Understanding Perforated Steel Sheet Sizes

Perforated steel sheets are an essential material across various industries, offering unique properties and versatility for different applications. The size of these sheets plays a crucial role in determining their effectiveness in both aesthetic and functional applications. This article explores the various sizes of perforated steel sheets, their applications, and considerations for selecting the right size for your project.

What is a Perforated Steel Sheet?

A perforated steel sheet is a sheet of metal that has been mechanically punched to create a pattern of holes. These holes can vary in size, shape, and spacing, depending on the intended use of the sheet. The perforation process provides several benefits, including reduced weight, increased rigidity, and improved appearance.

Common Sizes and Standards

Perforated steel sheets are available in standard sizes, typically measured in feet or meters. The most common dimensions include sheets that are 4x8 feet or 5x10 feet. However, custom sizes can also be produced to meet specific project requirements.

The thickness of perforated steel sheets can vary, usually ranging from 18 gauge (approximately 1.2 mm) to 12 gauge (approximately 2.7 mm). The hole size and pattern are also customizable, with typical hole sizes ranging from 1/16 inch to 1 inch or more.

Applications of Perforated Steel Sheets

Perforated steel sheets are used in a myriad of applications. In the construction industry, they are commonly used for architectural facades, staircases, and railings. The holes allow for light and air to pass through while also providing necessary structural support.

In industrial settings, perforated sheets are used in the manufacturing of equipment, such as filters and screens, where airflow and fluid dynamics are critical. They are also frequently found in sound dampening applications, as the perforations can help reduce noise levels while still allowing for airflow.

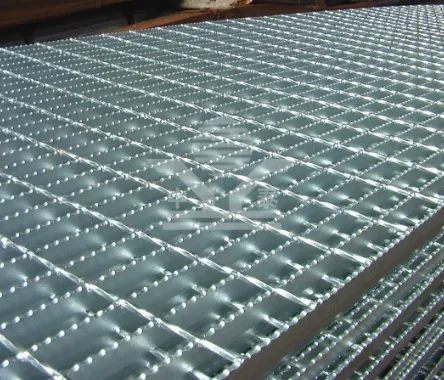

perforated steel sheet sizes

The energy sector utilizes perforated steel sheets in applications like solar panels and exhaust systems, where weight savings and thermal management are essential.

Choosing the Right Size

When selecting the appropriate size for a perforated steel sheet, there are several key factors to consider

1. Application The intended use of the sheet will dictate its size and hole pattern. For example, sheets used in filtration applications may require finer perforations compared to those used for decorative purposes.

2. Load Bearing If the sheet is part of a structural application, it's important to consider the weight it needs to support. Thicker sheets provide more strength, but may not be necessary in lighter applications.

3. Aesthetics The visual impact of perforated steel sheets is significant, especially in architectural designs. Different hole patterns can create various visual effects, so choosing the right one can enhance the overall appeal of the project.

4. Manufacturing Constraints Depending on the production capabilities of the manufacturer, custom sizes may come at an additional cost or with longer lead times. It is important to coordinate with suppliers to ensure that the selected size meets all logistical requirements.

Conclusion

Perforated steel sheets are versatile and highly functional materials that come in various sizes and specifications. Understanding the different sizes and their applications can help you make informed decisions as you plan your project. Whether you're looking for sheets for industrial use, architectural detailing, or any other application, the right size can significantly impact both the function and aesthetic of your design. Always consider the unique requirements of your project to ensure that you select the most suitable perforated sheet for your needs.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.