Expanded metal is manufactured from a sheet of metal using a shear-form process.

It’s fed under a set of knives, and slit and simultaneously stretched–not punched–producing a uniform diamond-patterned mesh. Its single-piece composition results in a very high strength-to-weight ratio, unlike other products, such as welded or woven wire. There are no points at which the material can separate. It can be made from aluminum, steel or other metals, and various coatings such as paint, print and powder coating can be applied.

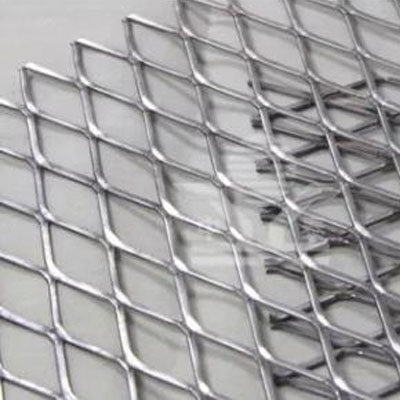

Stainless Steel Plate Material Galvanized Expanded Metal Mesh

There is another advantage for using expanded metal: It is a green product that can earn LEED credits. Since it is slit instead of punched, there is very little to no waste. The typical yield of finished to raw product is three-to-one, and in many cases much greater. It has high amounts of recycled material content, is completely recyclable, and production costs are minimal because no additional components, processes or additives are required. The uses for expanded metal fall into five categories: protection, enclosure, support, filtration and decoration. Examples for construction are featured below.

Safeguarding and Enclosing the Jobsite

Safeguarding job-site workers from accidents is imperative. According to OSHA, in 2015, the leading cause of private sector worker deaths (excluding highway collisions) in the construction industry was falls, such as through a skylight. OSHA mandates that “skylight screens shall be of such construction and mounting that they are capable of withstanding a load of 200 pounds applied perpendicular at any one area of the screen.” In California, 400 pounds is the minimum. When properly implemented, skylight screens using expanded metal can meet rooftop safety requirements. Falls from slips can be reduced by using traction control measures. Expanded metal has inherent anti-slip properties that are useful as scaffolding, walkways and stairs, or where oils, ice or other slick substances pool.

Enclosing the job site and equipment with expanded metal serves as a powerful deterrent against theft and vandalism. Common perimeter fencing can be constructed from chain link; to provide better protection. Since it’s constructed from a solid sheet of metal, it is difficult to cut and the tops can be left with random shears that are sharper than chain link, prohibiting someone from climbing over. Tool cribs, lockers and equipment cages made from expanded metal provide superior protection from theft. Because it has no points that can separate, it will take quite a while for someone to cut through each strand.

For building specs that require additional fortification such as banks, expanded metal can be added to the interior of walls to stop someone from cutting through drywall. When applied to windows and doors as a security screen, it is very effective in prohibiting crimes such as a smash and grab. Its small openings don’t let fingers or cables through, preventing the screen from being forcibly removed.

Support with Expanded Metal

Excellent for stone veneers, masonry, tiles and even ceilings, expanded metal features a raised pattern to allow the keying of plaster for secure adhesion. It is used to support and reinforce areas prone to cracking such as around doors and windows, or where corners meet walls or ceilings. All are available in coils for job-site portability, or in sheets for larger jobs. For landscaping, expanded metal support can be used to form pools, ponds, decking and even intricate shapes for topiaries.

Filtration and Ventilation

A significant advantage for using expanded metal in filters is that it is extremely strong. When used to filter lubricants such as oil or grease for heavy equipment, expanded metal functions as a prefilter by straining large particulates and restricting such contaminants from reaching the filter media. This not only maximizes the filter’s efficiency, but also increases its life cycle.

Keeping HVAC systems running at optimum levels require that filters be changed at regular intervals. Expanded metal is the industry choice for metal backing in pleated filters. Since its introduction in 1975, it replaced the need for welded wire, is cost effective, and provides a uniform media pleat element to deliver consistent performance.

When the application requires the filtration of fuels, vapors or gasses, micro meshes with openings 0.125-inch and smaller are extremely effective. For ventilation, expanded metal has a lower cost over other open area metals. It can be used as ceiling diffuser grilles which offers a greater open area yielding less air restriction. Decorative patterns, finishes and colors can be used to match décor.

Decorating with Expanded Metal

Not limited to a diamond-shaped pattern, expanded metal can be formed into attractive designs to complement existing architectural elements including gutter guards, chimney caps and building façades. Additional uses include outdoor furniture, trellises, fire screens and shades. Paint or powder coat can be applied to maximize longevity.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.