Understanding Bar Grating Prices Factors and Trends

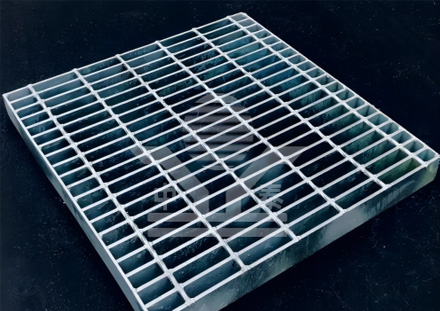

Bar grating, an essential component in various industrial applications, comes in various sizes, materials, and designs, all of which contribute to its pricing. Whether used for flooring, trench covers, or platforms, understanding the pricing dynamics of bar grating can help organizations make informed purchasing decisions.

Material Choices

The primary factor influencing bar grating prices is the material used in its production. Common materials include carbon steel, aluminum, and stainless steel, each offering distinct benefits and price points. Carbon steel is often the most economical option, making it ideal for applications where budget constraints are significant. However, it may require additional coatings or treatments to prevent rust and corrosion, which can add to the overall cost.

Stainless steel, while significantly more expensive, offers enhanced durability and resistance against harsh environments, making it suitable for facilities like chemical plants or food processing units. Aluminum grating, on the other hand, combines lightweight properties with corrosion resistance, appealing to industries that prioritize these characteristics despite potentially higher prices.

Design and Customization

bar grating prices

Another critical factor is the design of the grating. Standard designs may be less costly, but customized solutions, which are tailored to specific requirements or load capacities, typically come with a premium. The thickness of the bars, spacing between them, and loading capabilities all affect the final price. For example, heavier-duty options designed to support greater loads will inherently cost more due to the additional materials and engineering involved in their production.

Market Trends

Global supply chain trends also play a significant role in influencing bar grating prices. Fluctuations in raw material costs, tariffs, and availability can cause price volatility. Keeping abreast of these market conditions is essential for buyers; when demand surges—such as following infrastructure projects or expansions in manufacturing—the prices may increase accordingly.

Conclusion

In summary, when considering bar grating prices, it is essential to analyze the material, design, and prevailing market trends. Each project demands specific needs, and understanding these factors can help streamline the purchasing process and ensure you obtain the best value for your investment. Organizations should conduct thorough research and consult suppliers to navigate the complexities of bar grating pricing effectively. By doing so, they can minimize costs while ensuring they meet safety and durability standards crucial for their applications.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.