About AnPing Zhongtai Expanded Metal Mesh Co., Ltd

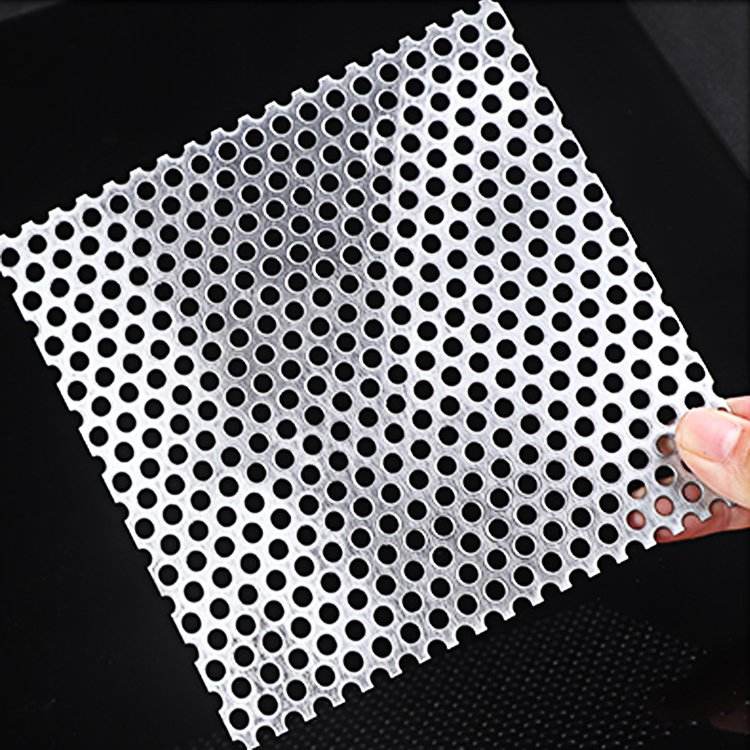

AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer specializing in **3D Galvanized Steel Perforated Metal Sheet** and related industrial solutions. With over a decade of experience, the company has established itself as a trusted supplier for **perforated metal products

Key Features and Technical Specifications

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Dimensions | Thickness: Up to 18 mm | Width: Up to 2000 mm | Length: Up to 6000 mm |

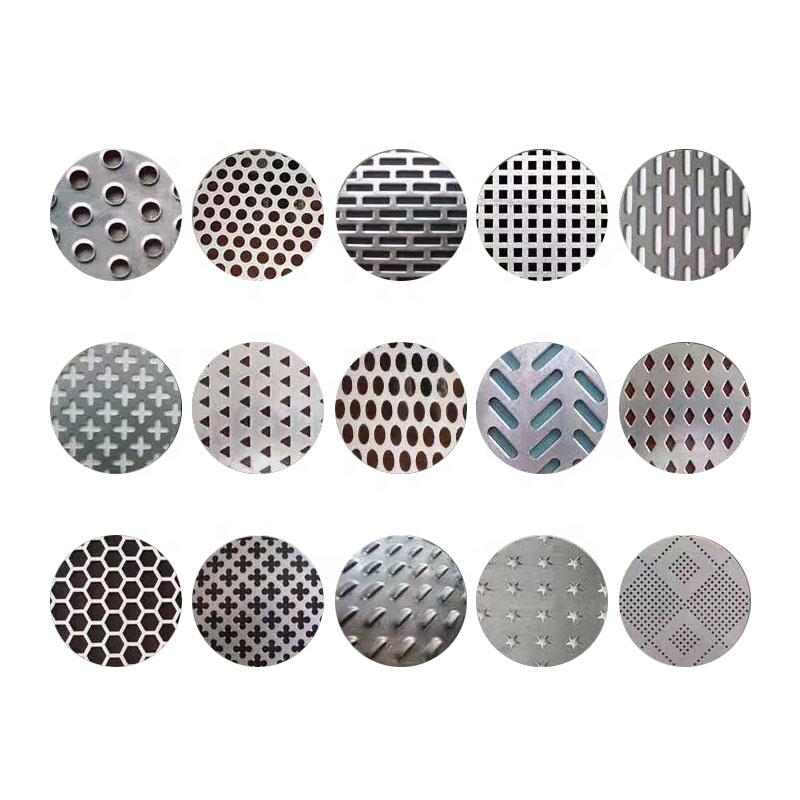

| Perforation Options | Custom designs, full perforation fields, unperforated margins |

| Standard Processes | Straightening, cutting to size, pallet packing |

| Additional Services | Bending, rolling, welding, powder coating, oil cleaning |

Industrial Applications

The **3D Galvanized Steel Perforated Metal Sheet

- Chemical Machinery: Used in filtration systems and reactor components

- Pharmaceutical Equipment: Ensures sterile environments through precise perforation

- Food and Beverage Machines: Meets hygiene standards with corrosion-resistant materials

- Refrigeration Equipment: Enhances airflow efficiency in HVAC systems

- Acoustics: Integrated into soundproofing panels for industrial settings

For detailed application examples, visit the product page.

Technical Advantages

The **3D Galvanized Steel Perforated Metal Sheet

- Structural Integrity: Three-zone hole design (dents, cutting zone, extraction area) ensures durability

- Customization: Full perforation fields and customer-specific designs available

- Corrosion Resistance: Galvanized coating protects against environmental degradation

- Cost Efficiency: Ready-made components reduce post-purchase processing

According to NIST, perforated metal sheets with galvanized coatings demonstrate 30% higher corrosion resistance in industrial environments.

Production Process

The manufacturing process involves:

- Material Preparation: Selection of corrosion-resistant alloys based on application requirements

- Perforation: Three-stage hole creation (dents, cutting, extraction) for optimal structural performance

- Finishing: Straightening, cutting, and packaging for immediate use

- Additional Services: Custom bending, welding, and surface treatments

For technical specifications, refer to the product documentation.

Market Position and Customer Support

As a leader in the **perforated metal industry

- Global Reach: Exporting to over 50 countries

- Quality Assurance: Adherence to ISO 9001 standards

- Technical Support: On-site consultations and design assistance

Visit the company website to explore their full product portfolio.

Conclusion

The **3D Galvanized Steel Perforated Metal Sheet

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.