Dutch Weave Wire Mesh An Overview of Its Applications and Benefits

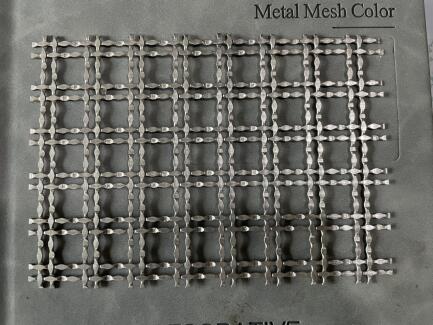

Dutch weave wire mesh is a specialized type of wire mesh that has gained significant attention in various industries due to its unique structure and versatile applications. Characterized by its tightly woven wires, this mesh is made using a combination of straight and crimped wires, creating a distinctive pattern that provides both strength and durability. It is particularly favored for its ability to filter particles of different sizes while maintaining excellent rigidity and stability.

Structure and Manufacturing Process

The manufacturing process of Dutch weave wire mesh involves weaving wires of varying diameters, which contributes to its exceptional strength and filtering capabilities. Typically, the mesh consists of a finer lower wire and a thicker upper wire, with the upper wire woven in a way that protects the finer wire, enhancing the entire structure’s durability. The mesh is produced in a range of thicknesses and aperture sizes, allowing for a custom approach depending on the specific needs of applications.

Applications of Dutch Weave Wire Mesh

1. Filtration One of the primary applications of Dutch weave wire mesh is in the filtration process, particularly in industries where finer filtration is required. It is widely used in the oil and gas sector for separating solids from liquids, as well as in water treatment facilities to filter out impurities. Its fine openings allow it to capture small particles while preventing clogging, making it ideal for use in various filtration systems.

2. Mining and Mineral Processing In the mining industry, Dutch weave wire mesh serves an essential role in separating different mineral grades. Its robust nature allows it to withstand harsh conditions, while its precise mesh size ensures effective sorting of various materials.

3. Pharmaceuticals and Food Processing The pharmaceutical and food industries require stringent standards for cleanliness and contamination prevention. Dutch weave wire mesh meets these needs by providing a dependable barrier against contaminants while allowing for effective processing of ingredients. Additionally, its ease of cleaning and durability makes it suitable for processes that require frequent maintenance.

dutch weave wire mesh

4. Aerospace and Manufacturing In industries such as aerospace, where lightweight yet strong materials are critical, Dutch weave wire mesh is utilized in the production of components that require high strength-to-weight ratios. The mesh enhances structural integrity while contributing minimal additional weight.

5. Architecture and Design Beyond industrial applications, Dutch weave wire mesh is also employed in architectural designs. Its flexibility, combined with aesthetic appeal, allows it to be used in artistic installations, façades, and interior design features, making it an attractive choice for modern architecture.

Benefits of Dutch Weave Wire Mesh

The advantages of using Dutch weave wire mesh are manifold. One of the most significant benefits is its exceptional strength, allowing it to withstand significant pressure and stress without compromising its structural integrity. This makes it ideal for high-demand applications where safety and reliability are paramount.

Additionally, its precise mesh openings enable precise filtration capabilities, ensuring that specific particles are effectively screened out. This can result in improved process efficiencies, reduced maintenance costs, and better overall product quality in various processes.

The durability of Dutch weave wire mesh also contributes to its longevity, reducing the need for frequent replacements and minimizing operational disruptions. With its resistance to wear and tear, it remains a cost-effective solution in the long run, offering both economic and functional benefits.

Conclusion

In summary, Dutch weave wire mesh emerges as a versatile and valuable material across multiple industries. Whether it is in filtration applications, mineral processing, or architectural designs, its strength, durability, and filtering capabilities make it an indispensable tool. As industries continue to evolve, the demand for efficient and reliable materials like Dutch weave wire mesh will undoubtedly increase, further solidifying its position as a cornerstone in modern manufacturing and design.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.