Understanding 3 8% Perforated Steel Plate Applications and Benefits

Perforated steel plates have gained significant popularity across various industries due to their unique combination of strength, durability, and versatility. The specific variant known as 3 8% perforated steel plate, characterized by its specific percentage of perforation and hole size, offers streamlined performance in diverse applications. This article delves into the characteristics, applications, and advantages of the 3 8% perforated steel plate, shedding light on why it is an essential material in modern engineering and design.

Characteristics of 3 8% Perforated Steel Plate

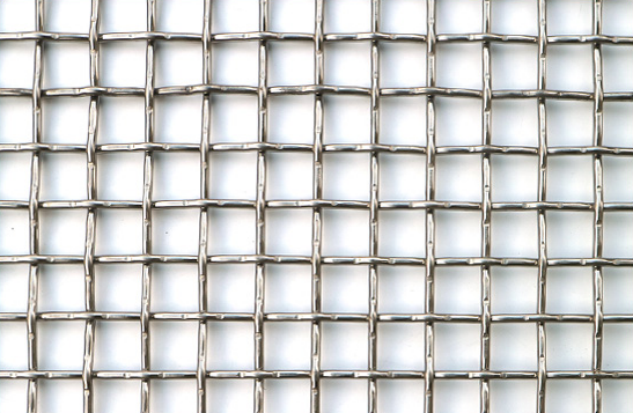

The designation 3 8% signifies that the steel plate has 3% of its surface area occupied by holes, with the dimensions of these holes being a key feature determining its usability. The uniformity and spacing of the perforations, along with their diameter, are crucial in defining the plate's mechanical properties and aesthetic appeal. Typically, perforated plates are produced using high-precision methods that ensure the holes are evenly distributed, providing consistent structural integrity.

Moreover, the choice of material for the perforated plate often includes stainless steel, carbon steel, and galvanized steel. Stainless steel variants are particularly popular due to their corrosion resistance, making them suitable for outdoor applications and in environments that involve exposure to moisture and chemicals.

Applications of 3 8% Perforated Steel Plate

The versatility of perforated steel plates allows them to be used in a multitude of settings. Here are some common applications associated with the 3 8% perforated steel plate

1. Architectural Design In contemporary architecture, the aesthetic qualities of perforated steel plates are leveraged to create visually appealing facades, screens, and decorative elements. The unique pattern formed by the perforations can enhance design features while allowing light and air to pass through.

2. Industrial Uses In the manufacturing and industrial sector, these plates are often used as structural components such as stairs, platforms, and walkways where slip resistance and weight reduction are crucial. The perforations can help in the dissipation of heat or light filtration, enhancing safety and functionality.

3 8 perforated steel plate

3. Acoustic Panels Due to their ability to absorb and diffuse sound, perforated steel plates are utilized in the design of acoustic panels in theaters, auditoriums, and recording studios. The holes in the plate help to minimize sound reflection, creating an optimal listening environment.

4. Filtration In chemical processing and water treatment facilities, perforated plates serve as filters, allowing certain particles to pass through while retaining larger particles. The size and arrangement of the perforations can be tailored to the specific filtration requirements.

5. Safety Gratings The use of perforated steel plates as grating in industrial environments ensures safety while allowing for effective drainage and airflow. They can be installed in high-traffic areas without compromising on strength or support.

Advantages of Using 3 8% Perforated Steel Plate

The benefits of utilizing a 3 8% perforated steel plate extend beyond just functionality. Some notable advantages include

- Weight Reduction The perforated design allows for a lighter material without sacrificing structural strength, making it ideal for applications where weight is critical. - Enhanced Aesthetics The visual appeal of perforated plates adds an artistic touch to various designs, making them a favorite for architects and interior designers.

- Improved Ventilation and Airflow The strategic hole placement in the plate facilitates better airflow, which is beneficial in many industrial and architectural applications.

- Cost-Effective Given their durability and versatility, perforated steel plates often provide a long-term solution with reduced maintenance costs.

In conclusion, the 3 8% perforated steel plate stands out as a valuable material in today's manufacturing and design landscape. Its unique properties and diverse applications make it an asset across numerous industries, enabling innovative solutions while maintaining strength and aesthetic appeal. As technology advances, the potential for further applications and enhancements in perforated plate design continues to evolve, promising to meet the growing demands of modern engineering.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.