The 3D Galvanized Steel Material Perforated Metal Sheet is a versatile and durable solution designed for a wide range of industrial and commercial applications. This product combines advanced manufacturing techniques with high-quality materials to deliver exceptional performance and reliability. Below, we explore its features, advantages, technical specifications, applications, and the company behind it.

Product Overview

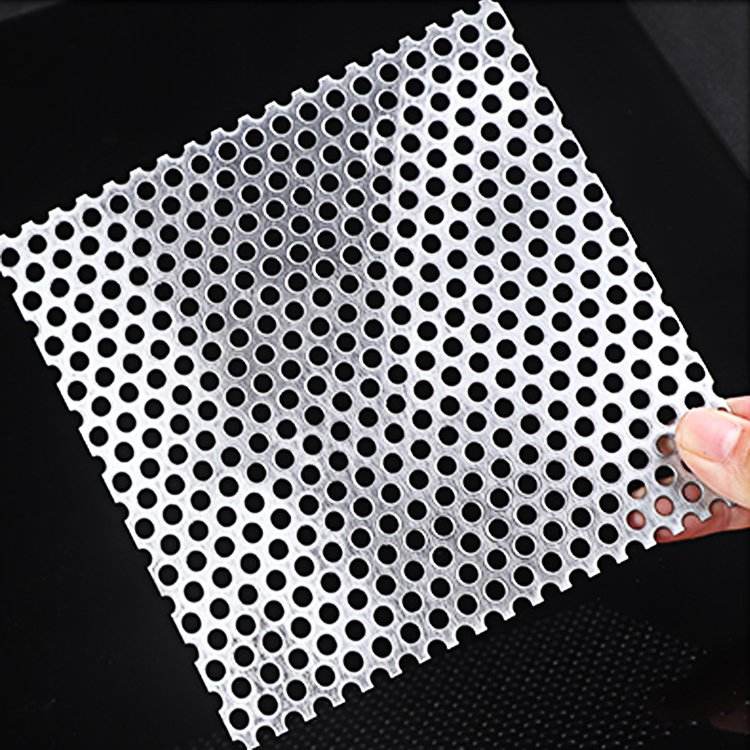

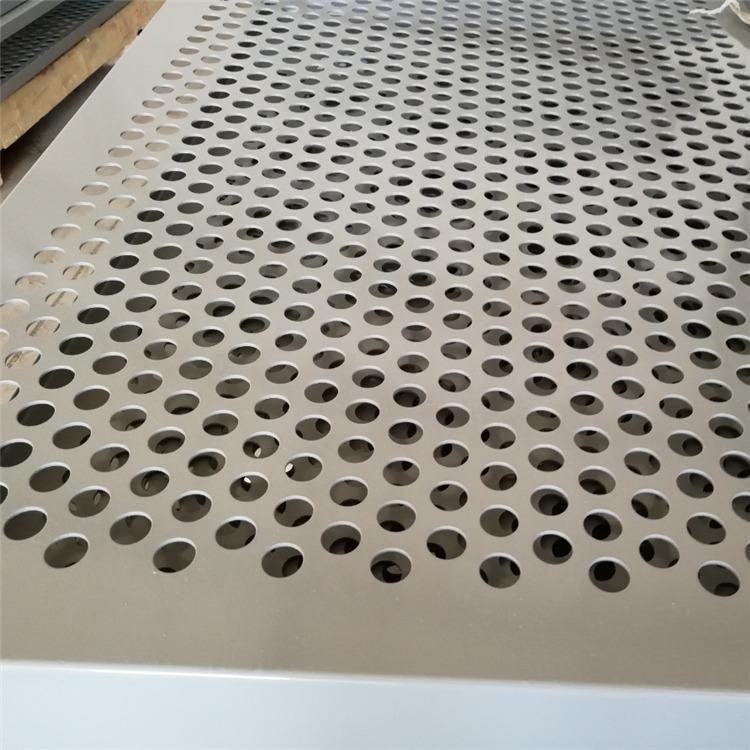

The 3D Galvanized Steel Material Perforated Metal Sheet is engineered to meet the demands of modern industrial environments. Its unique design allows for optimal strength, durability, and adaptability. The sheet is manufactured using a precise process that ensures uniformity in the perforation pattern, making it suitable for both functional and aesthetic purposes.

Key Features

- 3D Structure: The sheet features a three-dimensional hole structure, which enhances its load-bearing capacity and resistance to deformation.

- Galvanized Coating: A protective galvanized layer prevents corrosion, extending the product's lifespan even in harsh environments.

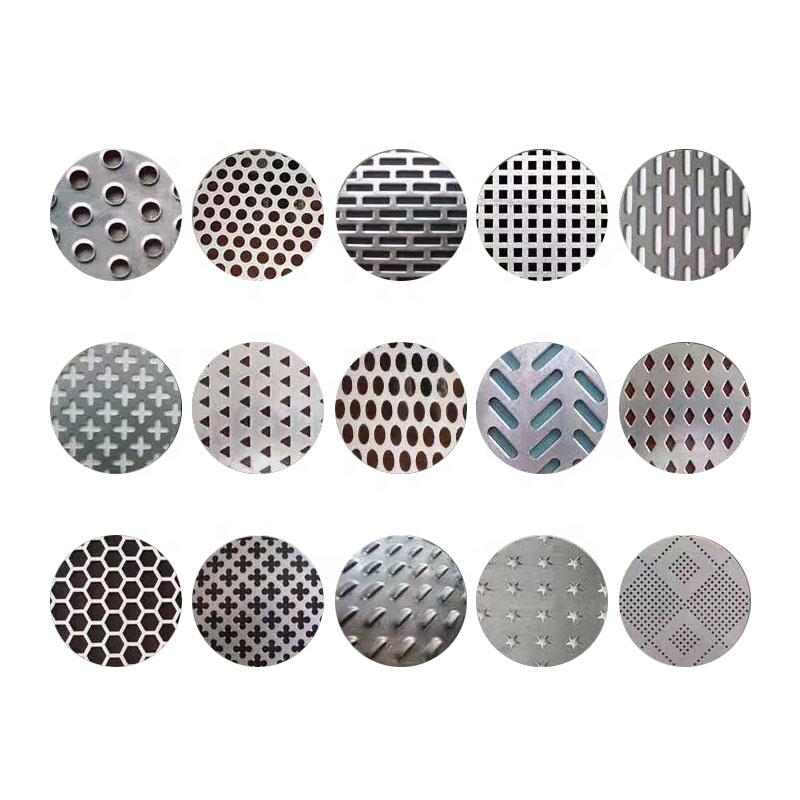

- Customizable Perforation: The product can be tailored to meet specific design requirements, including unique hole patterns and sizes.

- High Strength-to-Weight Ratio: Despite its lightweight, the sheet maintains exceptional structural integrity.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Format | Thickness up to 18 mm, width up to 2,000 mm, length up to 6,000 mm. Coil width up to 1,600 mm for some assortments. |

| Standard Operations | Single straightening, cutting to size, and packing on pallets. |

| Additional Operations | Bending, rolling, pressing, trapezoidal, framing, welding, powder coating, wiping/cleaning with oil. |

Applications

The 3D Galvanized Steel Material Perforated Metal Sheet is widely used across various industries due to its versatility and durability. Some of the key applications include:

- Chemical Machinery: Used in filtration systems and equipment where corrosion resistance is critical.

- Pharmaceutical Equipment: Ideal for components requiring a clean and hygienic surface.

- Food and Beverage Machines: Ensures compliance with food safety standards.

- Refrigeration Equipment: Enhances airflow and heat exchange efficiency.

- Acoustic Panels: Provides sound-dampening properties in industrial and commercial spaces.

- Architectural Applications: Used in facades, partitions, and decorative elements.

Advantages

The 3D Galvanized Steel Material Perforated Metal Sheet offers several advantages that make it a preferred choice in various sectors:

- Enhanced Durability: The galvanized coating and robust material ensure long-term performance in challenging conditions.

- Customization: The ability to create unique perforation patterns allows for tailored solutions to specific needs.

- Cost-Effective: The product's longevity and low maintenance requirements reduce long-term costs.

- Environmental Resistance: Resists corrosion, UV exposure, and extreme temperatures.

- Easy Installation: Pre-cut and pre-treated sheets simplify the installation process.

Company Background

The AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer of perforated metal products, specializing in high-quality steel and metal sheets. With years of experience in the industry, the company has established itself as a reliable supplier for both domestic and international clients. Their commitment to innovation, quality control, and customer satisfaction ensures that their products meet the highest standards.

Manufacturing Process

The production of the 3D Galvanized Steel Material Perforated Metal Sheet involves a meticulous process that ensures precision and consistency. The key steps include:

- Material Selection: High-quality steel is chosen based on the intended application and environmental conditions.

- Perforation: The sheet is perforated using advanced machinery to create the desired pattern. The process includes three zones: the zone of dents, cutting zone, and extraction area.

- Galvanization: A protective zinc coating is applied to enhance corrosion resistance.

- Finishing: The sheet is straightened, cut to size, and packed for shipment. Additional services include bending, welding, and powder coating.

Case Studies and Real-World Applications

The 3D Galvanized Steel Material Perforated Metal Sheet has been successfully implemented in numerous projects across different industries. For example, in the National Institute of Standards and Technology (NIST) (NIST) facilities, perforated metal sheets are used in HVAC systems to improve air circulation and energy efficiency. According to NIST research, such materials play a crucial role in optimizing industrial processes and reducing energy consumption [1].

Conclusion

The 3D Galvanized Steel Material Perforated Metal Sheet is a testament to the advancements in metal fabrication technology. Its combination of durability, customization, and versatility makes it an ideal choice for a wide range of applications. Whether used in industrial machinery, architectural designs, or environmental systems, this product continues to set benchmarks in the industry. For more information, visit the AnPing Zhongtai Expanded Metal Mesh Co., Ltd website to explore their comprehensive product range and services.

Product Images

References

[1] National Institute of Standards and Technology (NIST). (2025). *Research on Industrial Materials and Energy Efficiency*. Retrieved from https://www.nist.gov

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.