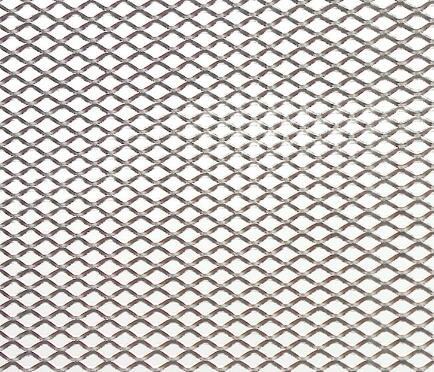

Galvanized expanded metal is renowned for its exceptional durability and strength. The process of galvanization involves applying a protective zinc coating to the metal, making it highly resistant to corrosion, rust, and weathering. This durability ensures that galvanized expanded metal can withstand harsh environmental conditions, making it ideal for both indoor and outdoor applications.

2. Cost-Effective Solution

One of the major advantages of galvanized expanded metal is its cost-effectiveness. Compared to other materials with similar properties, galvanized expanded metal offers a cost-efficient solution without compromising on quality. Its long lifespan, low maintenance requirements, and resistance to wear and tear contribute to significant cost savings over time.

3. Versatility

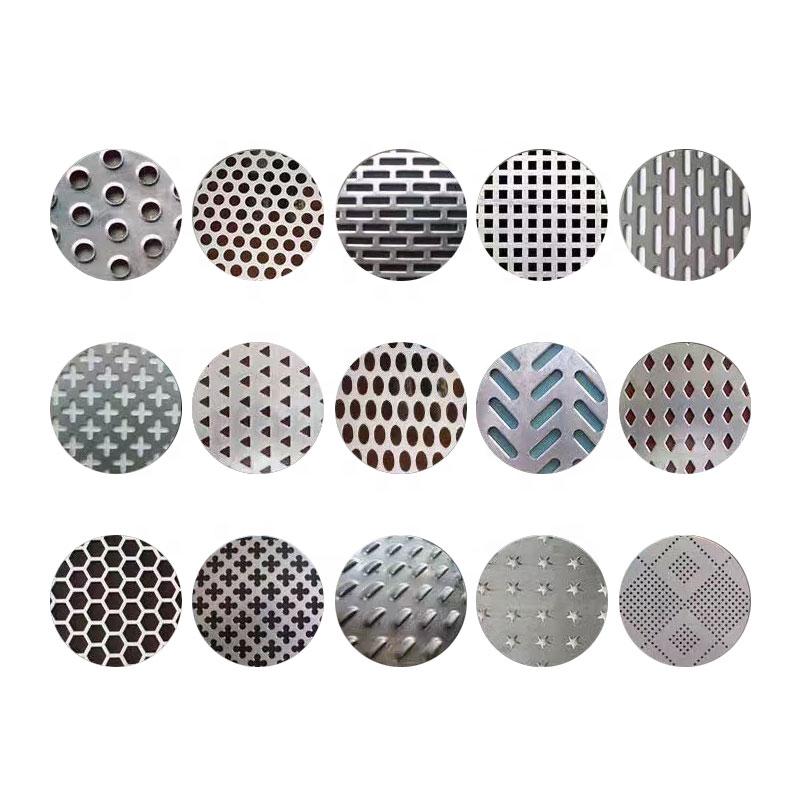

Galvanized expanded metal is highly versatile and finds application in a wide range of industries. It can be used for security fencing, architectural grilles, walkways, machine guards, ventilation panels, and much more. Its flexibility allows for customization, enabling it to adapt to various design requirements and specifications.

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

4. Excellent Ventilation and Visibility

Due to its unique design with diamond-shaped openings, galvanized expanded metal offers excellent ventilation and visibility. This feature makes it an ideal choice for applications that require airflow, light penetration, or visibility while still maintaining security and structural integrity.

5. Easy Installation

Installing galvanized expanded metal is a straightforward process. The material is lightweight, which simplifies handling and reduces installation time and costs. Its flexibility allows it to be easily shaped and cut to fit specific dimensions, ensuring a seamless installation process.

Cons of Galvanized Expanded Metal

1. Susceptibility to Scratching

While galvanized expanded metal boasts impressive durability, it is susceptible to scratching. Sharp objects or abrasive materials can potentially cause scratches on the surface, compromising its protective zinc coating. Regular inspections and maintenance are necessary to identify and address any scratches promptly.

2. Limited Color Options

Galvanized expanded metal typically comes with a silver-gray appearance due to the zinc coating. While this can be suitable for many industrial applications, it may not offer the desired aesthetic appeal for certain projects. However, additional painting or powder coating can be applied to achieve the desired color and enhance its visual appeal.

3. Potential for Sharp Edges

During the expansion process, galvanized expanded metal may develop sharp edges. Although these edges can be filed or deburred, it is important to handle the material with care to prevent any potential injuries. Wearing protective gloves and taking necessary precautions when working with galvanized expanded metal is highly recommended.

4. Limited Size Availability

Another limitation of galvanized expanded metal is the availability of standard sizes. While many sizes are readily available, certain projects may require custom dimensions. In such cases, additional lead time and costs may be incurred to accommodate the specific size requirements.

5. Conductivity

Galvanized expanded metal has inherent electrical conductivity due to its metallic composition. While this characteristic can be advantageous in certain applications, it may pose limitations in situations where electrical insulation is necessary. Proper insulation measures need to be implemented to ensure safety in such scenarios.

Conclusion

Galvanized expanded metal offers a myriad of benefits, making it a popular choice across various industries. Its durability, cost-effectiveness, versatility, excellent ventilation, and easy installation make it an attractive option for numerous applications. However, it is essential to consider the potential drawbacks, such as susceptibility to scratching, limited color options, sharp edges, limited size availability, and electrical conductivity.

By understanding the pros and cons of galvanized expanded metal, you can make an informed decision that aligns with your specific project requirements. At HuanJi, we are committed to providing you with the highest quality materials and expertise to ensure the success of your projects. We are a galvanized expanded metal supplier. If you are interested in our products, please contact us now!

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.