Understanding 316 Stainless Steel Grating Properties and Applications

316 stainless steel grating is a versatile and durable material widely used in various industrial applications. Known for its excellent corrosion resistance, particularly in marine and chemical environments, 316 stainless steel is a popular choice for grating where both durability and performance are essential.

One of the key characteristics of 316 stainless steel is its composition, which includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum is crucial as it enhances the alloy's resistance to pitting and crevice corrosion, making it ideal for harsh environments such as coastal areas or industries handling aggressive chemicals. This corrosion resistance is what sets 316 stainless steel apart from other grades, such as 304 stainless steel, which is also durable but lacks the same level of protection against saltwater and corrosive environments.

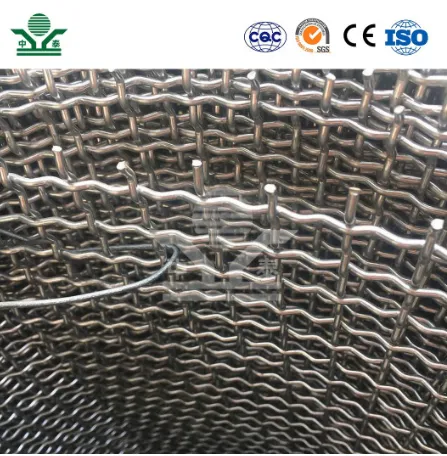

The manufacturing process of 316 stainless steel grating involves the welding of steel bars or rods to create a sturdy and stable product. Typically available in various styles, including heavy-duty, light-duty, and open mesh, stainless steel grating can be tailored to meet specific load-bearing requirements. This adaptability makes it suitable for numerous applications, ranging from walkways and platforms to stair treads and drainage covers.

316 stainless steel grating

In terms of design, 316 stainless steel grating provides excellent slip resistance, which is crucial for ensuring safety in areas with high foot traffic or machinery operation. The grating can be finished with a variety of surface treatments, such as galvanizing or powder coating, to enhance its aesthetic appeal while further improving its protective properties.

Moreover, the maintenance of 316 stainless steel grating is relatively minimal when compared to other materials. Its smooth surface is easy to clean, reducing the accumulation of dirt and contaminants. Regular cleaning can help preserve its appearance and longevity, making it an economical choice in the long run.

In conclusion, 316 stainless steel grating is an exceptional material that combines strength, durability, and resistance to corrosion. Whether used in marine environments, chemical plants, or other demanding settings, its properties make it a preferred choice among engineers and architects. The versatility of 316 stainless steel grating not only enhances safety in industrial applications but also offers sustainable long-term solutions that stand up to the challenges posed by various environmental factors. As industries continue to prioritize safety and durability, the importance of materials like 316 stainless steel will undoubtedly remain significant.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.