Aluminium Expanded Mesh Price Understanding the Costs and Factors Influencing Pricing

Aluminium expanded mesh is a versatile material widely used in various applications, including architectural design, safety barriers, filtration, and more. Its popularity can be attributed to its lightweight nature, durability, and aesthetic appeal. However, when considering purchasing aluminium expanded mesh, potential buyers often find themselves pondering its price. Several factors influence the cost of aluminium expanded mesh, and understanding them can help consumers make informed decisions.

1. Material Quality

The quality of the aluminium used plays a crucial role in determining the price. Aluminium is available in different grades, and the higher the grade, the more expensive it tends to be. High-grade aluminium offers better corrosion resistance, strength, and longevity, which can justify a higher price tag. Conversely, lower-quality aluminium may be cheaper but could lead to issues in durability and performance over time.

2. Mesh Specifications

The specifications of the expanded mesh, such as thickness, opening size, and mesh design, significantly impact the price. Thicker materials and smaller openings generally cost more due to the increased material used and the complexity involved in the manufacturing process. Additionally, custom designs or sizes can also lead to higher prices as they often require specialized production techniques.

3. Manufacturing Process

The production method used to create aluminium expanded mesh is another factor that influences pricing. There are various techniques for expanding aluminium, including mechanical expansion and die-casting. Mechanical expansion is the most common method, producing a uniform and consistent product. However, like any manufacturing process, the cost associated with labor, machinery, and technology will affect the overall price.

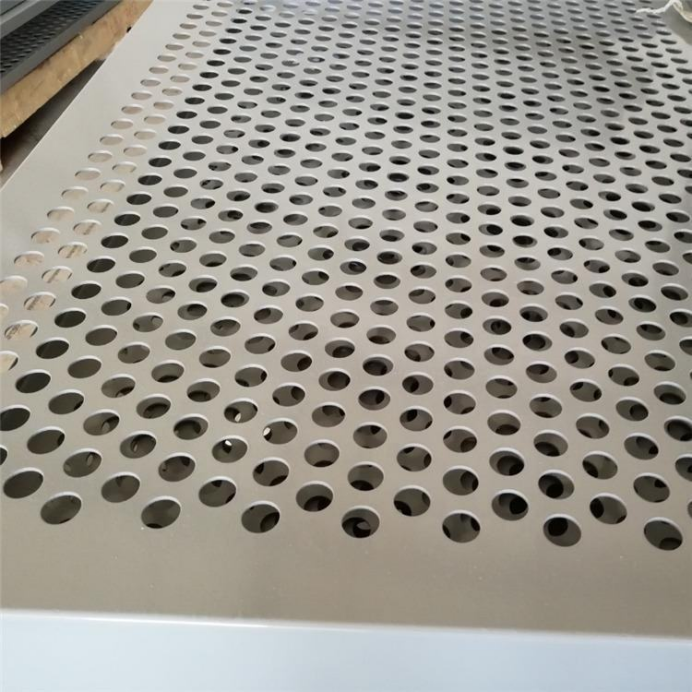

aluminium expanded mesh price

The dynamics of the market play an essential role in determining the price of aluminium expanded mesh. When demand exceeds supply, prices tend to rise due to competitive pressures. Conversely, during periods of low demand, manufacturers may lower prices to attract buyers. Additionally, fluctuations in the global aluminium market—affected by factors such as mining costs, geopolitical events, and trade policies—can directly influence the price of finished products, including expanded mesh.

5. Location and Shipping Costs

Geographical location can also impact pricing. Depending on where the product is sourced from, shipping costs can vary significantly. If the aluminium expanded mesh has to be transported over long distances, these logistics expenses can be added to the final price. For consumers, buying from local suppliers can sometimes lead to savings on shipping while supporting local businesses.

6. Quantity and Bulk Orders

When purchasing aluminium expanded mesh, the quantity required can significantly affect the price per unit. Wholesale rates are typically lower than retail, and buying in bulk can often lead to discounts. For large projects, engaging with suppliers who offer competitive bulk pricing can result in significant cost savings.

Conclusion

Understanding the price of aluminium expanded mesh involves considering various factors, including material quality, specifications, manufacturing processes, market dynamics, and logistical considerations. By doing thorough research and comparing different suppliers and options, potential buyers can ensure they make informed purchasing decisions that align with their budgets and project needs. As this material continues to play an integral role across numerous industries, being aware of its pricing structure empowers consumers to invest wisely in aluminium expanded mesh products that will meet their requirements in both functionality and aesthetics.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.