Understanding Aluminium Perforated Metal Sheets Applications and Benefits

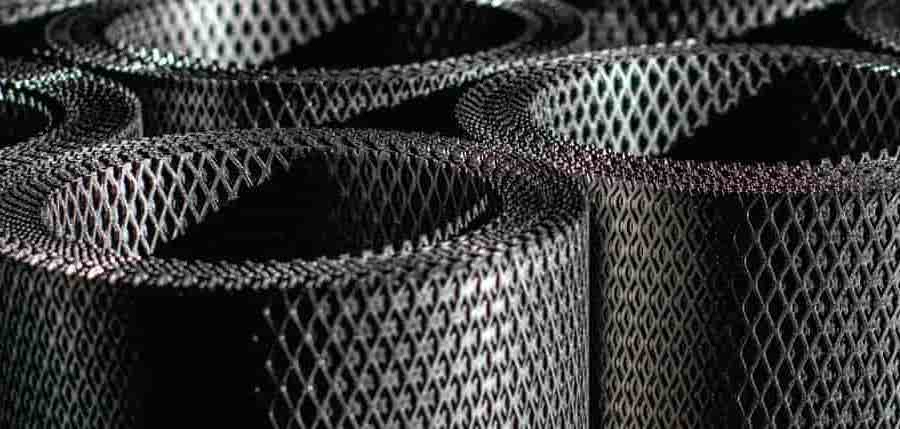

Aluminium perforated metal sheets have become increasingly popular in various industries due to their unique blend of functionality and aesthetic appeal. These sheets are made from high-quality aluminium, which is then processed to create holes of various shapes and sizes. The versatility and lightweight nature of aluminium, combined with the customization options of perforated sheets, make them ideal for a wide array of applications.

One of the most significant advantages of aluminium perforated metal sheets is their exceptional durability. Aluminium is known for its resistance to corrosion, making these sheets suitable for both indoor and outdoor use. Unlike other materials that may degrade when exposed to moisture or harsh weather conditions, aluminium maintains its structural integrity over time. This property makes it an ideal choice for applications ranging from architectural facades to industrial filters.

In addition to their durability, perforated metal sheets are incredibly versatile. They can be used in a variety of fields, including construction, manufacturing, and art. In construction, architects and designers often use perforated aluminium for building facades, ceilings, and partitions. The perforation patterns can be tailored to create stunning visual effects while still allowing for light and air to pass through. This characteristic not only enhances the aesthetic appearance of buildings but also contributes to energy efficiency by reducing the need for artificial lighting.

In the manufacturing sector, aluminium perforated sheets serve practical purposes as well. They are commonly used for safety barriers, noise reduction panels, and filtration systems. The perforations can be designed to provide the necessary strength while allowing for ventilation or liquid flow. For instance, in the automotive industry, these sheets can be used in radiator grilles and engine compartments, where cooling is critical.

aluminium perforated metal sheet

Another significant benefit of using aluminium perforated sheets is their lightweight nature. Compared to steel and other metals, aluminium offers a low weight-to-strength ratio, making transportation and installation easier and more cost-effective. This lightweight quality is especially important in industries where reducing overall weight can lead to enhanced performance, such as aerospace and automotive applications.

Beyond practicality, aluminium perforated metal sheets are also favored for their eco-friendliness

. Aluminium is a recyclable material, and using perforated sheets contributes to sustainability goals. At the end of their lifecycle, these sheets can be recycled and repurposed, reducing waste and the demand for new materials.The design possibilities offered by aluminium perforated metal sheets are virtually limitless. With advanced technology, manufacturers can create intricate patterns and custom hole sizes to meet specific design requirements. This flexibility allows architects and designers to indulge their creativity while ensuring that the sheets meet functional needs.

In conclusion, aluminium perforated metal sheets are an essential element in modern design and manufacturing. Their combination of durability, versatility, lightweight properties, and aesthetic appeal makes them an ideal choice across numerous industries. Whether used in architectural applications, industrial processes, or artistic endeavors, these sheets not only fulfill functional requirements but also enhance overall design. As technology continues to advance, the potential applications for aluminium perforated sheets are bound to expand, further solidifying their place in the market.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.