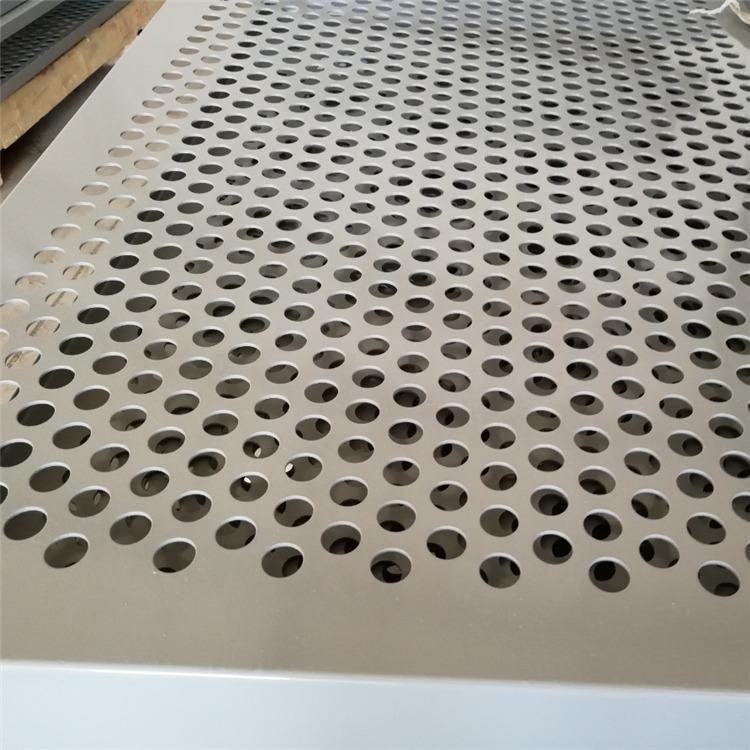

Discover the versatility and durability of 3D Galvanized Steel Perforated Metal Sheets, engineered to meet the demands of modern industrial applications. Developed by AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product combines advanced manufacturing techniques with high-quality materials to deliver exceptional performance across diverse sectors.

Understanding the Structure and Production Process

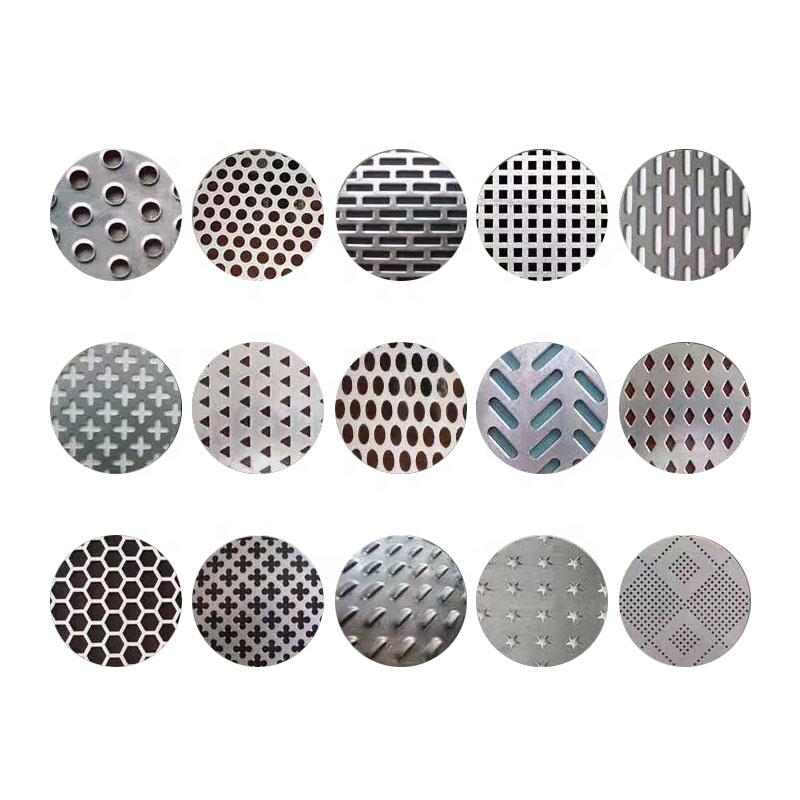

The 3D Galvanized Steel Perforated Metal Sheet is crafted through a meticulous production process that ensures precision and durability. The hole structure consists of three critical zones:

- Zone of Dents: This area forms during the initial stages of perforation, creating a textured surface that enhances structural integrity.

- Cutting Zone: Here, the material is precisely cut to achieve the desired pattern and dimensions.

- Extraction Area: This zone facilitates the removal of excess material, ensuring a clean and accurate final product.

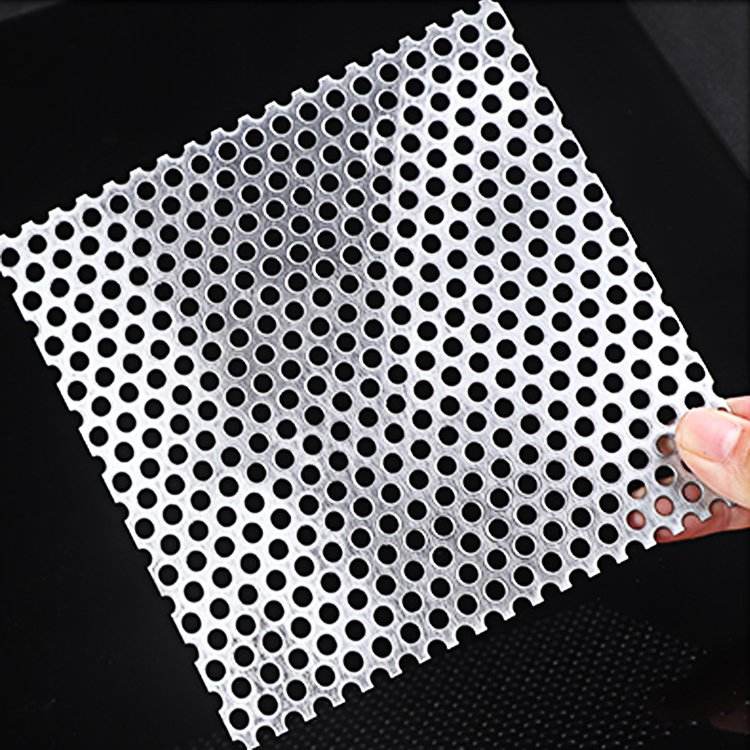

Typical sheets feature unperforated margins in both transverse and longitudinal directions. However, the company offers customization options, allowing customers to specify unique designs or full perforation fields. Standard post-processing includes straightening, cutting, and palletizing, with additional services like bending, welding, and powder coating available upon request.

Technical Specifications and Material Options

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Dimensions | Thickness up to 18 mm, width up to 2,000 mm, length up to 6,000 mm |

| Standard Operations | Single straightening, cutting to size, packing on pallets |

| Additional Services | Bending, rolling, pressing, trapezoidal, framing, welding, powder coating, oil cleaning |

Applications Across Industries

The 3D Galvanized Steel Perforated Metal Sheet is a versatile solution with applications spanning multiple sectors:

- Chemical Machinery: Ideal for filtration systems and ventilation components.

- Pharmaceutical Equipment: Ensures hygiene and precision in manufacturing processes.

- Food and Beverage Machines: Resists corrosion and maintains structural integrity in high-moisture environments.

- Refrigeration Equipment: Enhances airflow and heat exchange efficiency.

- Acoustics and Silencing Equipment: Reduces noise pollution in industrial settings.

- Hydraulic Fittings and Papermaking Machinery: Provides durability under high-pressure conditions.

As noted by the National Institute of Standards and Technology (NIST), "Precision in material design is critical for industrial applications, ensuring both functional performance and longevity." This aligns with the AnPing Zhongtai Expanded Metal Mesh Co., Ltd commitment to quality and innovation.

Company Background and Expertise

Founded in AnPing Zhongtai Expanded Metal Mesh Co., Ltd, the company has established itself as a leader in metal perforation technology. With over two decades of experience, they specialize in custom solutions tailored to client needs. Their state-of-the-art facilities, including a 360-degree production line, ensure efficient and accurate manufacturing.

The company's KASRY Nesting programming system streamlines operations, enabling automated tube feeding, cutting, and transmission. This technology not only enhances productivity but also reduces waste, making it a sustainable choice for industries prioritizing efficiency.

Why Choose 3D Galvanized Steel Perforated Sheets?

Several key advantages position this product as a preferred choice:

- Enhanced Durability: Galvanization provides a protective zinc coating, preventing rust and extending the product's lifespan.

- Customization Flexibility: From hole patterns to material types, the company offers extensive customization options.

- Cost-Effectiveness: Pre-cut and pre-processed sheets reduce the need for additional manufacturing steps, saving time and resources.

- Environmental Compliance: The production process adheres to strict environmental standards, ensuring minimal ecological impact.

According to NIST, "Standardized manufacturing processes are essential for maintaining consistency and quality in industrial materials." This principle is reflected in the company's adherence to rigorous quality control measures.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet exemplifies the synergy between advanced technology and industrial needs. With its robust construction, versatile applications, and commitment to innovation, it stands as a reliable solution for modern manufacturing challenges. Partnering with AnPing Zhongtai Expanded Metal Mesh Co., Ltd ensures access to cutting-edge products and expert support, driving success in diverse industries.

References

National Institute of Standards and Technology (NIST). "Driving Innovation in Technology and Industry." Retrieved from https://www.nist.gov.

AnPing Zhongtai Expanded Metal Mesh Co., Ltd. "3D Galvanized Steel Perforated Metal Sheet." Retrieved from https://www.ztwiremesh.com.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.