Understanding Dutch Weave Screens A Comprehensive Guide

Dutch weave screens are an essential component in various industrial applications, renowned for their unique construction and exceptional filtering capabilities. These woven mesh materials are primarily used in industries such as oil and gas, food processing, pharmaceuticals, and water treatment. This article delves into the design, benefits, and applications of Dutch weave screens, highlighting why they have become a preferred choice in modern filtration solutions.

What is Dutch Weave?

Dutch weave refers to a specific type of weaving technique where wires are interlaced in a unique pattern, creating a mesh that is both durable and effective for filtration. The construction typically involves two sets of wires the warp wires (the vertical wires) and the weft wires (the horizontal ones). In Dutch weave, the weft wires are thicker than the warp wires, resulting in a structure that is denser and more robust than traditional woven meshes. This design allows for smaller openings, making it ideal for applications requiring precise filtration.

The weaving process is meticulously engineered. The wires are tightly woven together, reducing the size of the openings and enhancing the screen's strength. This method results in a mesh that can sustain high pressures and temperatures, a critical requirement in many industrial environments.

Key Benefits of Dutch Weave Screens

1. High Filtration Efficiency One of the primary advantages of Dutch weave screens is their ability to filter out particulates effectively. The reduced aperture size allows for the separation of fine particles from liquids or gases, which is crucial in many industries.

2. Strength and Durability Thanks to the robust construction of Dutch weave screens, they exhibit excellent mechanical strength. These screens can withstand harsh operational conditions, including extreme temperatures and pressures, making them ideal for challenging applications.

3. Resistance to Corrosion Dutch weave screens are often manufactured from stainless steel or other corrosion-resistant materials. This property is vital for applications in harsh environments, such as chemical processing, where exposure to corrosive substances is common.

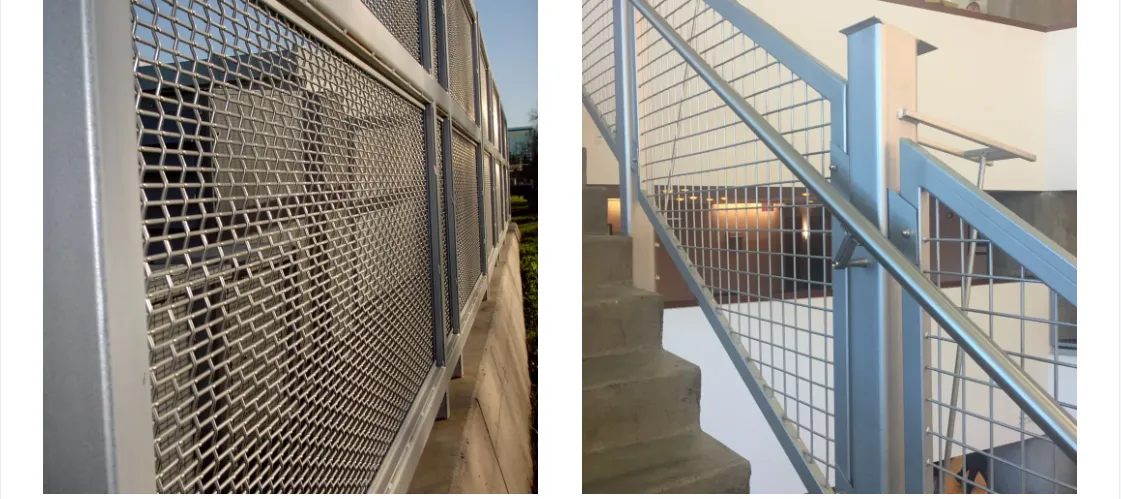

dutch weave screen

4. Versatility Dutch weave screens can be customized to meet specific filtration needs. Various mesh sizes and thicknesses can be produced depending on the intended application, making them versatile tools for a wide range of industries.

5. Easy Cleaning and Maintenance Due to their robust construction and smooth surface, Dutch weave screens are relatively easy to clean, allowing for maintenance and prolonged use without significant degradation in performance.

Applications of Dutch Weave Screens

The applications of Dutch weave screens span multiple sectors. In the oil and gas industry, they are commonly used in sand control and filtration processes. Their high degree of filtration is crucial for preventing particulates from damaging sensitive equipment.

In the food and beverage industry, Dutch weave screens play a vital role in the clarification and filtration of liquids, ensuring that the final products are free from impurities. Similarly, in the pharmaceutical industry, these screens are used in filtration systems to maintain the purity of medications.

Water treatment facilities also rely on Dutch weave screens for efficient filtration, effectively removing contaminants and ensuring clean water supply for both industrial and residential use.

Conclusion

Dutch weave screens exemplify the intersection of innovative engineering and practical application in filtration technology. Their unique design offers unmatched filtration efficiency, durability, and resistance to corrosive environments. As industries continue to evolve and demand higher standards for filtration, Dutch weave screens stand out as a reliable solution, ready to meet the challenges of modern applications. Whether in oil and gas, food processing, or water treatment, these screens are an indispensable part of the filtration landscape, ensuring efficiency and quality in diverse operations.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.