Different Types of Wire Mesh A Comprehensive Overview

Wire mesh, a versatile material widely used across various industries, consists of a grid of metal wires that are interwoven to create a strong and durable structure. Its applications range from architectural elements to industrial uses, and each type of wire mesh offers unique benefits and specifications suited for different purposes. This article provides an overview of the different types of wire mesh, emphasizing their features, materials, and ideal applications.

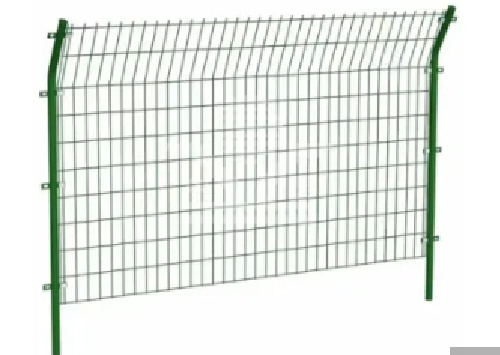

1. Welded Wire Mesh

Welded wire mesh is created by welding together intersecting wires at their junction points. This type of mesh is characterized by its uniform grid pattern and high tensile strength. Available in various wire gauges and mesh sizes, welded wire mesh is commonly used in construction, fencing, and reinforcement applications. Its rigid structure makes it an excellent choice for concrete reinforcement, as it provides consistent support and reduces the likelihood of cracking.

2. Woven Wire Mesh

Woven wire mesh is made by weaving wires together in a crisscross pattern, similar to a fabric. This type of mesh can be produced in various materials, including stainless steel, aluminum, and copper, offering flexibility in terms of strength and corrosion resistance. Woven wire mesh is often employed in filters, screens, and decorative applications due to its aesthetic appeal and customizable designs. Its open weave allows for excellent airflow and light transmission, making it suitable for applications such as animal enclosures and window screens.

Expanded metal mesh is produced by cutting and stretching a solid sheet of metal into a mesh configuration. This process allows the metal to maintain its strength while reducing weight. Expanded metal mesh is commonly used in walkways, platforms, and security fencing as it provides a slip-resistant surface and is capable of withstanding significant loads. The open design of expanded metal mesh allows for excellent visibility and airflow, making it an ideal choice for industrial applications where ventilation is necessary.

different types of wire mesh

4. Chain Link Fencing

Chain link fencing is a specific type of wire mesh used primarily for security and containment purposes. Made from interwoven steel wires, it forms a diamond pattern that is both strong and flexible. Chain link fencing is widely used in residential, commercial, and industrial settings to secure perimeters. Available in various heights and coatings (such as vinyl or galvanized), chain link fences are durable and require minimal maintenance, making them a popular choice for both temporary and permanent fencing solutions.

5. Perforated Metal Mesh

Perforated metal mesh is created by punching holes into a sheet of metal, resulting in a pattern of openings. This design allows for light, airflow, and drainage while maintaining strength and structural integrity. Perforated metal is often used in architectural applications, such as building facades, ceilings, and partitions, where aesthetics and functionality are both important. It is also commonly found in industrial settings for applications such as filtration and material handling.

6. Stainless Steel Wire Mesh

Stainless steel wire mesh is known for its corrosion resistance and durability. It is available in both welded and woven forms, making it suitable for a wide range of applications, including food processing, medical device manufacturing, and marine environments. The ability to withstand harsh conditions and exposure to chemicals makes stainless steel wire mesh a preferred choice in industries where hygiene and durability are critical.

Conclusion

In summary, wire mesh is an essential material with a multitude of types that cater to diverse applications. Whether you require the strength of welded wire mesh for construction, the flexibility of woven wire mesh for filtration, or the durability of stainless steel wire mesh for industrial use, each variation offers unique advantages. Selecting the right type of wire mesh depends on specific project requirements, including strength, durability, aesthetic appeal, and environmental resistance. Understanding the different types of wire mesh is crucial for making informed decisions that optimize performance and functionality in your projects.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.