Dutch Weave Wire Mesh A Versatile Solution for Filtration and Separation

Dutch weave wire mesh is a unique type of woven wire mesh that has gained immense popularity across various industries due to its exceptional filtration capabilities and durability. This specialized mesh is characterized by its distinct weave pattern, which consists of a combination of both plain and twilled weaving techniques. The result is a strong, versatile fabric that excels in handling a wide range of filtration, separation, and containment tasks.

Understanding Dutch Weave Wire Mesh

The construction of Dutch weave wire mesh involves a two-phase weaving process. The first phase uses fine wires that run vertically (the warp), while thicker wires run horizontally (the weft). This combination creates a finer surface texture on one side while maintaining strength and flexibility on the other. The mesh's unique cross-sectional geometry significantly enhances its ability to trap solids while allowing liquids or gases to pass through, making it an ideal material for a variety of filtering applications.

Dutch weave wire mesh is available in several different grades and opening sizes. These variations allow users to select the appropriate mesh for their specific filtration needs, whether it’s for industrial processes, food production, or chemical separation. The mesh can be made from various materials, including stainless steel, carbon steel, and other alloys, which contribute to its resilience and resistance to corrosion.

Applications in Various Industries

One of the primary applications of Dutch weave wire mesh is in the oil and gas industry, where it is utilized for filtration purposes. In drilling operations, it helps to separate liquids from solid particles, ensuring that only clean fluid is circulated back into the system. This not only improves efficiency but also helps in maintaining the integrity of the equipment.

In the food and beverage industry, Dutch weave wire mesh plays a crucial role in ensuring product quality and safety. It is used in various processes such as brewing, where it effectively filters out unwanted particles to produce a refined product. Additionally, it can be employed in dairy processing to separate curds from whey, thus enhancing product quality.

dutch weave wire mesh

The chemical and pharmaceutical sectors also benefit from Dutch weave wire mesh. It is used for filtration in chemical reactors, where it helps maintain purity by removing unwanted particulates. In pharmaceutical applications, the mesh is crucial for ensuring that end products are free from contaminants, a necessity for compliance with strict regulatory standards.

Advantages of Dutch Weave Wire Mesh

One of the major advantages of Dutch weave wire mesh is its high strength-to-weight ratio, making it suitable for rigorous applications without compromising on flexibility. Its robust structure allows it to withstand high pressures and temperatures, making it a reliable choice for industries that demand high-performance filtration materials.

Furthermore, the mesh is easy to clean and maintain, which is essential in industries where hygiene is critical. Its ability to resist corrosion, especially when made from stainless steel, extends its service life, reducing the need for frequent replacements and lowering operational costs over time.

The adaptability of Dutch weave wire mesh further enhances its appeal. It can be manufactured in various sizes and shapes, tailored to meet the specific needs of different applications. The woven characteristics provide high particle retention rates while maintaining optimal flow rates, ensuring operational efficiency across a range of applications.

Conclusion

In conclusion, Dutch weave wire mesh stands out as a superior filtration solution across multiple industries. Its unique construction, combined with its versatility and durability, makes it an essential material for companies striving for quality and efficiency in their processes. Whether in oil and gas, food and beverage, or pharmaceuticals, the intricate balance of strength and flexibility offered by Dutch weave wire mesh ensures optimal performance, making it an invaluable asset in modern manufacturing and production. As industries continue to evolve, the demand for effective filtration solutions like Dutch weave wire mesh is likely to grow, cementing its place as a critical component in various applications.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

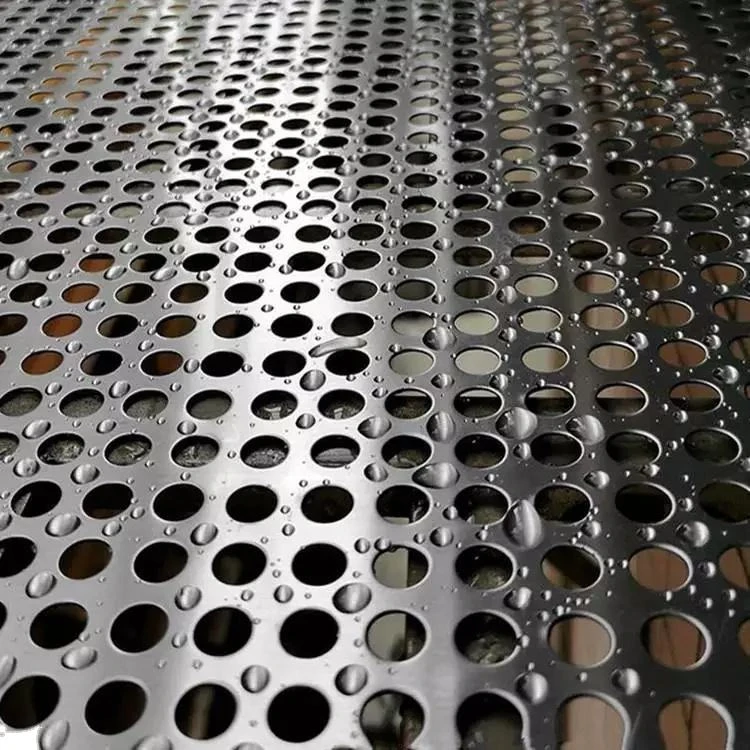

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.