Feb . 04, 2025 00:48

Back to list

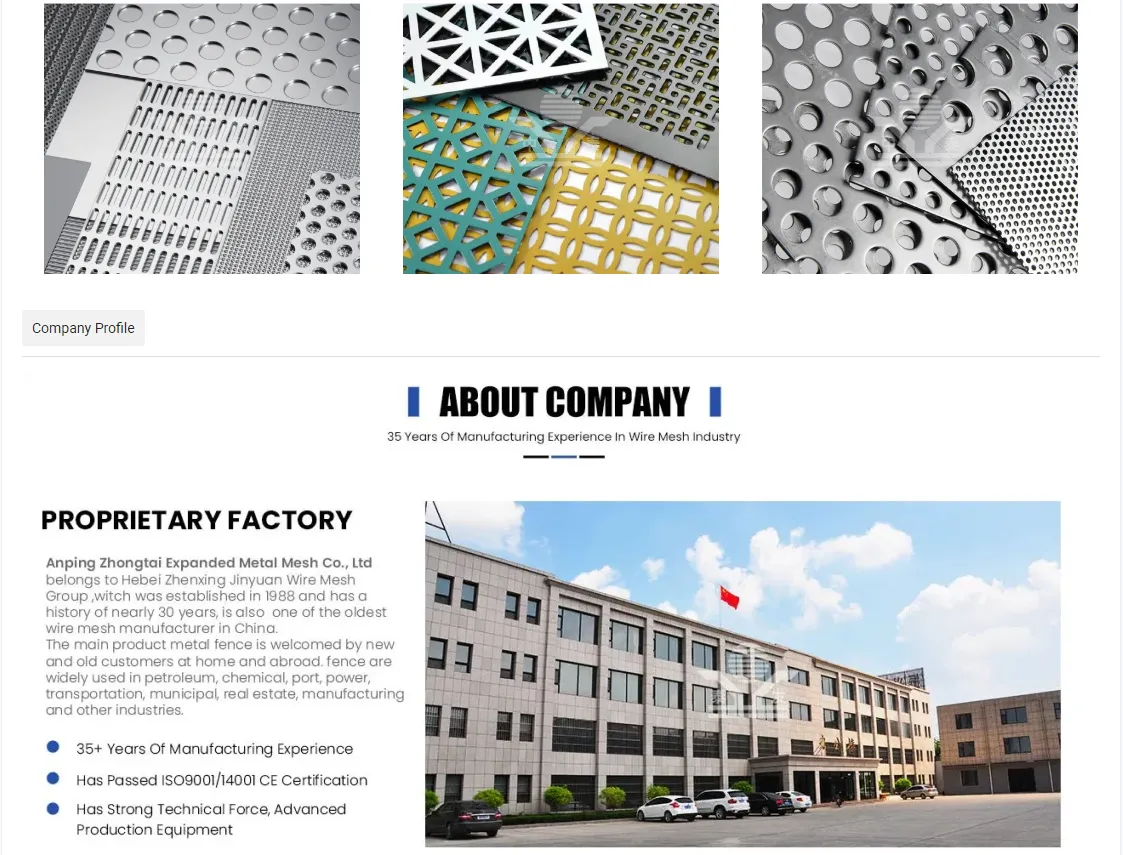

dimple perforated sheet

Dimple perforated sheets are an innovative solution with a plethora of applications across various industries. Their unique structure not only enhances functionality but also augments the aesthetic appeal of products. Companies that have integrated dimple perforated sheets into their product lines have witnessed a remarkable improvement in both user experience and product performance.

From an expertise standpoint, it is crucial to understand the specific needs of the industry when selecting dimple perforated sheets. Companies must consider factors such as material type, sheet thickness, dimple size, and spacing, each impacting performance in different ways. Manufacturers often work closely with clients to offer customized solutions that meet precise specifications, ensuring that every component fits perfectly with the intended application. Trust in the quality and reliability of dimple perforated sheets is bolstered by rigorous testing and certification processes. Leading manufacturers adhere to strict industry standards, providing documentation and warranties that instill confidence in their products. Users can rely on these sheets knowing they comply with industry benchmarks for safety, performance, and sustainability. While the market is flooded with materials claiming exceptional performance, the track record and proven results provided by dimple perforated sheets position them as a reputable choice. They offer end-users peace of mind through their consistent quality and versatility, backed by an extensive history of successful implementations across diverse sectors. In conclusion, dimple perforated sheets stand out as a multifaceted product that bridges the gap between functionality and design. Their adaptability to different industries makes them a valuable asset, enabling businesses to enhance product performance while maintaining an aesthetic edge. As technological advancements continue, the potential applications for these innovative sheets are bound to expand, reinforcing their place as a staple in modern industrial and architectural design.

From an expertise standpoint, it is crucial to understand the specific needs of the industry when selecting dimple perforated sheets. Companies must consider factors such as material type, sheet thickness, dimple size, and spacing, each impacting performance in different ways. Manufacturers often work closely with clients to offer customized solutions that meet precise specifications, ensuring that every component fits perfectly with the intended application. Trust in the quality and reliability of dimple perforated sheets is bolstered by rigorous testing and certification processes. Leading manufacturers adhere to strict industry standards, providing documentation and warranties that instill confidence in their products. Users can rely on these sheets knowing they comply with industry benchmarks for safety, performance, and sustainability. While the market is flooded with materials claiming exceptional performance, the track record and proven results provided by dimple perforated sheets position them as a reputable choice. They offer end-users peace of mind through their consistent quality and versatility, backed by an extensive history of successful implementations across diverse sectors. In conclusion, dimple perforated sheets stand out as a multifaceted product that bridges the gap between functionality and design. Their adaptability to different industries makes them a valuable asset, enabling businesses to enhance product performance while maintaining an aesthetic edge. As technological advancements continue, the potential applications for these innovative sheets are bound to expand, reinforcing their place as a staple in modern industrial and architectural design.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP