Understanding Perforated Metal Mesh Sheet Technology

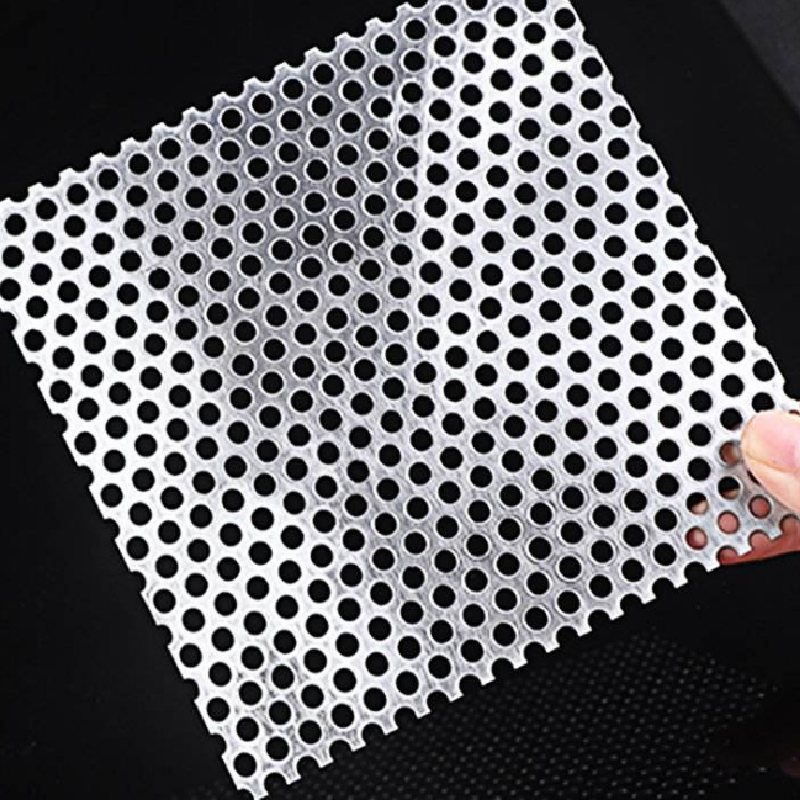

The industrial landscape continually demands materials that offer an optimal balance of strength, ventilation, aesthetics, and cost-effectiveness. In this critical context, the perforated metal mesh sheet stands out as a versatile and indispensable solution across numerous sectors. From architectural facades to intricate filtration systems, its engineered design provides specific functional benefits, including airflow management, sound attenuation, security, and decorative appeal. This comprehensive overview delves into the intricate details of its manufacturing, technical specifications, diverse applications, and strategic advantages for B2B decision-makers.

Modern manufacturing techniques allow for an unprecedented degree of customization, enabling engineers and designers to specify precise hole patterns, sizes, and materials to meet exacting project requirements. This adaptability makes perforated metal mesh sheet a cornerstone material for innovative solutions in challenging environments.

The Manufacturing Process Flow: From Raw Material to Finished Product

The production of perforated metal mesh sheet is a precision-driven process, ensuring high-quality, consistent products. The primary materials often include carbon steel, galvanized steel, stainless steel (e.g., 304, 316), aluminum, copper, and various alloys, each selected for its specific mechanical properties and corrosion resistance.

Key Steps in Perforated Metal Manufacturing:

- Material Selection & Preparation: High-grade metal sheets or coils are chosen based on application requirements. For instance, galvanized steel is preferred for outdoor applications like fencing due to its enhanced corrosion resistance, while stainless steel is crucial for hygiene-sensitive or high-temperature environments.

- Punching/Perforation: This is the core process, typically performed using high-speed CNC punching machines. A programmed die system rapidly punches holes into the metal sheet. Precision tooling ensures consistent hole size, pitch (distance between hole centers), and pattern (round, square, slotted, ornamental). Laser cutting is employed for intricate patterns or when material thickness or hardness makes punching unfeasible, allowing for highly complex laser cut perforated metal panels.

- Flattening & Deburring: The punching process can introduce stresses and burrs. Sheets undergo flattening to restore flatness and deburring to remove sharp edges, ensuring safety and a smooth finish.

- Cutting & Shearing: The perforated material is cut to specified dimensions using industrial shears or saws.

- Forming & Fabrication (Optional): Depending on the application, the perforated sheet may undergo further forming processes like bending, rolling, or welding to create finished components such as panels, tubes, or guards. This is particularly relevant for products like perforated metal grating or custom enclosures.

- Surface Treatment: To enhance durability, aesthetics, and corrosion resistance, various finishes are applied:

- Galvanization: Hot-dip or electro-galvanizing provides a zinc coating for superior rust protection, ideal for the 3D Galvanized Steel Material Perforated Metal Sheet for Fencing.

- Powder Coating: Offers a wide range of colors and an extra layer of protection against weathering and abrasion.

- Anodizing: For perforated metal aluminum sheet, this process creates a durable, corrosion-resistant oxide layer.

- Polishing: Especially for stainless steel, to achieve a high-gloss finish.

- Quality Control & Testing: Throughout the process, adherence to standards like ISO 9001 and ASTM E2738-10 (Standard Test Method for Hole Size and Pitch of Perforated Plate and Sheet) is critical. Testing includes dimensional accuracy, hole integrity, flatness, and surface finish.

Target industries benefiting from these processes include petrochemical (for filters and screens), metallurgy (for sieves and heat exchangers), water supply & drainage (for filtration and gratings), HVAC (for diffusers and grilles), and architectural design. The advanced manufacturing ensures advantages such as energy saving through optimized airflow, superior corrosion resistance, and extended service life, often exceeding 20-30 years with proper material selection and maintenance.

Industry Trends and Technical Specifications

Current trends in the perforated metal mesh sheet industry are driven by demands for increased sustainability, advanced aesthetic integration, and enhanced functional performance. The market sees a growing emphasis on lighter materials, intricate patterns enabled by sophisticated laser cutting, and innovative applications in green building and noise control.

Key Technical Parameters:

- Material Type: Stainless steel (304, 316), Carbon steel, Galvanized steel, Aluminum, Copper, Brass, Titanium.

- Gauge/Thickness: Typically ranges from 0.5mm to 10mm, influencing strength and weight.

- Hole Size: From 0.5mm to 100mm, dictating filtration capabilities and visual transparency.

- Hole Pattern: Round (most common), Square, Slotted, Hexagonal, Decorative.

- Pitch: The distance from the center of one hole to the center of the next, crucial for open area calculation.

- Open Area: Expressed as a percentage, indicating the total area of the holes divided by the total area of the sheet. Critical for airflow, light transmission, and filtration efficiency.

- Margin: The unperforated area along the edges of the sheet, important for structural integrity and mounting.

Product Specification Table: 3D Galvanized Steel Material Perforated Metal Sheet for Fencing

| Parameter | Specification | Notes |

|---|---|---|

| Material | Q235 Galvanized Steel | High tensile strength, superior corrosion resistance |

| Thickness | 1.0 mm - 5.0 mm | Customizable based on structural load and application |

| Hole Shape | Round, Square, Hexagonal, Slotted | Standard and custom patterns available |

| Hole Diameter | 3 mm - 30 mm | Optimal for security and visibility in fencing |

| Pitch | 5 mm - 50 mm | Determines open area and rigidity |

| Open Area | 20% - 70% | Balancing visibility, airflow, and privacy |

| Sheet Size | 1000x2000mm, 1220x2440mm, etc. | Custom sizes and coils available |

| Surface Treatment | Hot-dip Galvanized, Powder Coated | Enhanced durability and aesthetic appeal |

| Standards | ISO 9001, ASTM A123 | Ensuring quality and performance |

Application Scenarios and Technical Advantages

The versatility of perforated mesh sheet metal allows it to be deployed across a vast spectrum of applications, each leveraging its unique functional and aesthetic properties. Its ability to manage light, air, and sound, while offering structural integrity, makes it invaluable.

Common Application Areas:

- Architectural: Facades, sunscreens, ceiling panels, balustrades, and stair infills. The aesthetic appeal and light control are paramount.

- Industrial: Filtration screens, machine guards, ventilation covers, conveyor systems, and acoustic panels in factories. Products like metal perforated mesh are vital for safety and operational efficiency.

- Security & Fencing: Perimeter fencing, gates, and security screens, particularly using galvanized steel for enhanced anti-corrosion properties and strength against forced entry, as exemplified by our 3D Galvanized Steel Material Perforated Metal Sheet for Fencing.

- Anti-Slip Surfaces: Specialized perforated metal anti slip tread plate for platforms, walkways, and ramps, offering superior grip in hazardous conditions.

- HVAC & Acoustics: Air diffusers, sound-absorbing panels, and grilles that optimize airflow and reduce noise pollution.

- Automotive: Grilles, filtration components, and exhaust system parts.

- Food & Beverage: Sieves, strainers, and drying trays in processing.

Technical Advantages:

- Weight Reduction: Perforated sheets are lighter than solid sheets of the same material and thickness, reducing structural load and shipping costs.

- Air and Light Permeability: Customizable open areas allow for precise control over ventilation, light diffusion, and privacy.

- Sound Attenuation: Effective in absorbing or diffusing sound waves, making them ideal for acoustic panels.

- Aesthetics: Offers a modern, clean look with various patterns and finishes, enhancing architectural design.

- Heat Dissipation: The holes allow for efficient airflow, aiding in cooling and heat management, particularly in electronic enclosures.

- Durability & Corrosion Resistance: When made from materials like galvanized steel or stainless steel and treated with appropriate finishes, these sheets offer exceptional longevity, even in harsh environments.

- Cost-Effectiveness: While initial cost might be higher than some alternatives, the long service life, reduced maintenance, and functional benefits offer significant long-term value.

Vendor Comparison and Customization Options

Choosing the right supplier for mesh perforated sheet is paramount for project success, reliability, and cost-efficiency. A reputable vendor offers not only competitive pricing but also consistent quality, advanced manufacturing capabilities, and dedicated customer support.

Key Factors for Vendor Comparison:

- Manufacturing Capabilities: Look for advanced CNC punching, laser cutting, and forming equipment.

- Material Expertise: A broad range of materials and finishes, ensuring the right solution for specific environments.

- Quality Certifications: ISO 9001, CE, and adherence to relevant ASTM or ANSI standards.

- Customization: Ability to produce custom hole patterns, sizes, shapes, and fabrication services.

- Lead Time & Logistics: Efficient production schedules and reliable shipping.

- Technical Support: Engineering assistance for design, material selection, and application advice.

- Reputation & Experience: Years in the industry, client testimonials, and case studies.

Product Comparison: Galvanized Steel vs. Stainless Steel Perforated Sheets

| Feature | Galvanized Steel (e.g., Q235, Hot-dip) | Stainless Steel (e.g., 304, 316) |

|---|---|---|

| Primary Advantage | Excellent corrosion resistance at lower cost, high strength | Superior corrosion, heat, and chemical resistance; aesthetic appeal |

| Corrosion Resistance | Good, especially in outdoor, non-acidic/alkaline environments (zinc coating) | Exceptional, ideal for harsh chemical, marine, and food-grade environments |

| Cost | More economical | Higher initial cost |

| Applications | Outdoor fencing, machinery guards, security screens, general construction | Food processing, pharmaceutical, chemical plants, architectural facades, marine |

| Weldability | Good, but zinc coating removal may be required for clean welds | Excellent, maintains integrity |

| Aesthetics | Can be painted or powder coated; standard metallic grey if untreated | Polished, brushed, or satin finishes; highly decorative |

Customized Solutions:

Beyond standard offerings, the true value of a specialist supplier lies in their ability to deliver tailored solutions. Customization for perforated metal mesh sheet includes:

- Unique Hole Patterns: Designing bespoke hole shapes or arrangements for specific airflow, light diffusion, or branding purposes.

- Specialized Materials & Alloys: Working with exotic metals or specific alloys to meet extreme temperature, chemical resistance, or strength requirements.

- Complex Fabrication: Integrating bending, welding, rolling, and other fabrication steps to deliver ready-to-install components.

- Advanced Finishing: Applying multi-layer powder coatings, specialized anodizing, or custom polishing for unique aesthetic and protective needs.

Application Case Studies & Customer Experience

Real-world applications demonstrate the practical advantages and reliability of perforated metal mesh sheet. Our decades of experience and strong partnerships with leading industrial clients underscore our commitment to excellence.

Case Study 1: Perimeter Security for Industrial Facility

- Challenge: A large petrochemical plant required a robust, high-security perimeter fence that could withstand harsh weather conditions and deter unauthorized access, while also allowing for some visibility for security monitoring.

- Solution: We supplied thousands of meters of our 3D Galvanized Steel Material Perforated Metal Sheet for Fencing. The material’s hot-dip galvanized coating provided exceptional resistance to corrosion from industrial pollutants and saline air. The specific hole pattern (small round holes with a low open area) offered high security and resistance to cutting, yet allowed security cameras to maintain an overview.

- Outcome: The client reported a significant enhancement in site security and a drastic reduction in maintenance due to the material’s durability and resistance to degradation. The rigid 3D structure provided additional strength and made climbing difficult.

Case Study 2: Acoustic Panels for a Commercial Office Building

- Challenge: A modern office building with open-plan layouts faced issues with excessive noise reverberation, impacting productivity and employee comfort.

- Solution: Custom-designed perforated metal mesh sheet panels, made from powder-coated aluminum with a specific open area and backed with sound-absorbing material, were installed as ceiling tiles and wall partitions. The specific perforation pattern was engineered to optimize sound wave dissipation.

- Outcome: Post-installation acoustic testing showed a 35% reduction in reverberation time, leading to a noticeable improvement in the office environment. The aesthetic appeal of the laser-cut patterns also contributed positively to the interior design.

Trustworthiness & Support: FAQ, Lead Times, Warranty

Establishing trust is paramount in B2B relationships. We ensure transparency in our processes, commitments, and support services.

Frequently Asked Questions (FAQ):

- Q: How do I choose the correct material for my perforated mesh sheet?

- A: Material selection depends on the application environment (e.g., exposure to moisture, chemicals, high temperatures), required strength, and budget. Our technical team can assist you in selecting the optimal material, such as galvanized steel for outdoor durability or stainless steel for corrosive settings.

- Q: What is the typical lead time for custom perforated metal mesh sheet orders?

- A: Standard product lead times are typically 7-14 business days. For highly customized or large-volume orders, lead times can range from 3-6 weeks, depending on complexity and current production schedules. We provide accurate lead time estimates upon quotation.

- Q: Can your perforated metal grating be used for heavy-duty industrial flooring?

- A: Yes, we specialize in heavy-gauge perforated metal for industrial flooring and walkways, including perforated metal anti slip tread plate. These are designed to meet specified load-bearing capacities and safety standards.

- Q: What kind of warranty do you offer on your products?

- A: We offer a comprehensive warranty against manufacturing defects and material failures under normal usage conditions. Specific warranty periods vary by product and material, typically ranging from 5 to 10 years for structural integrity and surface treatments. Detailed warranty terms are provided with each quotation.

Lead Time & Fulfillment:

Our streamlined production process, combined with robust supply chain management, ensures efficient order fulfillment. We maintain strong inventory of common materials and employ flexible manufacturing schedules to accommodate urgent requests where possible. For project planning, we recommend engaging early in the design phase to optimize lead times for custom specifications.

After-Sales Support & Customer Service:

Our commitment extends beyond delivery. We provide dedicated after-sales support, including technical assistance for installation, maintenance guidance, and prompt resolution of any product-related inquiries. Our team is available via phone, email, and dedicated account managers to ensure continuous client satisfaction. We value long-term partnerships, built on trust and consistent performance.

Conclusion

The perforated metal mesh sheet is an engineering marvel, offering unparalleled versatility, durability, and aesthetic appeal for a myriad of industrial, architectural, and security applications. By understanding its intricate manufacturing process, technical specifications, and vast potential, B2B decision-makers can leverage this material to achieve superior project outcomes. Partnering with a knowledgeable and experienced manufacturer ensures access to high-quality, customized solutions that meet the most stringent industry standards and contribute to long-term operational efficiency and safety.

References

- ASTM International. (2010). ASTM E2738-10 Standard Test Method for Hole Size and Pitch of Perforated Plate and Sheet. Retrieved from www.astm.org

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements. Retrieved from www.iso.org

- American Galvanizers Association. (2020). The Durability of Hot-Dip Galvanized Steel. Retrieved from www.galvanizeit.org

- Euro Inox. (2018). Stainless Steel in Architecture, Building and Construction. Retrieved from www.euro-inox.org

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.