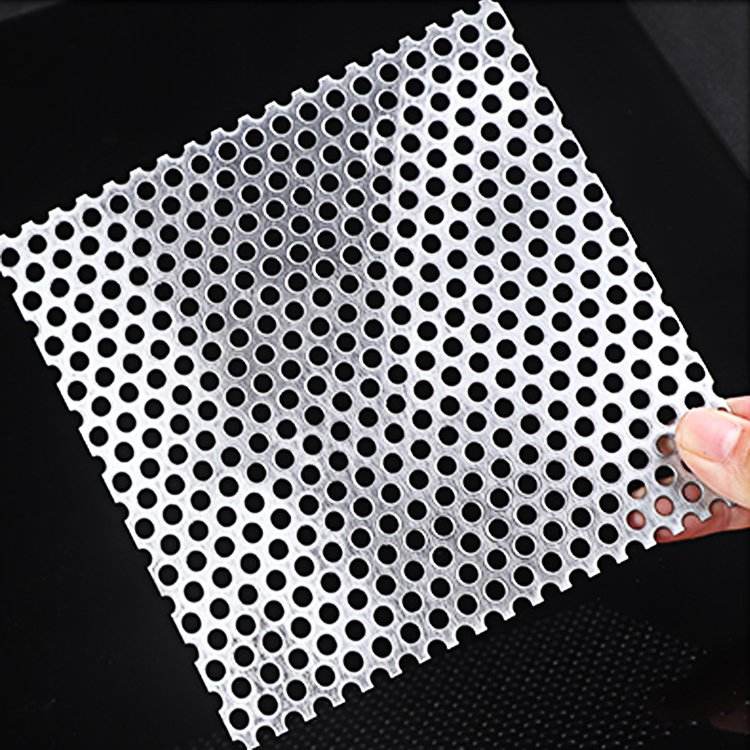

The 3D Galvanized Steel Perforated Metal Sheet represents a cutting-edge innovation in the field of industrial materials, offering a unique combination of structural integrity, durability, and adaptability. Designed for applications ranging from fencing to advanced filtration systems, this product exemplifies the synergy between engineering precision and industrial versatility. This article delves into its core functionalities, technical specifications, and the company behind its production, AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Product Functionality and Design

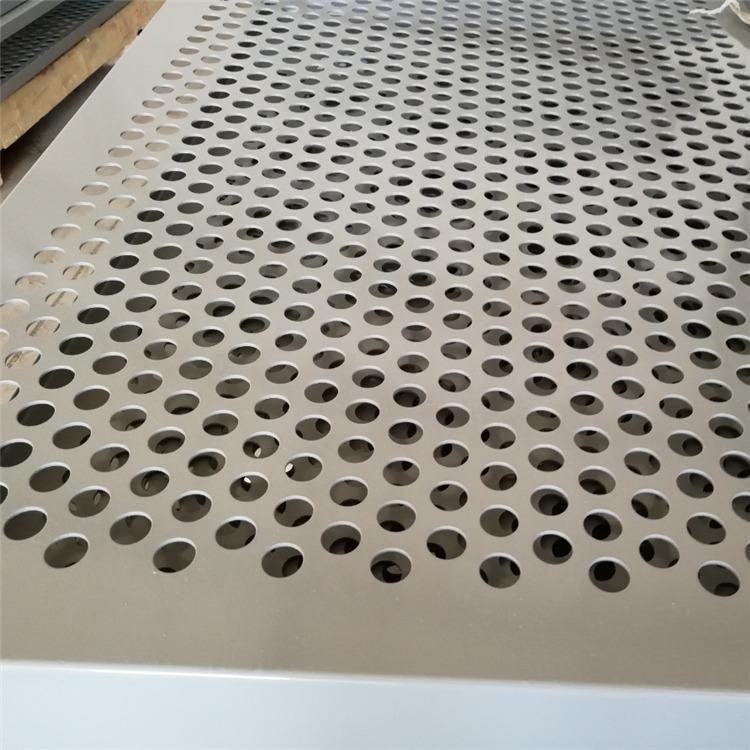

The 3D Galvanized Steel Perforated Metal Sheet is engineered with a sophisticated hole structure that enhances its mechanical and functional properties. During the production process, the sheet metal undergoes three critical zones: the Zone of Dents, Cutting Zone, and Extraction Area. These zones work in harmony to create a uniform perforation pattern that ensures optimal load distribution and structural resilience. The product’s design allows for both standard and customized perforation configurations, catering to a wide array of industrial needs.

Typical sheets are produced with unperforated transverse and longitudinal margins, which provide a stable base for further processing. However, the company also offers the flexibility to create sheets with full perforation fields or those tailored to customer-specific drawings. This adaptability is further enhanced by post-perforation services such as straightening, cutting to size, and packaging, enabling customers to receive ready-made components that align with their project requirements.

Technical Specifications

The 3D Galvanized Steel Perforated Metal Sheet is available in a diverse range of materials and dimensions, making it suitable for both standard and specialized applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant steel, heat-resistant steel, stainless steel, acid-resistant steel, aluminum, copper, brass, bronze, plastics, and rubbers. |

| Dimensions | Thickness: Up to 18 mm; Width: Up to 2,000 mm; Length: Up to 6,000 mm. Coils can be perforated with a width of up to 1,600 mm. |

| Standard Operations | Single straightening, cutting to size, and pallet packaging. |

| Additional Services | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil wiping/cleaning. |

The product’s versatility is further amplified by its ability to accommodate custom perforation patterns, though certain restrictions may apply to thickness, width, and the inclusion of unperforated margins for technological purposes.

Applications in Diverse Industries

The 3D Galvanized Steel Perforated Metal Sheet is a cornerstone in multiple industrial sectors due to its robustness and adaptability. Key applications include:

- Chemical Machinery: Used in reactors and storage tanks for its corrosion resistance and durability.

- Pharmaceutical Equipment: Ensures hygienic and precise filtration in drug manufacturing processes.

- Food and Beverage Machinery: Ideal for conveyor systems and processing equipment that require frequent cleaning.

- Filtration Systems: Its uniform perforation pattern enhances efficiency in air and liquid filtration.

- Acoustics: Employed in silencing equipment to reduce noise pollution in industrial environments.

- Construction: Utilized in fencing and structural components for its strength and aesthetic appeal.

According to NIST (National Institute of Standards and Technology), the integration of advanced materials like perforated metals into industrial systems significantly improves operational efficiency and safety standards. This aligns with the 3D Galvanized Steel Perforated Metal Sheet’s role in modern manufacturing, where precision and reliability are paramount.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded in Anping County, Hebei Province, AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a leader in the production of high-quality metal mesh and perforated sheets. The company’s commitment to innovation and customer-centric solutions has enabled it to serve a global clientele across various industries.

With a focus on precision engineering and customization, AnPing Zhongtai leverages advanced technologies such as the KASRY Nesting Programming System to optimize production workflows. This system, integrated with AUTOCAD, allows for intuitive and efficient design, reducing lead times and enhancing product accuracy. The company’s state-of-the-art facilities ensure compliance with international standards, including those outlined by NIST in its guidelines for industrial material specifications.

Furthermore, AnPing Zhongtai offers a comprehensive suite of post-production services, including bending, welding, and powder coating, to meet the unique requirements of its clients. This holistic approach not only streamlines the supply chain but also ensures that customers receive products that are ready for immediate deployment.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet stands as a testament to the advancements in industrial material science, combining durability, adaptability, and precision. Its wide-ranging applications and technical versatility make it an indispensable asset for industries seeking reliable and efficient solutions. Backed by the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product exemplifies the intersection of innovation and practicality in modern manufacturing.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.