Feb . 04, 2025 05:49

Back to list

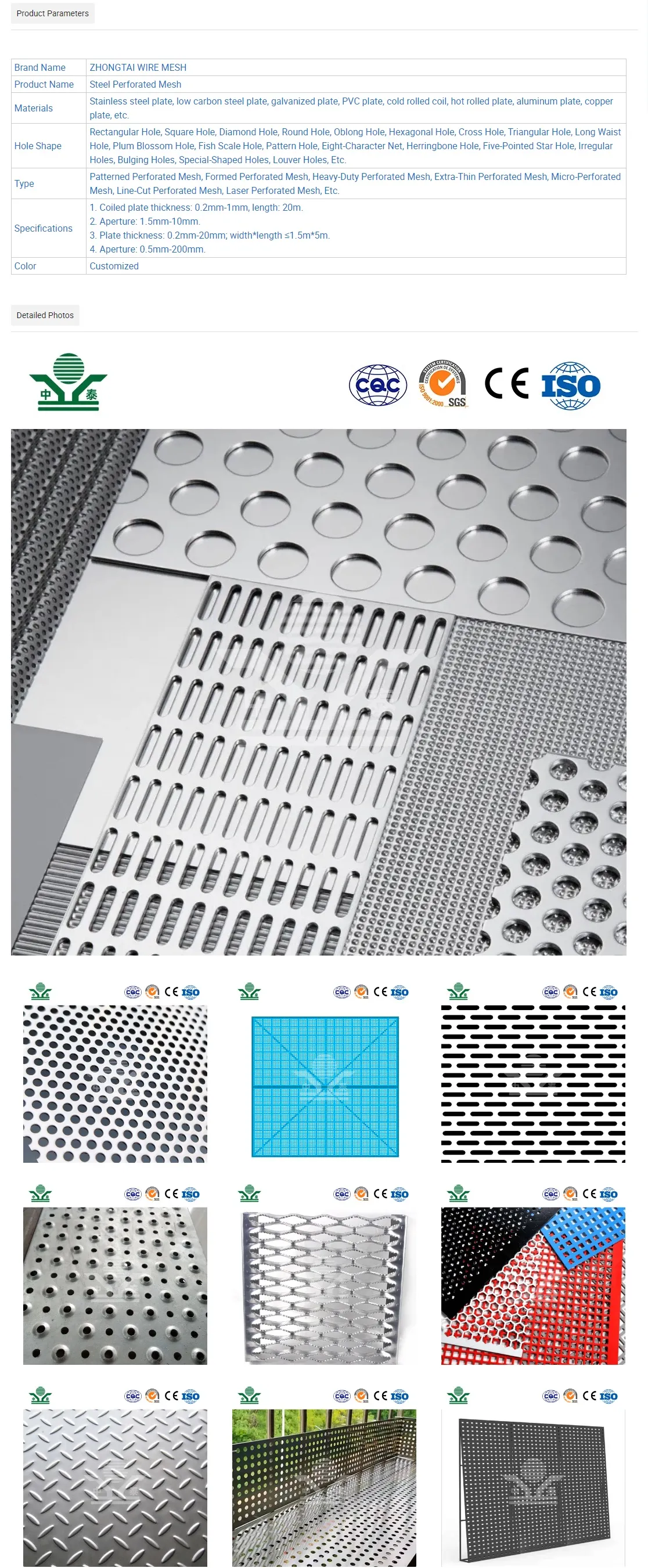

Round hole perforated mesh

Custom perforated sheet metal stands as a remarkable material solution across various industries, known for its versatility and functionality. Tailored to meet specific requirements, it intertwines design flexibility with structural durability, making it indispensable in architectural, industrial, and decorative applications. This metal's unique ability to blend form and function means it is not just another construction material but a vital component in modern engineering and design.

In achieving high standards of authoritativeness, suppliers of custom perforated sheet metal must adhere to rigorous testing and certification. This includes compliance with international standards for safety, durability, and environmental impact. Using verified quality control systems, these suppliers provide full transparency in their manufacturing processes, from sourcing raw materials to final shipment. For consumers and industries alike, this commitment to quality fosters trust, ensuring that they are investing in materials that will stand the test of time. The trustworthiness of custom perforated sheet metal also extends into its lifecycle. Metal is one of the most recyclable materials available, meaning that products can often be recycled at the end of their useful life without degradation to the material quality. This recyclability not only supports sustainable practices but also offers cost benefits to industries that rely on large volumes of metal. Moreover, suppliers who emphasize eco-friendly production methods contribute positively to their communities and the environment, further enhancing their reputation and reliability. Experience plays a pivotal role at every stage of the custom perforated sheet metal process. From the initial consultation and design phase through to production and final application, experienced professionals ensure seamless integration with existing systems and compliance with industry regulations. This depth of experience is invaluable, offering customers peace of mind and confidence in the solutions provided. Expertise in crafting customized solutions means addressing unique challenges with innovative designs, showcasing the limitless potential of this adaptable material. In essence, custom perforated sheet metal is more than a utility; it symbolizes a confluence of functionality and elegance. Its applications are as varied as the industries that rely on it, testament to its adaptability and enduring appeal. As technology and design continue to evolve, the scope and functionality of this unique material are set to grow, promising exciting developments for industries around the globe.

In achieving high standards of authoritativeness, suppliers of custom perforated sheet metal must adhere to rigorous testing and certification. This includes compliance with international standards for safety, durability, and environmental impact. Using verified quality control systems, these suppliers provide full transparency in their manufacturing processes, from sourcing raw materials to final shipment. For consumers and industries alike, this commitment to quality fosters trust, ensuring that they are investing in materials that will stand the test of time. The trustworthiness of custom perforated sheet metal also extends into its lifecycle. Metal is one of the most recyclable materials available, meaning that products can often be recycled at the end of their useful life without degradation to the material quality. This recyclability not only supports sustainable practices but also offers cost benefits to industries that rely on large volumes of metal. Moreover, suppliers who emphasize eco-friendly production methods contribute positively to their communities and the environment, further enhancing their reputation and reliability. Experience plays a pivotal role at every stage of the custom perforated sheet metal process. From the initial consultation and design phase through to production and final application, experienced professionals ensure seamless integration with existing systems and compliance with industry regulations. This depth of experience is invaluable, offering customers peace of mind and confidence in the solutions provided. Expertise in crafting customized solutions means addressing unique challenges with innovative designs, showcasing the limitless potential of this adaptable material. In essence, custom perforated sheet metal is more than a utility; it symbolizes a confluence of functionality and elegance. Its applications are as varied as the industries that rely on it, testament to its adaptability and enduring appeal. As technology and design continue to evolve, the scope and functionality of this unique material are set to grow, promising exciting developments for industries around the globe.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP