Understanding Dutch Weave Wire Mesh A Versatile Solution for Filtration

Dutch weave wire mesh has emerged as a favored choice in various industries due to its exceptional filtering capabilities and structural integrity. This type of mesh is commonly utilized for separating solid particles from liquids or gases, making it indispensable in sectors such as oil and gas, food processing, pharmaceuticals, and more. In this article, we will explore the characteristics, manufacturing process, applications, and benefits of Dutch weave wire mesh.

Characteristics of Dutch Weave Wire Mesh

Dutch weave wire mesh is characterized by its unique weaving pattern, which consists of alternating layers of fine and coarse wires. The typical structure includes a thicker wire running in one direction and a finer wire interwoven in the perpendicular direction. This design not only provides excellent filtration but also enhances the strength and durability of the mesh. The tight weave enables the mesh to filter out even the smallest particles while preventing the escape of larger contaminants.

The mesh is available in various material options, including stainless steel, brass, and bronze, with stainless steel being the most popular due to its corrosion resistance and longevity. The mesh can also be produced in different wire diameters and mesh sizes, making it suitable for diverse applications based on specific filtration needs.

Manufacturing Process

The manufacturing of Dutch weave wire mesh involves precise engineering and attention to detail. The process begins with selecting high-quality wire materials, which are then cut to the desired lengths. The wires are woven together using advanced machinery that can create various patterns. The unique Dutch weaving technique requires skilled operators who can maintain the correct tension and alignment of the wires to ensure the final product meets strict quality standards.

After weaving, the mesh undergoes finishing processes such as cleaning, annealing, and possibly surface treatments to enhance its performance characteristics. The final product is then tested for its filtration efficacy, structural integrity, and corrosion resistance before being packaged for distribution.

Applications of Dutch Weave Wire Mesh

Dutch weave wire mesh is incredibly versatile and finds usage across a broad range of applications

. Some key areas includedutch weave wire mesh

1. Filtration in Petroleum and Chemical Industries Dutch weave mesh is essential for separating impurities from liquids and gases in oil and gas production, enhancing product quality and compliance with strict environmental regulations.

2. Food and Beverage Processing In the food industry, this mesh is used in processing plants for filtering food products and beverages, ensuring that contaminants are removed while maintaining product integrity.

3. Water Treatment The mesh effectively filters sediments and particulates from water, making it a critical component in water treatment facilities.

4. Pharmaceuticals In pharmaceutical manufacturing, Dutch weave wire mesh is used to maintain product purity and prevent contamination in sensitive processes.

5. Aerospace and Automotive Industries The lightweight and robust nature of this mesh allows for use in applications that require precision and reliability.

Benefits of Dutch Weave Wire Mesh

The advantages of using Dutch weave wire mesh are manifold. First and foremost, its high strength-to-weight ratio makes it an ideal choice for demanding environments. The mesh's precise filtration capabilities ensure efficiency, reducing operational costs associated with product wastage and downtime.

Additionally, the durability of materials like stainless steel means that the mesh will last longer, providing a cost-effective solution over time. The ease of cleaning and maintenance also contributes to its attractiveness to industries that require hygienic conditions.

In conclusion, Dutch weave wire mesh stands out as a critical material across various industries, thanks to its unique structural qualities and superior filtration capabilities. As businesses continue to seek efficient and reliable solutions for their filtration needs, the demand for Dutch weave mesh is likely to grow, further cementing its position as a vital component in modern industrial applications. Its versatility, strength, and performance make it an indispensable tool for achieving quality and safety in diverse environments.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

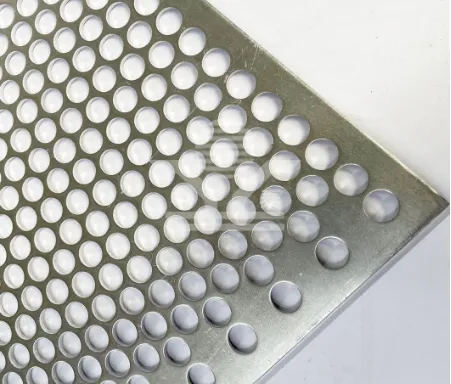

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.