Introduction

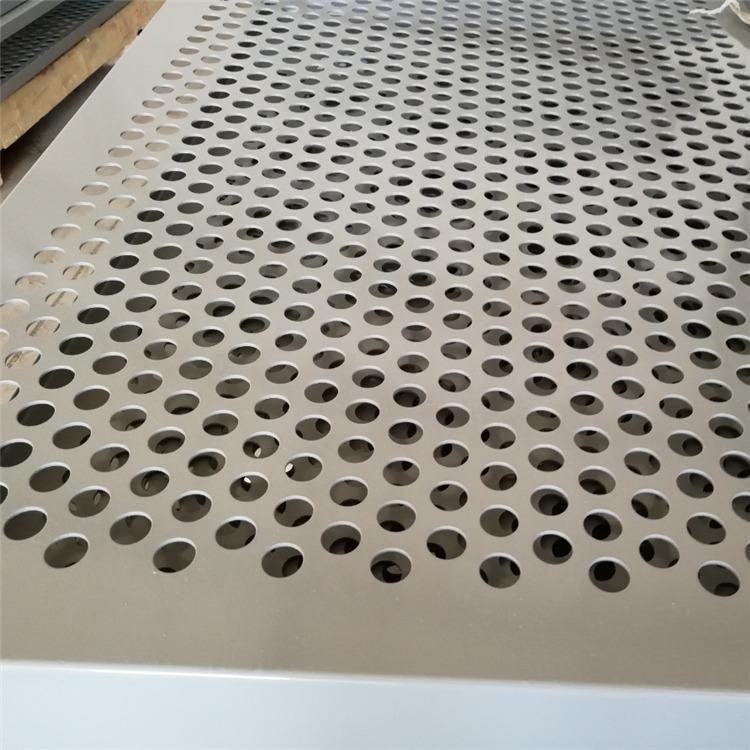

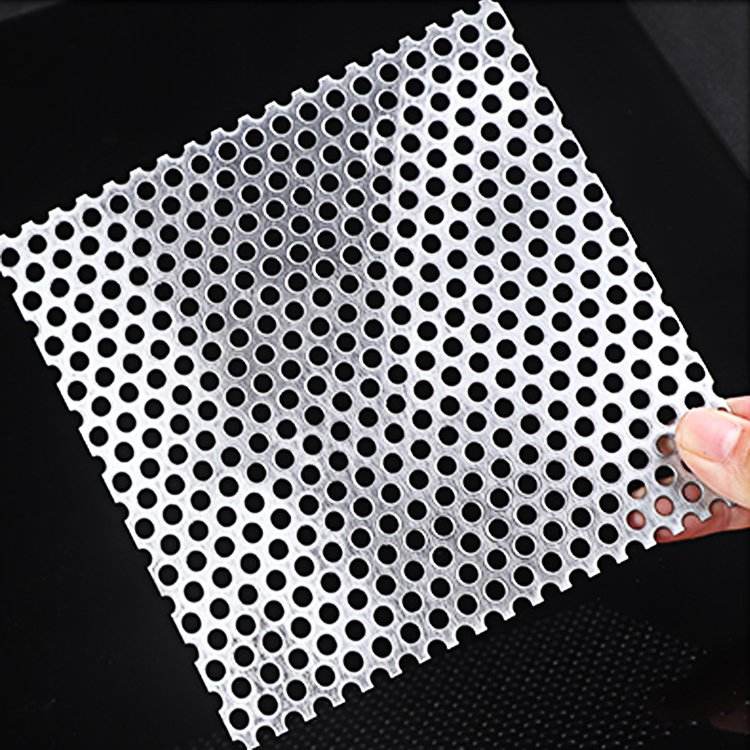

Perforated metal sheets have become a cornerstone in modern industrial applications due to their versatility, durability, and aesthetic appeal. Among these, 3D Galvanized Steel Perforated Metal Sheets stand out for their unique structural design and wide-ranging utility. This article explores the technical specifications, applications, and advantages of these sheets, as well as the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, the leading manufacturer behind this innovation.

Product Structure and Manufacturing Process

The 3D Galvanized Steel Perforated Metal Sheet is engineered with a precise hole structure that enhances its functional performance. During production, the sheet metal undergoes three critical zones:

- Zone of Dents: This area is where the initial deformation occurs, creating the characteristic 3D texture.

- Cutting Zone: Here, the material is precisely cut to form the perforations, ensuring uniformity and accuracy.

- Extraction Area: This stage involves removing the excess material, leaving behind the structured perforations.

Typical sheets are produced with unperforated transverse and longitudinal margins, which provide structural integrity. However, the company offers customization options, including perforation according to customer drawings and full perforation fields, subject to consultation. Post-perforation, sheets are straightened to ensure flatness, and additional processing services such as bending, welding, and powder coating are available to create ready-made components.

Applications in Diverse Industries

The versatility of 3D Galvanized Steel Perforated Metal Sheets makes them indispensable in numerous sectors. Key applications include:

- Chemical Machinery: Used for filtration and ventilation systems due to their corrosion resistance.

- Pharmaceutical Equipment: Ensures hygiene and durability in controlled environments.

- Food and Beverage Machines: Resists wear and tear while maintaining safety standards.

- Refrigeration Equipment: Enhances airflow efficiency in central air conditioning systems.

- Acoustics: Integrated into silencing equipment and speaker enclosures for sound control.

These sheets are also employed in fencing and architectural designs, where their 3D structure provides both aesthetic appeal and structural strength.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Dimensions | Thickness: Up to 18 mm; Width: Up to 2,000 mm; Length: Up to 6,000 mm. Coil width: Up to 1,600 mm for specific perforations. |

| Standard Operations | Single straightening, cutting to size, and pallet packing. |

| Additional Services | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. |

For specialized perforations, thickness and width limitations may apply, and unperforated margins are required for technological processes.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

As a leader in the metal mesh industry, AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a trusted supplier of high-quality perforated metal solutions. With advanced production lines and a commitment to innovation, the company specializes in creating customized metal sheets that meet the unique demands of global industries. Their state-of-the-art facilities, including the 1.ll-round 360 production line, ensure precision and efficiency in manufacturing. Additionally, the use of KASRY Nesting programming systems and AUTOCAD-based software enhances operational accuracy, reducing waste and improving productivity.

The company's dedication to quality is reflected in its comprehensive post-processing services, which transform raw sheets into ready-to-use components. This end-to-end approach ensures that clients receive products that are not only durable but also tailored to their specific needs.

Why Choose 3D Galvanized Steel Perforated Sheets?

The 3D Galvanized Steel Perforated Metal Sheet offers several advantages:

- Enhanced Structural Integrity: The 3D design provides superior strength compared to traditional flat sheets.

- Corrosion Resistance: Galvanization ensures longevity in harsh environments.

- Customizability: Tailored perforation patterns and dimensions to suit specific applications.

- Cost-Effectiveness: Reduces the need for additional components through integrated processing services.

These features make the product an ideal choice for industries requiring both functionality and durability.

Expertise and Standards

The development of 3D Galvanized Steel Perforated Metal Sheets aligns with industry standards for precision and performance. According to the National Institute of Standards and Technology (NIST), "Precise measurements and research are critical for advancing technology and ensuring quality in manufacturing processes." AnPing Zhongtai's adherence to rigorous standards ensures that their products meet the exacting requirements of global markets.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet exemplifies the fusion of innovation and practicality in industrial design. With its robust structure, customizable options, and wide-ranging applications, this product is a testament to the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd. As industries continue to demand more efficient and durable solutions, the company's commitment to quality and innovation ensures they remain at the forefront of the metal mesh market.

References

National Institute of Standards and Technology (NIST) - "Driving Innovation: From developing precise atomic clocks to creating encryption standards to supporting manufacturing, NIST plays a crucial role in advancing technology." [https://www.nist.gov/]

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.