The Versatility and Applications of Carbon Steel Perforated Sheets

Carbon steel perforated sheets are a remarkable material that combines strength, durability, and versatility, making them a popular choice across various industries. These sheets consist of carbon steel that has been precisely perforated with a range of hole patterns, sizes, and configurations to meet diverse requirements. The unique characteristics of carbon steel, along with the advantages provided by perforation, make it an invaluable resource in manufacturing, construction, and design.

What is Carbon Steel?

Carbon steel is an alloy composed primarily of iron and carbon, where the carbon content typically ranges from 0.05% to 2.0% by weight. This alloy is renowned for its excellent mechanical properties, such as high tensile strength, impact resistance, and durability. The carbon content in steel impacts its hardness; for example, higher carbon content increases hardness but may also reduce ductility. Carbon steel can be categorized into low carbon, medium carbon, and high carbon steels, each serving distinctive applications.

Benefits of Perforated Sheets

Perforated sheets are created by punching holes into a flat sheet of material, resulting in a perforated pattern. The benefits of using carbon steel perforated sheets over traditional solid sheets include

1. Weight Reduction The removal of material through perforation leads to significant weight savings, which can be crucial in applications where weight is a concern, such as in aerospace or automotive industries.

2. Aesthetic Appeal Perforated sheets allow for creative designs by varying the hole sizes, patterns, and spacing. They can enhance the visual appeal of architectural designs, making them suitable for artistic applications.

3. Ventilation and Light Transmission The holes in perforated sheets facilitate air circulation and light penetration while maintaining structural integrity. This quality makes them ideal for applications like facades, screens, and partitions.

4. Acoustic Control Perforated sheets can help reduce noise levels in environments such as offices and concert halls. By strategically designing the perforation pattern, sound absorption can be optimized.

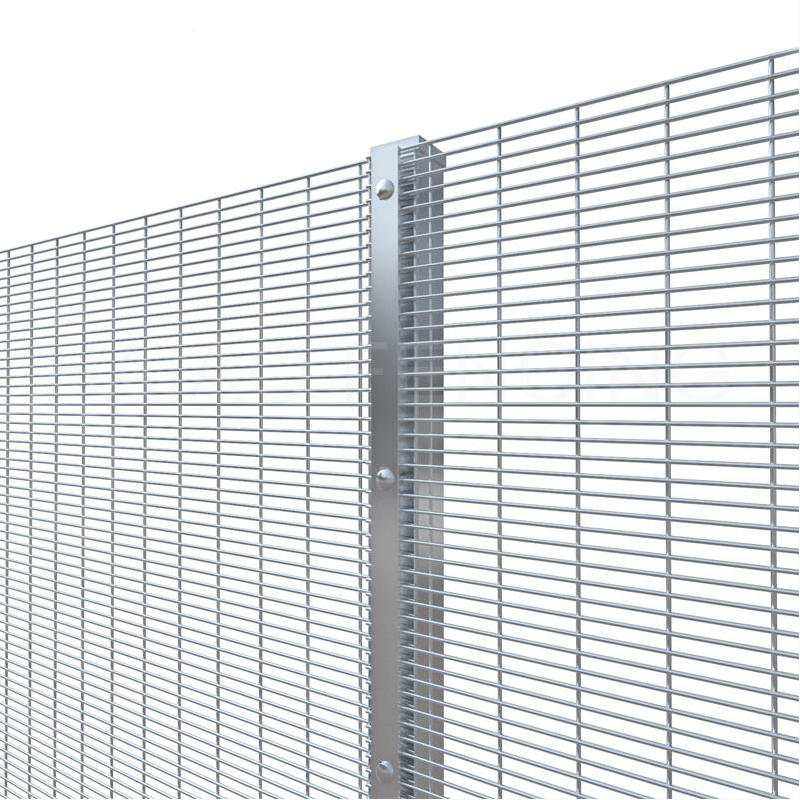

carbon steel perforated sheet

Applications of Carbon Steel Perforated Sheets

The versatility of carbon steel perforated sheets allows them to be utilized in numerous industries, including

1. Construction and Architecture In modern architecture, perforated sheets are used in façade designs, ceiling panels, and safety barriers. They provide aesthetic variety while serving functional roles such as sun shading and ventilation.

2. Industrial Manufacturing These sheets are extensively utilized in industries that require filtration and separation, such as in machinery, where they may serve as screens or guards to protect components from debris while allowing airflow.

3. Automotive Industry Carbon steel perforated sheets find use in automotive applications for grille designs, heat shields, and interior panels, benefiting from their lightweight nature without compromising strength.

4. Furniture Design Designers utilize perforated sheets for creating innovative furniture pieces, such as shelving units or room dividers that offer a contemporary look while promoting air circulation.

5. Food and Beverage Industry Perforated sheets play a crucial role in filtration systems, processing equipment, and storage solutions within the food and beverage sector, where hygiene and efficiency are paramount.

Conclusion

Carbon steel perforated sheets represent a blend of form and function, offering diverse solutions across a variety of sectors. Their intrinsic properties—strength, lightweight nature, and aesthetic flexibility—make them a preferred choice for architects, engineers, and designers alike. As industries continuously evolve, the demand for such versatile materials is only expected to rise, leading to innovations in design and application that leverage the unique advantages offered by carbon steel perforated sheets. Whether it’s enhancing structural integrity or adding aesthetic value, these perforated sheets continue to make significant contributions to modern engineering and construction practices.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.