Understanding 316 Stainless Steel Perforated Sheets

In the realm of modern construction and industrial applications, materials play a pivotal role in determining the integrity, aesthetics, and longevity of a project. One such material that has garnered attention for its versatility and resilience is the 316 stainless steel perforated sheet. With its unique properties and diverse applications, it stands out as a prime choice for various industries.

What is 316 Stainless Steel?

316 stainless steel is an alloy that contains molybdenum, making it more resistant to corrosion than its predecessor, 304 stainless steel. This enhanced corrosion resistance is particularly vital in environments where exposure to saltwater and other corrosive agents is prevalent, making it a favorite among marine, chemical, and food processing sectors. The alloy composition comprises approximately 16% chromium, 10% nickel, and 2% molybdenum, which collectively contribute to its strength and durability.

Characteristics of 316 Stainless Steel Perforated Sheets

Perforated sheets are metal plates with holes punched into them in various patterns. The 316 stainless steel perforated sheet combines the advantages of both perforation and the properties of stainless steel. Some notable characteristics include

1. Corrosion Resistance As mentioned, the presence of molybdenum in 316 stainless steel grants it superior resistance against corrosive environments. This makes it suitable for outdoor applications and industries dealing with harsh chemicals.

2. Strength and Durability The structural integrity of 316 stainless steel contributes to its robustness, making it ideal for applications requiring mechanical strength and durability.

3. Aesthetic Appeal The sleek, polished finish of stainless steel gives perforated sheets an aesthetic quality that is beneficial in architectural applications. They can be used as decorative facades or interior design elements.

4. Lightweight yet Strong The perforation process reduces the weight of the sheet without compromising its strength. This feature is particularly advantageous in applications where weight savings are crucial.

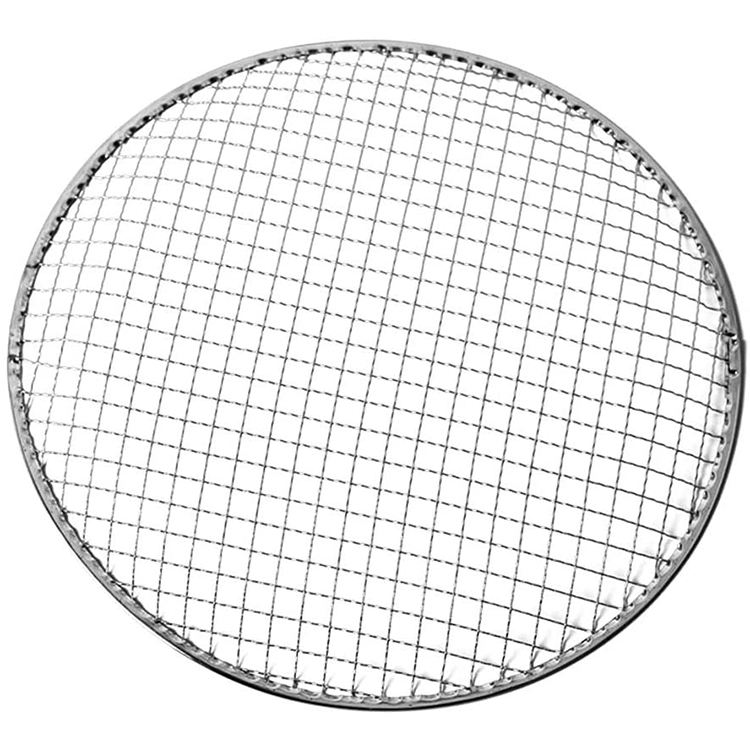

316 stainless steel perforated sheet

5. Versatility 316 stainless steel perforated sheets can be customized in terms of hole size, pattern, and thickness, making them suitable for a wide range of applications across different industries.

Applications of 316 Stainless Steel Perforated Sheets

Given their unique properties, 316 stainless steel perforated sheets find use in various applications

1. Architectural Features In contemporary design, they are often used for decorative screens, facade panels, and ceilings, providing both functionality and visual interest.

2. Industrial Uses In manufacturing and processing industries, they are utilized in filters, separators, and grates, owing to their strength and ability to withstand extreme conditions.

3. Marine Applications Their corrosion resistance makes them ideal for marine environments, including boat fittings, equipment, and safety rails.

4. Food Processing Given the material's non-reactive nature, 316 stainless steel perforated sheets are common in food processing equipment, ensuring safety and hygiene.

5. Environmental Applications These sheets are used in various environmental projects, including water filtration systems and waste management, where durability and resistance to corrosion are essential.

Conclusion

The popularity of 316 stainless steel perforated sheets can be attributed to their blend of strength, durability, and aesthetic qualities. Whether in architectural applications or industrial settings, their versatility makes them a preferred choice across multiple industries. By understanding the properties and advantages of this material, designers, engineers, and manufacturers can make informed decisions when selecting materials for their projects. The future of construction and manufacturing continues to evolve, and 316 stainless steel perforated sheets are set to play a significant role in this progress, offering solutions that combine form with function.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.