Jan . 26, 2025 04:20

Back to list

316 stainless steel grating

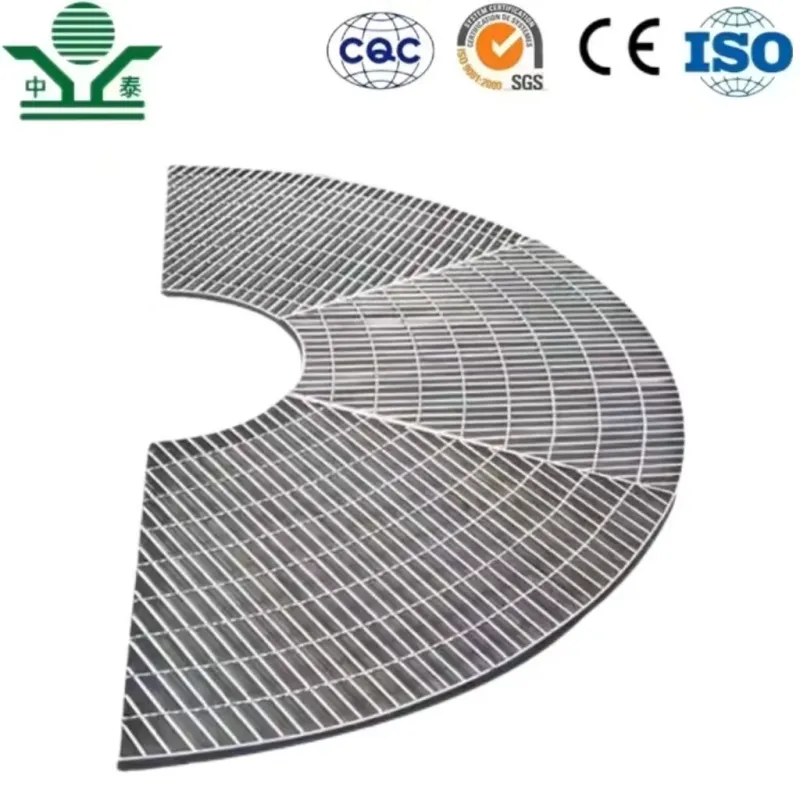

316 stainless steel grating has become a vital component in a variety of industries due to its superior durability, excellent corrosion resistance, and versatile applications. As an experienced professional in the field of industrial materials, I have encountered and examined numerous types of gratings. This specific alloy continues to demonstrate its superiority in myriad settings, making it a highly sought-after choice in both commercial and industrial sectors.

Furthermore, one cannot overlook the aesthetic appeal of 316 stainless steel grating in commercial and architectural applications. The sleek, modern look of stainless steel adds an element of sophistication to buildings, walkways, and decorative facades. Its reflective qualities can brighten spaces, and its clean lines offer a minimalist aesthetic that complements contemporary design trends. For architects and designers, 316 stainless steel grating provides not only functional utility but also a dynamic design element that resonates with environmentally conscious and innovative architectural philosophies. Trustworthiness in materials like 316 stainless steel grating is achieved through continuous testing and proven track records in the field. Clients and stakeholders can rely on comprehensive data and case studies that demonstrate its effectiveness and longevity across numerous installations worldwide. Reputable suppliers and manufacturers offer warranties and certifications, providing further assurance of the product’s quality and performance parameters. Sustainability is another critical aspect that cannot be ignored. 316 stainless steel is an environmentally friendly material, fully recyclable without a degradation of its properties. This factor aligns with the growing global emphasis on sustainable construction practices and the reduction of carbon footprints. Companies using 316 stainless steel grating can promote their commitment to environmental stewardship, enhancing their corporate image and establishing trust with eco-conscious consumers. In conclusion, the utilization of 316 stainless steel grating is a testament to its unparalleled performance in demanding environments. Its corrosion resistance, strength, and adaptability make it a versatile choice for numerous applications. Professionals seeking reliable, aesthetically pleasing, and sustainable solutions consistently turn to 316 stainless steel for grating needs. As industries continue to evolve, the demand for high-quality, durable materials will only increase, cementing the role of 316 stainless steel grating as a cornerstone in infrastructure and innovation.

Furthermore, one cannot overlook the aesthetic appeal of 316 stainless steel grating in commercial and architectural applications. The sleek, modern look of stainless steel adds an element of sophistication to buildings, walkways, and decorative facades. Its reflective qualities can brighten spaces, and its clean lines offer a minimalist aesthetic that complements contemporary design trends. For architects and designers, 316 stainless steel grating provides not only functional utility but also a dynamic design element that resonates with environmentally conscious and innovative architectural philosophies. Trustworthiness in materials like 316 stainless steel grating is achieved through continuous testing and proven track records in the field. Clients and stakeholders can rely on comprehensive data and case studies that demonstrate its effectiveness and longevity across numerous installations worldwide. Reputable suppliers and manufacturers offer warranties and certifications, providing further assurance of the product’s quality and performance parameters. Sustainability is another critical aspect that cannot be ignored. 316 stainless steel is an environmentally friendly material, fully recyclable without a degradation of its properties. This factor aligns with the growing global emphasis on sustainable construction practices and the reduction of carbon footprints. Companies using 316 stainless steel grating can promote their commitment to environmental stewardship, enhancing their corporate image and establishing trust with eco-conscious consumers. In conclusion, the utilization of 316 stainless steel grating is a testament to its unparalleled performance in demanding environments. Its corrosion resistance, strength, and adaptability make it a versatile choice for numerous applications. Professionals seeking reliable, aesthetically pleasing, and sustainable solutions consistently turn to 316 stainless steel for grating needs. As industries continue to evolve, the demand for high-quality, durable materials will only increase, cementing the role of 316 stainless steel grating as a cornerstone in infrastructure and innovation.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

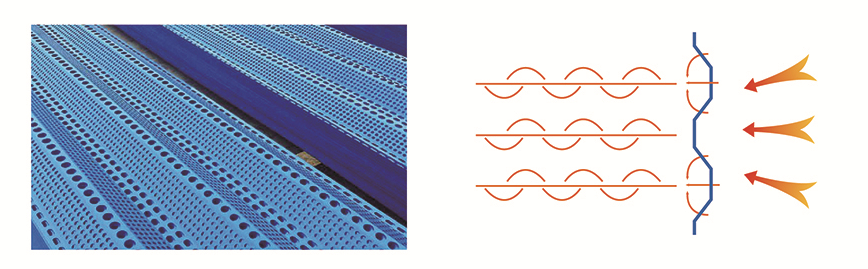

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP