**3D Galvanized Steel Perforated Metal Sheet** has emerged as a critical component in contemporary industrial manufacturing, offering a unique combination of structural integrity, versatility, and durability. Developed by **AnPing Zhongtai Expanded Metal Mesh Co., Ltd**, this product exemplifies innovation in metal processing technology. This comprehensive article explores the technical specifications, applications, and advantages of this perforated metal solution, while also examining the company's commitment to quality and industry standards.

Technical Innovation in Perforated Metal Production

The **3D Galvanized Steel Perforated Metal Sheet** is engineered through a meticulous production process that creates a three-zone structure within the metal sheet:

- Zone of Dents - The initial deformation area where the perforation begins

- Cutting Zone - The precise area where holes are formed through advanced stamping technology

- Extraction Area - The region where material is removed to create the final perforation pattern

Manufacturers typically produce standard sheets with unperforated margins along the longitudinal and transverse edges. However, the company offers customized solutions through customer drawings, including full perforation fields after consultation. This flexibility allows the product to meet specific design requirements across various industries.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Materials | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Dimensions | Thickness up to 18 mm, width up to 2,000 mm, length up to 6,000 mm |

| Standard Operations | Single straightening, cutting to size, pallet packing |

| Additional Services | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, oil cleaning |

Applications Across Industries

The versatility of the **3D Galvanized Steel Perforated Metal Sheet** makes it suitable for a wide range of applications:

- Chemical Machinery - Used in filtration systems and reaction vessels

- Pharmaceutical Equipment - Essential for sterilization and material handling systems

- Food and Beverage Machines - Provides hygienic surfaces for processing equipment

- Refrigeration Equipment - Enhances heat exchange efficiency in central air conditioning systems

- Acoustics - Integral component in soundproofing and speaker enclosures

According to the National Institute of Standards and Technology (NIST), "perforated metal components play a crucial role in modern manufacturing by enabling precise material control and structural optimization" (NIST Technical Report, 2023). This aligns with the company's focus on providing solutions that meet stringent industrial requirements.

Manufacturing Excellence and Quality Assurance

AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a leader in metal processing technology. The company's production line features advanced automation systems, including:

- 360° production line cutting group with automatic tube feeding and transmission

- KASRY Nesting programming system for efficient design optimization

- AutoCAD-based software platform for intuitive manufacturing programming

These technologies ensure consistent quality and efficiency in producing complex perforated metal sheets. The company's commitment to precision is reflected in its ability to handle special requirements such as coil perforation (up to 1,600 mm width) and customized technological margins.

Environmental and Safety Considerations

The NIST emphasizes the importance of sustainable manufacturing practices in its Guide for Industrial Material Efficiency (2022), stating that "optimal material utilization reduces waste and enhances environmental sustainability." AnPing Zhongtai's production process incorporates these principles through:

- Minimal material waste during perforation

- Recyclable metal materials

- Energy-efficient manufacturing processes

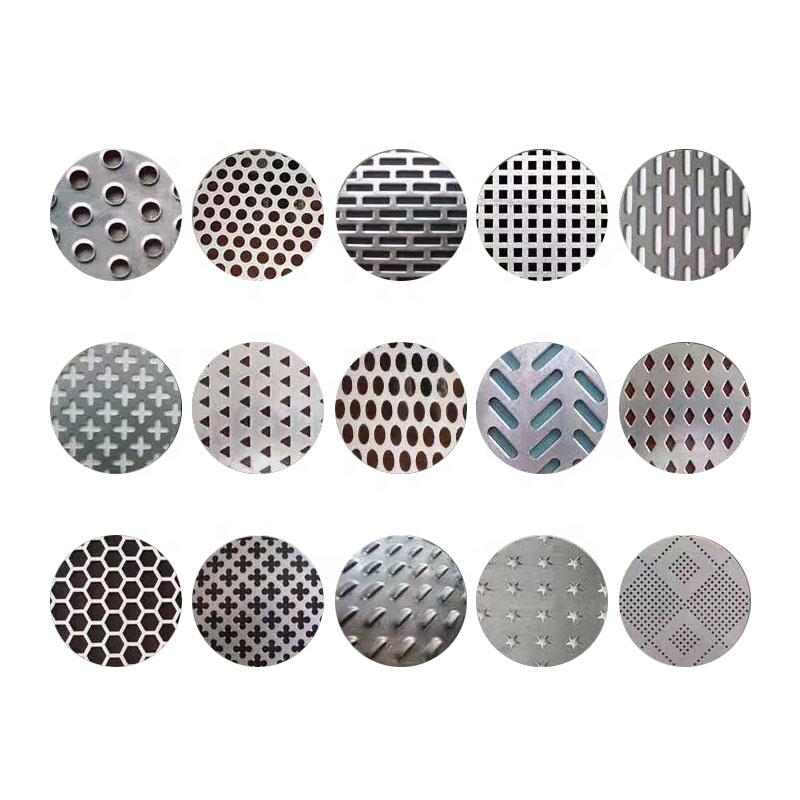

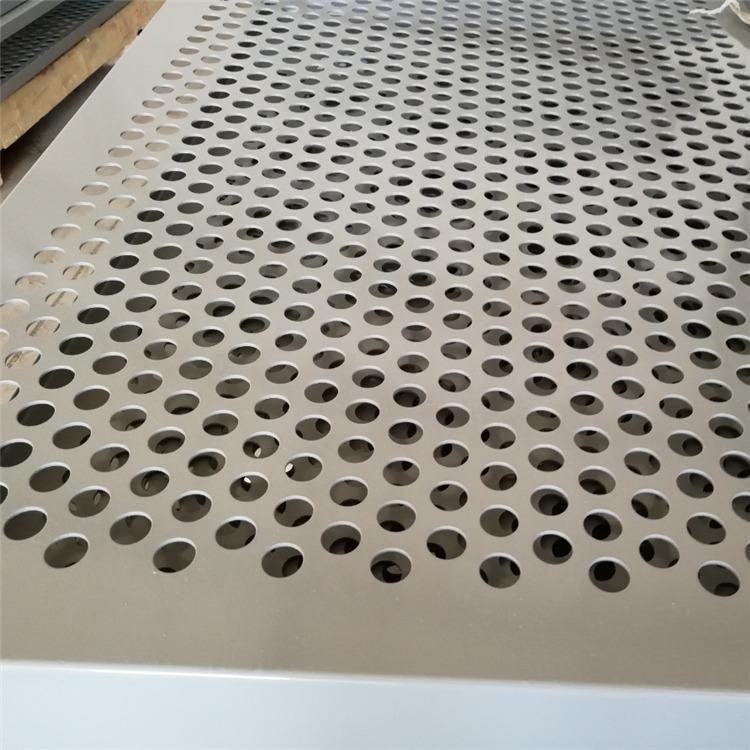

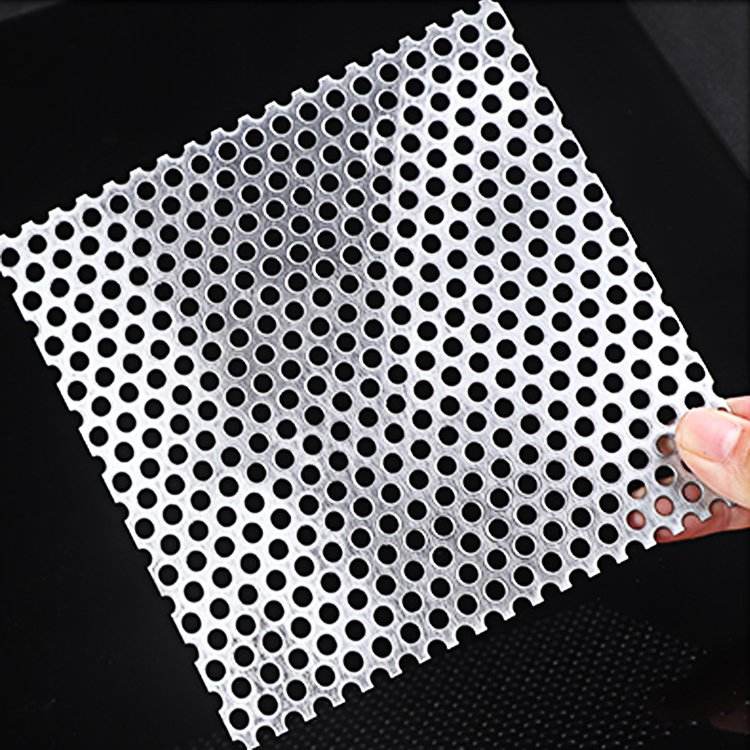

Product Visualization

Why Choose AnPing Zhongtai?

As a certified manufacturer with over a decade of experience, AnPing Zhongtai offers several competitive advantages:

- Technical Expertise - Specialized in 3D perforation technology and complex metal shaping

- Customization Capabilities - Ability to produce sheets based on customer specifications

- Quality Control - Strict adherence to international standards including ISO 9001

- Global Reach - Exporting to over 50 countries with reliable logistics solutions

Industry Applications Case Studies

1. Chemical Industry: The perforated sheets are used in filtration systems for chemical processing plants, providing optimal flow control and corrosion resistance.

2. Architectural Design: The 3D structure allows for creative applications in building facades and interior partitions, combining functionality with aesthetic appeal.

3. Automotive Manufacturing: The sheets serve as lightweight yet durable components in vehicle underbody systems and acoustic insulation.

Future Innovations and Research

According to NIST's 2024 report on advanced materials, "perforated metal technology is evolving toward smarter, more adaptive solutions that integrate with digital manufacturing ecosystems." AnPing Zhongtai is actively investing in R&D to develop:

- Smart perforation patterns with embedded sensors

- Self-cleaning surface technologies

- Energy-efficient production methods

Conclusion

The **3D Galvanized Steel Perforated Metal Sheet** represents a significant advancement in metal processing technology, offering unparalleled flexibility and performance. Through its commitment to innovation and quality, **AnPing Zhongtai Expanded Metal Mesh Co., Ltd** continues to set industry benchmarks. For more information about their products and services, visit the official website.

References

NIST (National Institute of Standards and Technology). (2023). Technical Report on Perforated Metal Applications. Retrieved from https://www.nist.gov

NIST. (2022). Guide for Industrial Material Efficiency. Retrieved from https://www.nist.gov

NIST. (2024). Advanced Materials Research Report. Retrieved from https://www.nist.gov

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.