Apr . 08, 2024 11:51

Back to list

Different Types of Expanded Metal expanded metal

As expanded metal has a high strength to weight ratio and is easy to use, it makes it ideal for many uses. Expanded metal can be used for security fencing, fence grating, walkways, ventilation systems as well as architectural or decorative purposes.

A wide variety of expanded metal is available, including flattened, standard (raised), grating, catwalk grating, and designer. Expanded metals have their own unique characteristics and advantages, which are why choosing the right expanded metal for a given application depends on such factors as strength, durability, and appearance. We will discuss all of these types in more detail, as well as their advantages and applications.

What Is Expanded Metal?

The origin of the expanded metal creation process dates back to the 1880s in Hartlepool, UK, where it was initially developed and copyrighted. Despite technological advancements, the contemporary method of expanding metal closely resembles the original technique.

Expanded metal is crafted from a solid metal sheet, with materials like stainless steel, aluminum, steel, titanium, and copper commonly used. The sheet undergoes cutting and stretching through industrial machinery, resulting in a mesh with diamond-shaped openings. Various other patterns can be achieved through this process.

The open-to-closed mesh area ratio determines the space available for light, air, and water passage, and this ratio can be tailored to suit specific mesh applications. Starting from a small steel sheet and culminating in the production of a large mesh, the process renders the material lightweight and cost-effective, making it an economical choice.

The versatility of expanded metal broadens its applications, finding use across various industries. While permitting the passage of air and light, expanded metal boasts robust strength and durability.

The diamond shape excels in energy absorption and exhibits minimal deformation after installation. Other design variations take into account the size and angles of the shapes, evaluating their capacity to absorb energy effectively.

Expanded metal is crafted from a solid metal sheet, with materials like stainless steel, aluminum, steel, titanium, and copper commonly used. The sheet undergoes cutting and stretching through industrial machinery, resulting in a mesh with diamond-shaped openings. Various other patterns can be achieved through this process.

The open-to-closed mesh area ratio determines the space available for light, air, and water passage, and this ratio can be tailored to suit specific mesh applications. Starting from a small steel sheet and culminating in the production of a large mesh, the process renders the material lightweight and cost-effective, making it an economical choice.

The versatility of expanded metal broadens its applications, finding use across various industries. While permitting the passage of air and light, expanded metal boasts robust strength and durability.

The diamond shape excels in energy absorption and exhibits minimal deformation after installation. Other design variations take into account the size and angles of the shapes, evaluating their capacity to absorb energy effectively.

How Is Expanded Metal Made?

The production of expanded metal commences with a metal sheet, undergoing cutting and stretching processes. These actions uniformly expand the cuts, forming diamond-shaped apertures. Notably, the expanding process generates no metal waste, rendering expanded metal an eco-friendly product. As previously mentioned, expanded metal originates from a single sheet of any metal. An industrial cutting machine traverses back and forth, making alternating cuts to achieve a specific shape. Various knife patterns can be employed to cut the sheet into diverse shapes and sizes. The primary objective of creating expanded metal is to stretch it, requiring only a small metal piece for the process.

Expanded metal machines serve multiple functions, with certain processes necessitating the use of multiple machines. The conventional approach involves expanding the metal sheet in a press to create diamond-shaped voids. Subsequently, a flattening machine is utilized to level the metal, followed by a shearing and slitting machine that cuts and forms the holes. The specific process may vary based on available resources and requirements.

Expanded metal machines serve multiple functions, with certain processes necessitating the use of multiple machines. The conventional approach involves expanding the metal sheet in a press to create diamond-shaped voids. Subsequently, a flattening machine is utilized to level the metal, followed by a shearing and slitting machine that cuts and forms the holes. The specific process may vary based on available resources and requirements.

Different Types of Expanded Metal

There are 5 main types of expanded metals: standard expanded metal, flattened expanded metal,designer expanded metal,expanded metal catwalk grating and expanded metal grating. They all start as a metal sheet, but evolve into their respective types.

What Is Standard (Raised) Expanded Metal?

Standard expanded metal, also known as raised expanded metal, proves to be a versatile material suitable for various applications. The distinctive raised pattern of diamond-shaped openings is achieved through the process of slitting and stretching the sheet metal. Standard expanded metal is ready for use after cutting, whereas additional manufacturing steps are required for flattened expanded metal.

This type of expanded metal is offered in diverse materials, including aluminum, carbon steel, galvanized steel, and stainless steel. It finds common usage in decorative and architectural features, filtration systems, and protective barriers.

A notable advantage of standard expanded metal lies in its generous open area percentage, facilitating improved airflow and visibility. The increased open area makes it an excellent choice for applications such as ventilation systems or security screenings. The raised diamond-shaped openings provide a non-slip surface, ensuring good traction and making it suitable for flooring in industrial and commercial areas.

The strength and durability of standard expanded metal further make it suitable for heavy-duty applications where safety and stability are paramount. In essence, standard expanded metal emerges as a versatile and enduring material, easily customizable to meet diverse application requirements.

This type of expanded metal is offered in diverse materials, including aluminum, carbon steel, galvanized steel, and stainless steel. It finds common usage in decorative and architectural features, filtration systems, and protective barriers.

A notable advantage of standard expanded metal lies in its generous open area percentage, facilitating improved airflow and visibility. The increased open area makes it an excellent choice for applications such as ventilation systems or security screenings. The raised diamond-shaped openings provide a non-slip surface, ensuring good traction and making it suitable for flooring in industrial and commercial areas.

The strength and durability of standard expanded metal further make it suitable for heavy-duty applications where safety and stability are paramount. In essence, standard expanded metal emerges as a versatile and enduring material, easily customizable to meet diverse application requirements.

What Is Flattened Expanded Metal?

Flattened expanded metal refers to a specific type of expanded metal that undergoes additional processing to achieve a flattened or smooth surface. The standard expanded metal, characterized by its raised pattern of diamond-shaped openings, is subjected to a flattening process to produce this variant.

The manufacturing process involves slitting and stretching a metal sheet, creating the raised pattern in standard expanded metal. To produce flattened expanded metal, the standard version undergoes a secondary process. This process typically involves passing the raised expanded metal through heavy rollers that flatten the surface, resulting in a smoother and level finish.

Flattened expanded metal shares similarities with its standard counterpart in terms of material options, including aluminum, carbon steel, galvanized steel, and stainless steel. However, the additional flattening step imparts unique characteristics to the flattened variant, making it suitable for specific applications.

The flattened surface offers benefits such as improved aesthetics, increased surface area for certain applications, and enhanced versatility in decorative and architectural uses. It retains the strength and durability associated with expanded metal while providing a different visual and functional profile compared to the standard raised pattern.

The manufacturing process involves slitting and stretching a metal sheet, creating the raised pattern in standard expanded metal. To produce flattened expanded metal, the standard version undergoes a secondary process. This process typically involves passing the raised expanded metal through heavy rollers that flatten the surface, resulting in a smoother and level finish.

Flattened expanded metal shares similarities with its standard counterpart in terms of material options, including aluminum, carbon steel, galvanized steel, and stainless steel. However, the additional flattening step imparts unique characteristics to the flattened variant, making it suitable for specific applications.

The flattened surface offers benefits such as improved aesthetics, increased surface area for certain applications, and enhanced versatility in decorative and architectural uses. It retains the strength and durability associated with expanded metal while providing a different visual and functional profile compared to the standard raised pattern.

What Is Designer Expanded Metal?

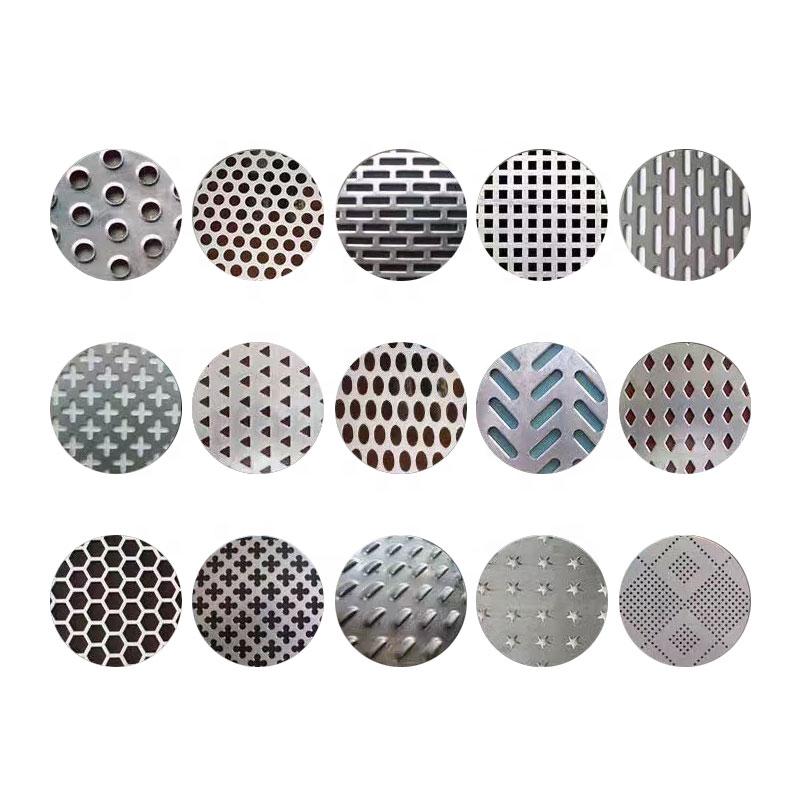

Designer expanded metal stands out with its distinctive patterns and designs, making it a perfect choice for architectural and decorative applications. Specifically crafted to produce unique and decorative patterns, this type of expanded metal can be customized to fulfill specific aesthetic or functional requirements. Unlike standard expanded metal with its typical diamond-shaped openings, decorative expanded metal features various shapes, textures, and designs.

Architects frequently incorporate designer expanded metal into building facades, decorative screens, and interior designs. Its versatility extends to applications like shading, security, and privacy. Available in materials such as stainless steel, aluminum, brass, and copper, designer expanded metal offers a range of options.

The manufacturing process for designer expanded metal involves cutting and stretching metal sheets to form a mesh-like structure, akin to the production of standard expanded metal. However, the process for designer expanded metal is more precise and controlled to achieve the desired intricate patterns. Additionally, the metal sheets used in designer expanded metal are typically thinner, providing greater flexibility and ease of manipulation.

The thinness of the metal enables the creation of more intricate designs, empowering architects and designers to fashion unique and detailed patterns. With its distinctive design, durability, and versatility, designer expanded metal proves to be an excellent choice for various architectural and decorative applications.

Architects frequently incorporate designer expanded metal into building facades, decorative screens, and interior designs. Its versatility extends to applications like shading, security, and privacy. Available in materials such as stainless steel, aluminum, brass, and copper, designer expanded metal offers a range of options.

The manufacturing process for designer expanded metal involves cutting and stretching metal sheets to form a mesh-like structure, akin to the production of standard expanded metal. However, the process for designer expanded metal is more precise and controlled to achieve the desired intricate patterns. Additionally, the metal sheets used in designer expanded metal are typically thinner, providing greater flexibility and ease of manipulation.

The thinness of the metal enables the creation of more intricate designs, empowering architects and designers to fashion unique and detailed patterns. With its distinctive design, durability, and versatility, designer expanded metal proves to be an excellent choice for various architectural and decorative applications.

What Is Expanded Metal Catwalk Grating?

Expanded metal catwalk grating comes in diverse sizes and thicknesses, offering customization options to fulfill specific application needs. Commonly crafted from materials like carbon steel, it can undergo galvanization to enhance resistance against corrosion, impact, and wear. The installation and maintenance of expanded metal catwalk grating are straightforward, contributing to its popularity across various industries such as construction, oil and gas, mining, and manufacturing.

What Is Expanded Metal Grating?

Designed for use as walkway or flooring material, expanded metal grating is favored by industries and businesses for its slip resistance, durability, and easy installation. It can be crafted from a range of materials, including carbon steel, stainless steel, and aluminum.

A notable advantage of expanded metal grating lies in its high load-bearing capacity. Featuring a robust design with larger patterns and thicker strands, it enhances strength and stability to accommodate heavy loads. Furthermore, the installation of expanded metal grating is straightforward. Customization options, such as cutting and secure attachment through fabrication methods like welding, contribute to its hassle-free installation.

A notable advantage of expanded metal grating lies in its high load-bearing capacity. Featuring a robust design with larger patterns and thicker strands, it enhances strength and stability to accommodate heavy loads. Furthermore, the installation of expanded metal grating is straightforward. Customization options, such as cutting and secure attachment through fabrication methods like welding, contribute to its hassle-free installation.

Benefits of Expanded Metal

Expanded metals boast numerous uses and offer several advantages, as outlined below:

1.Environmentally Friendly: Expanded metal is considered a green product due to its environmentally friendly manufacturing process. From raw material to the end product, minimal waste (scrap metal) is generated, contributing to its cost-effectiveness. The material is recyclable, providing an eco-friendly alternative to traditional metal sheets.

2.Permeability: The unique design of expanded metal allows air, fluid, or light to flow through, enabling the protection of an area without complete enclosure. This permeability ensures effective ventilation and visibility while maintaining security.

3.Slip-Resistant Surface: With its diamond-shaped openings, expanded metal facilitates the easy passage of air, water, fluid, and dirt, ensuring a safe and slip-resistant surface. This feature enhances its suitability for various applications, particularly those requiring traction.

4.Material Variety: Expanded metal can be crafted from a wide range of materials, including steel and other metals. This versatility allows for diverse applications, from small battery cells to heavy-duty shelves, catering to specific needs.

5.Strength and Flexibility: Made using steel, expanded metal exhibits unparalleled strength and flexibility. It boasts an exceptional strength-to-weight ratio, making it highly durable and capable of withstanding significant weight. This strength is particularly advantageous in applications requiring robust materials.

6.Customization Options: Expanded metal offers diverse customization options. Whether it's shaping or sizing, you can tailor it according to your specific requirements. Purchasing from reputable suppliers like Huijinmaterials Metals ensures access to a variety of options for a tailored solution.

1.Environmentally Friendly: Expanded metal is considered a green product due to its environmentally friendly manufacturing process. From raw material to the end product, minimal waste (scrap metal) is generated, contributing to its cost-effectiveness. The material is recyclable, providing an eco-friendly alternative to traditional metal sheets.

2.Permeability: The unique design of expanded metal allows air, fluid, or light to flow through, enabling the protection of an area without complete enclosure. This permeability ensures effective ventilation and visibility while maintaining security.

3.Slip-Resistant Surface: With its diamond-shaped openings, expanded metal facilitates the easy passage of air, water, fluid, and dirt, ensuring a safe and slip-resistant surface. This feature enhances its suitability for various applications, particularly those requiring traction.

4.Material Variety: Expanded metal can be crafted from a wide range of materials, including steel and other metals. This versatility allows for diverse applications, from small battery cells to heavy-duty shelves, catering to specific needs.

5.Strength and Flexibility: Made using steel, expanded metal exhibits unparalleled strength and flexibility. It boasts an exceptional strength-to-weight ratio, making it highly durable and capable of withstanding significant weight. This strength is particularly advantageous in applications requiring robust materials.

6.Customization Options: Expanded metal offers diverse customization options. Whether it's shaping or sizing, you can tailor it according to your specific requirements. Purchasing from reputable suppliers like Huijinmaterials Metals ensures access to a variety of options for a tailored solution.

Find the Best Expanded Metal Near You

Huijinmaterials offers a diverse selection of Expanded Metal, available in Aluminum, Carbon Steel, Stainless Steel, and Galvanized Steel. Committed to delivering top-notch services, Huijinmaterials prides itself on sourcing high-quality structural steel and plate products globally. The goal is to offer customers the broadest range of steel products, catering to various project requirements.

With nearly four decades of service, Huijinmaterials has become a reliable partner, ready to assist with diverse steel needs. The company maintains a comprehensive inventory of steel products to support a wide range of projects.

Additionally, Huijinmaterials is dedicated to providing steel-processing services to help customers meet stringent deadlines and reduce their investments in essential equipment. This commitment reflects the company's focus on customer satisfaction and efficient project execution.

With nearly four decades of service, Huijinmaterials has become a reliable partner, ready to assist with diverse steel needs. The company maintains a comprehensive inventory of steel products to support a wide range of projects.

Additionally, Huijinmaterials is dedicated to providing steel-processing services to help customers meet stringent deadlines and reduce their investments in essential equipment. This commitment reflects the company's focus on customer satisfaction and efficient project execution.

Latest news

-

Using Round Hole Mesh for Concrete Formwork Protection

NewsJul.09,2025

-

The Recyclability of Stainless Steel Mesh in a Circular Economy

NewsJul.09,2025

-

Steel Gratings in Green Construction Projects

NewsJul.09,2025

-

How Engineers Design Steel Structure Platforms for Maximum Safety

NewsJul.09,2025

-

Cable Mesh Railing for Rooftop Gardens and Terraces

NewsJul.09,2025

-

Aluminum Diamond Mesh: A Comprehensive Overview

NewsJul.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP