The Importance and Applications of Welded Wire Mesh Guardrail

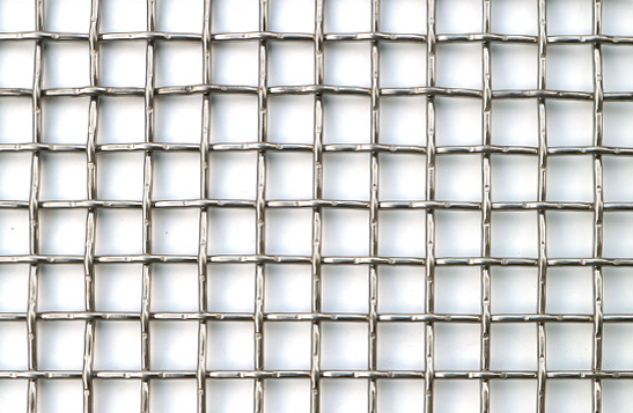

In the realm of highway safety and urban development, welded wire mesh guardrails have emerged as an effective solution for securing defined spaces and protecting pedestrians. These guardrails are constructed from low carbon steel wires that are welded together to create a grid-like pattern, providing strong support while maintaining visibility and airflow.

Durability and Strength

One of the most significant advantages of welded wire mesh guardrails is their durability. The welding process enhances the tensile strength of the wires, making them capable of withstanding harsh weather conditions and impacts from vehicles or obstacles. This strength is crucial, especially in high-traffic areas where the potential for accidents is higher. Furthermore, the use of galvanized steel in the manufacturing process ensures resistance to corrosion, extending the lifespan of the guardrails and reducing maintenance costs over time.

Safety Applications

Welded wire mesh guardrails serve multiple purposes, primarily focused on safety. They are commonly used along highways, bridges, and in construction sites to prevent vehicles from veering off course. The guardrails act as a barrier that mitigates the risk of accidents by directing vehicles back onto the road. In urban settings, they are also utilized around parks, playgrounds, and school zones to protect pedestrians and children from potential dangers.

Additionally, the visibility of these guardrails is advantageous when compared to solid barriers. The mesh design allows for better sightlines and ensures that drivers can see what lies beyond the guardrail, thereby minimizing the feeling of confinement that solid barriers might create. This is particularly important for mental health and anxiety levels of drivers, offering a sense of openness while still ensuring safety.

welded wire mesh guardrail

Versatility

Welded wire mesh guardrails are versatile and can be adapted for various applications. They can be easily shaped and installed to fit different terrains, making them suitable for rural, urban, and industrial applications alike. Moreover, these guardrails can be coated in different colors, allowing them to blend into their environment or stand out as a safety feature.

In addition to roads and highways, they are commonly used in agricultural settings to keep livestock contained and in industrial settings as fencing around hazardous areas. The versatility of welded wire mesh allows it to be customized in height and density, accommodating specific safety needs depending on the location and purpose.

Environmental Considerations

With a growing emphasis on sustainability, the environmental impact of construction materials is an increasingly vital issue. Welded wire mesh guardrails are often made from recyclable materials, making them an eco-friendly choice. Their longevity reduces the frequency of replacements, thus minimizing waste. Moreover, the open design of welded wire mesh allows for local flora and fauna to thrive, contributing positively to the environment in which they are installed.

Conclusion

In conclusion, welded wire mesh guardrails represent an essential component of modern safety infrastructure. Their durability, strength, and versatility position them as a preferred option for protecting both people and vehicles in a variety of settings. As cities and rural areas continue to develop, the need for effective safety measures grows, making it imperative to invest in reliable solutions like welded wire mesh guardrails. Their contribution to safety, combined with environmental benefits, makes them a responsible choice for future infrastructure projects.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.