Understanding Galvanised Steel Grids Benefits and Applications

Galvanised steel grids are increasingly popular in various industrial, commercial, and residential applications due to their durability, strength, and corrosion resistance. These grids, made from steel that has been coated in a layer of zinc, provide a reliable and long-lasting solution for a variety of construction and design needs. This article explores the advantages of galvanised steel grids and their common applications.

What is Galvanised Steel?

Galvanised steel refers to steel that has undergone a galvanisation process, which involves coating the surface with zinc. This zinc coating serves as a protective barrier against corrosion and rust, which can significantly extend the life of steel products. The galvanisation process typically includes hot-dip galvanising or electro-galvanising, each providing a different thickness of zinc coating and varying protection levels.

Advantages of Galvanised Steel Grids

1. Corrosion Resistance One of the primary benefits of using galvanised steel grids is their exceptional resistance to corrosion. The zinc layer protects the underlying steel from environmental elements, moisture, and chemicals that would otherwise lead to deterioration. This makes galvanised steel grids ideal for outdoor and high-moisture applications.

2. Strength and Durability Galvanised steel grids possess high tensile strength and durability. They can support significant loads without bending or breaking, making them suitable for various structural support applications. This strength is particularly advantageous in heavy-duty environments like warehouses and industrial facilities.

3. Low Maintenance Because of their corrosion-resistant properties, galvanised steel grids require minimal maintenance. Unlike untreated steel which may need regular painting or sealing to prevent rust, galvanised steel grids can often be left unattended for years, reducing long-term maintenance costs and efforts.

4. Versatility Galvanised steel grids come in various configurations, sizes, and load-bearing capacities, allowing them to be tailored for specific applications. This versatility makes them suitable for many industries, including construction, agriculture, transportation, and more.

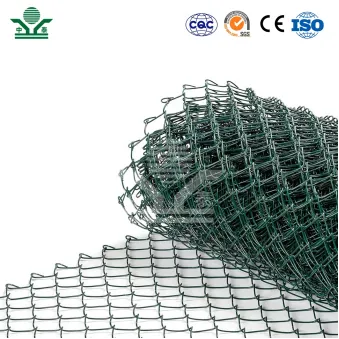

galvanised steel grid

5. Aesthetic Appeal In addition to their functional benefits, galvanised steel grids offer an industrial aesthetic that can be visually appealing in contemporary architecture and design. Their clean lines and metallic finish can complement modern design elements effectively.

Common Applications of Galvanised Steel Grids

- Walkways and Platforms Galvanised steel grids are commonly used to create safe walkways and platforms in industrial settings. Their non-slip surface and high strength make them ideal for areas where personnel and equipment movement is frequent.

- Drainage Systems In civil engineering, galvanised steel grids are often used in drainage systems, such as grates and covers. Their corrosion resistance ensures longevity in environments exposed to water and chemicals.

- Rooftop Structures Many buildings incorporate galvanised steel grids for rooftop access and safety. These grids support equipment such as HVAC systems while providing a safe work surface for maintenance personnel.

- Storage Solutions In warehouses, galvanised steel grids are often used for shelving and storage solutions. The strong, grid-like structure allows for optimal storage of materials while providing visibility and access.

Conclusion

Galvanised steel grids are a versatile and practical choice for a wide range of applications. Their durability, low maintenance requirements, and resistance to corrosion make them a valuable component in many industries. As architectural and engineering needs evolve, the use of galvanised steel grids is likely to expand, cementing their place as a cornerstone of modern construction and design. Whether for a large industrial project or a small residential upgrade, galvanised steel grids offer both functionality and aesthetic appeal.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.