When it comes to modern fencing solutions, 3D galvanized steel perforated metal sheets have emerged as a versatile and durable option. These sheets combine advanced manufacturing techniques with robust material properties to meet diverse industrial and architectural needs. This article delves into the technical specifications, applications, and unique advantages of this product, while also exploring the company behind its creation, AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

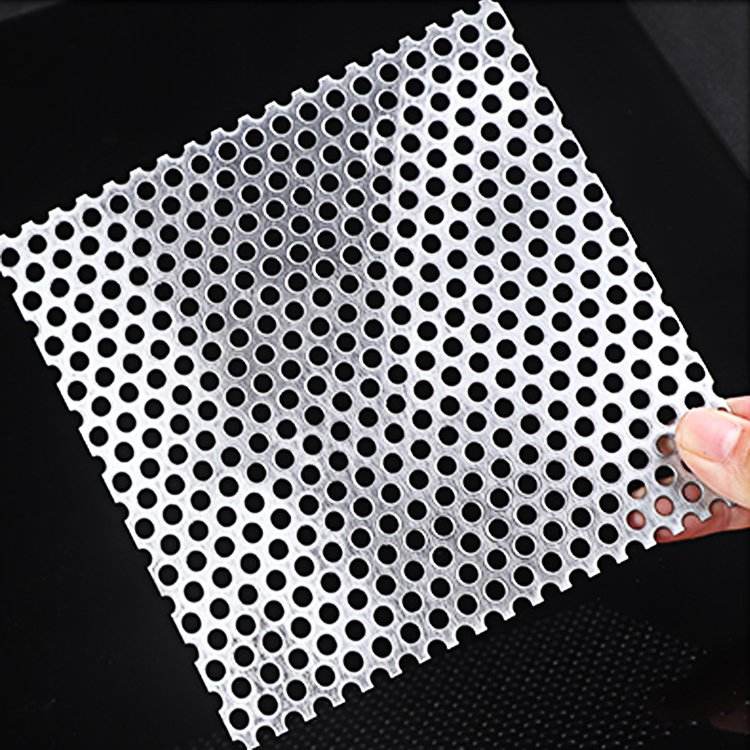

Understanding the Structure of Perforated Holes

The perforation process of these steel sheets is a critical aspect of their design. The holes are created through a multi-stage production process that involves three distinct zones:

- Zone of Dents: This area is formed during the initial stamping phase, where the metal sheet is pressed to create the basic shape of the holes.

- cutting Zone: Here, the material is precisely cut to define the edges of the perforations, ensuring dimensional accuracy.

- Extraction Area: This stage involves removing the excess material from the holes, leaving behind the structured pattern.

These zones work in harmony to produce a consistent and high-quality perforation pattern. The standard production process also includes unperforated margins along the transverse and longitudinal edges of the sheets, which provide structural integrity and facilitate handling during installation.

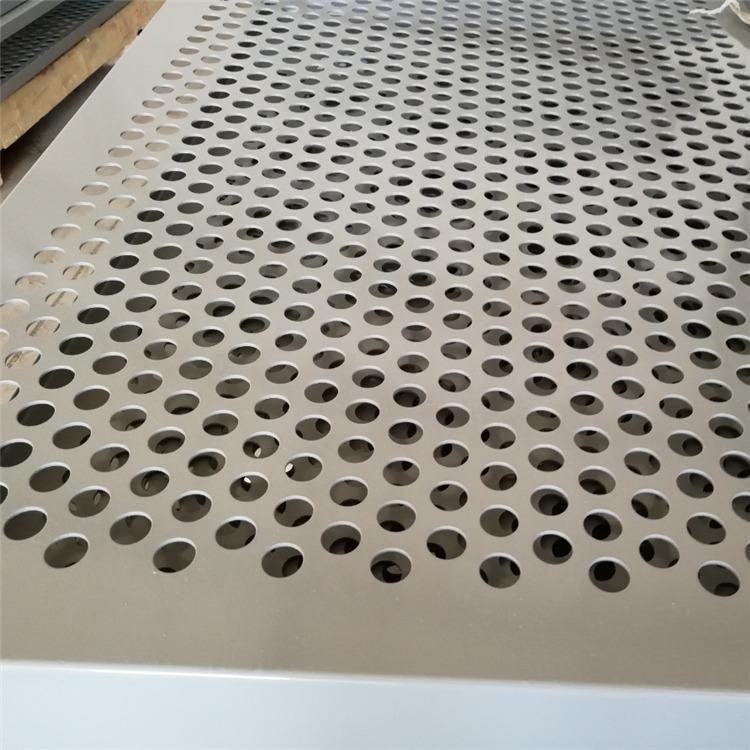

Technical Specifications and Customization Options

The 3D galvanized steel perforated metal sheet is available in a wide range of materials and dimensions to suit various applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant steel, heat-resistant steel, stainless steel, acid-resistant steel, aluminum, copper, brass, bronze, plastics, and rubbers. |

| Thickness | Up to 18 mm. |

| Width | Up to 2,000 mm. |

| Length | Up to 6,000 mm. |

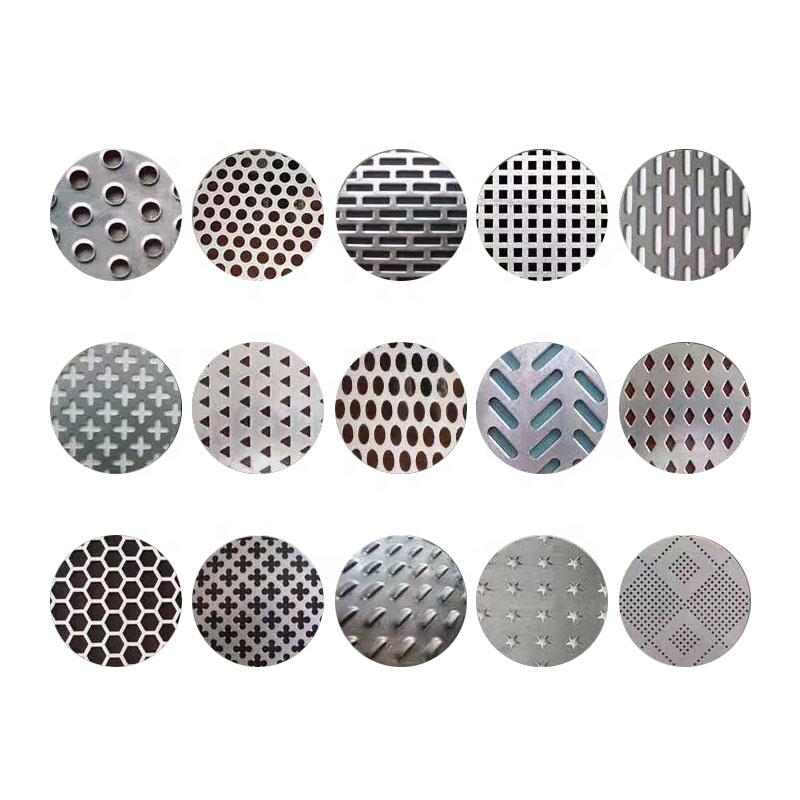

| Perforation Options | Standard sheets have unperforated margins, but custom perforation based on customer drawings is possible. Full perforation fields are available after consultation. |

Additional processing services are offered to enhance the product's functionality. These include bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. Such services ensure that the sheets can be tailored to specific project requirements, reducing the need for secondary manufacturing steps.

Applications Across Industries

The versatility of 3D galvanized steel perforated metal sheets makes them suitable for a broad range of applications. Some of the key industries that benefit from this product include:

- Chemical Machinery: Used in filtration systems and equipment that require corrosion resistance and durability.

- Pharmaceutical Equipment: Ideal for environments where hygiene and material resistance to chemicals are critical.

- Food and Beverage Machines: The perforated design allows for efficient drainage and ventilation.

- Harvesters and Dry-Cleaning Machines: The sheets provide structural support while allowing for the passage of materials.

- Refrigeration Equipment: Used in central air conditioning systems for heat exchange and airflow management.

- Acoustic Equipment: The perforations help in sound absorption and diffusion.

These applications highlight the product's adaptability to different environments, from industrial settings to consumer goods. The galvanized coating further enhances its resistance to rust and corrosion, making it ideal for outdoor and high-moisture environments.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded in AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this company has established itself as a leader in the production of metal mesh and perforated sheets. With a focus on innovation and quality, the company offers a wide range of products tailored to meet the demands of global markets.

One of the key strengths of AnPing Zhongtai is its advanced manufacturing capabilities. The company utilizes state-of-the-art machinery, including a ll-round 360 production line cutting group, which enables automated tube feeding, cutting, and transmission operations. This ensures high precision and efficiency in production. Additionally, the company employs the KASRY Nesting programming system, which integrates with AutoCAD to streamline the design and programming process.

The company's commitment to quality is further evidenced by its adherence to international standards. As noted by the National Institute of Standards and Technology (NIST), "Precision and consistency in manufacturing are critical for ensuring the reliability of industrial materials. Standards such as those developed by NIST help companies like AnPing Zhongtai maintain the highest levels of quality control and performance" (NIST, 2025).

Advantages of 3D Galvanized Steel Perforated Metal Sheets

Several factors contribute to the popularity of 3D galvanized steel perforated metal sheets:

- Durability: The galvanized coating provides excellent protection against rust and corrosion, ensuring a long service life even in harsh environments.

- Strength: The 3D structure of the perforations enhances the mechanical strength of the sheets, making them suitable for load-bearing applications.

- Customization: The ability to create custom perforation patterns and dimensions allows for tailored solutions to specific project needs.

- Cost-Effectiveness: The availability of pre-processed sheets reduces the need for additional manufacturing steps, lowering overall costs.

- Environmental Benefits: The recyclability of steel and the use of galvanized coatings contribute to sustainable manufacturing practices.

Conclusion: A Reliable Solution for Modern Applications

The 3D galvanized steel perforated metal sheet represents a significant advancement in metal fabrication technology. Its combination of durability, customization, and versatility makes it an ideal choice for a wide range of industries. With the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product continues to set new standards in quality and performance.

As highlighted by the National Institute of Standards and Technology (NIST), "The integration of advanced manufacturing techniques with high-quality materials is essential for meeting the evolving demands of modern industries. Companies that prioritize innovation and precision, like AnPing Zhongtai, play a vital role in driving technological progress" (NIST, 2025).

References

National Institute of Standards and Technology (NIST). (2025). *Advancing Technology Through Precision and Innovation*. Retrieved from https://www.nist.gov.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.