Brass perforated metal sheets have become an increasingly popular choice in various applications due to their unique combination of elegance and functionality. Comprising brass, a copper-zinc alloy known for its corrosion resistance and aesthetic appeal, perforated metal sheets offer a variety of attributes that make them suitable for both industrial and decorative uses.

One of the standout features of brass perforated sheets is their striking appearance. The warm, golden hue of brass not only adds a touch of luxury but also provides a sophisticated backdrop for different design elements. This aesthetic quality makes brass perforated sheets highly sought after in architectural accents, interior design, and custom furnishings. From decorative screens and room dividers to lighting fixtures and furniture elements, the versatility of these sheets allows them to play a prominent role in enhancing visual appeal.

Moreover, brass perforated sheets offer exceptional functionality. The perforations allow for excellent airflow while maintaining privacy, making them ideal for applications such as ventilation grilles and barriers. They can also be used in acoustical panels to help control sound within various environments. In this way, they serve both practical and design purposes, creating spaces that are both functional and visually pleasing.

In industries like construction and manufacturing, brass perforated sheets are valued for their durability and resistance to wear and tear. Unlike other metals that may rust in humid or moist environments, brass retains its integrity, making it a reliable choice for outdoor applications, such as cladding and facades. Its strength ensures that it can withstand the rigors of daily use while maintaining its aesthetic qualities.

brass perforated metal sheet

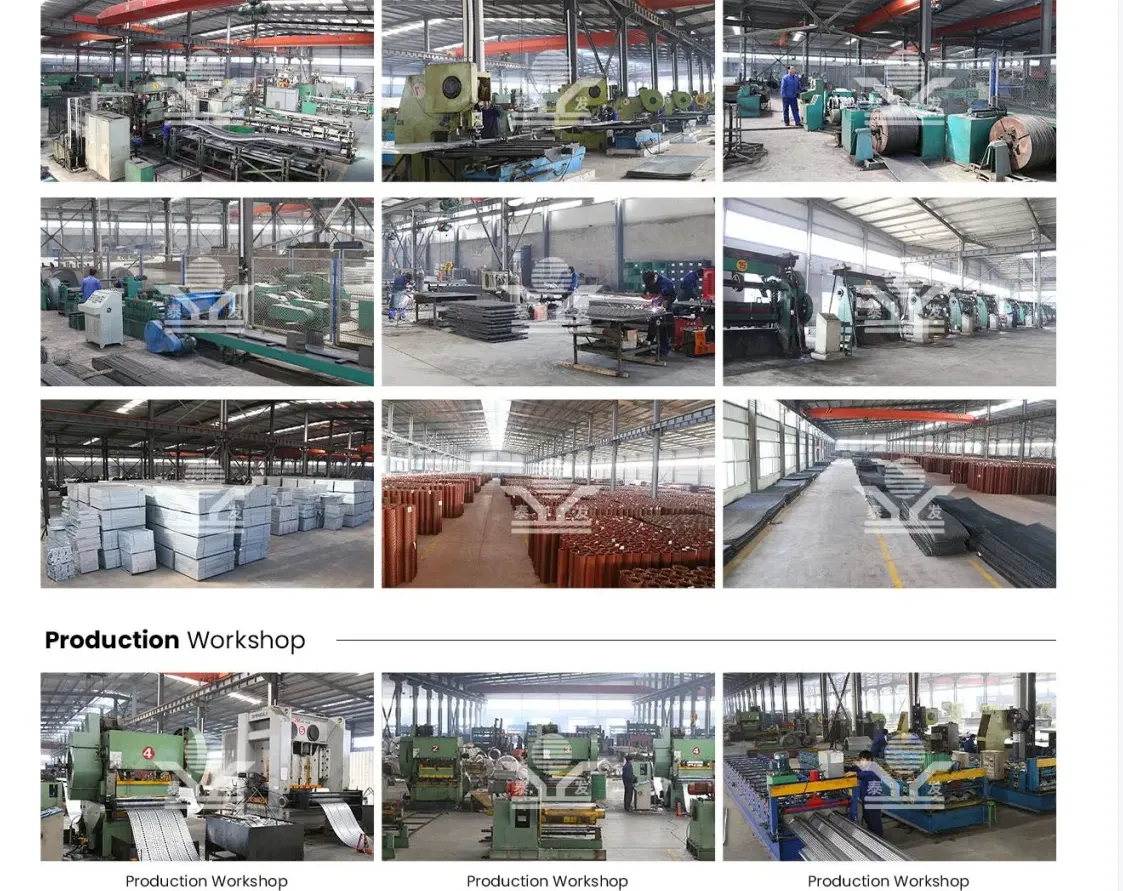

The manufacturing process for brass perforated sheets involves several key steps. First, a brass sheet is created, which is then subjected to a perforation process that creates uniform holes in specified patterns and sizes. This process can be tailored to meet specific project needs, allowing for creativity in design. Furthermore, the sheets can be finished with various techniques, such as polishing or coating, to enhance their resistance to tarnishing and to elevate their visual appeal.

Sustainability is another important consideration. Brass is a recyclable material, meaning that wasted sheets can be repurposed, reducing environmental impact. In a world increasingly focused on sustainability, utilizing brass perforated sheets contributes to eco-friendly practices in construction and design.

In conclusion, brass perforated metal sheets represent a perfect blend of form and function. Their elegant appearance, durability, and versatility make them an ideal choice for a wide range of applications, from decorative elements in residential spaces to robust solutions in industrial settings. As designers and builders continue to innovate, the use of brass perforated sheets will likely expand, highlighting their significance in both aesthetic and practical domains.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.