The Versatility of 1% 208% Perforated Steel Sheets

Perforated steel sheets have become a staple component in various industries, owing to their unique characteristics and applications. Among the myriad of perforation patterns and thicknesses available, the 1% 208% perforated steel sheet stands out for its versatility and functionality. This article will delve into the features, benefits, and applications of this specific type of perforated steel, demonstrating why it is a preferred choice for engineers and designers alike.

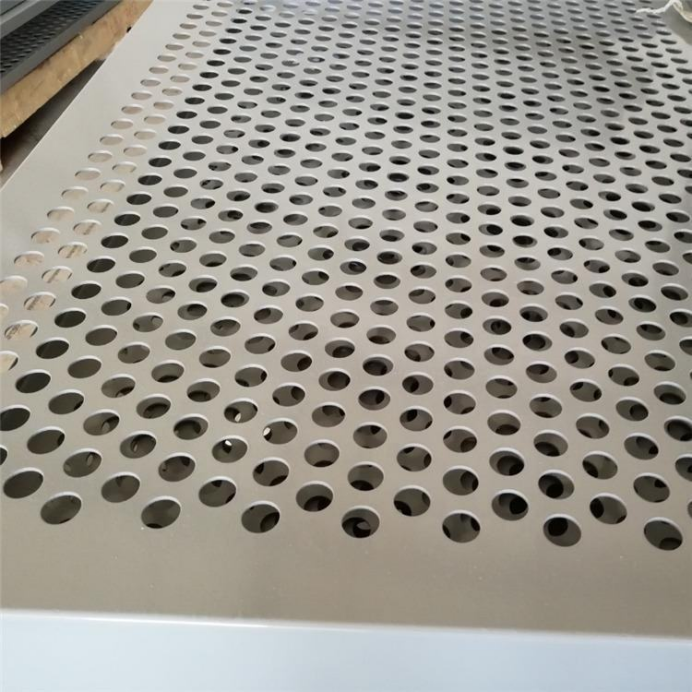

Understanding Perforated Steel Sheets

Perforated steel sheets are metal sheets that have been punctured with a series of holes to create a pattern. These holes can vary in size, shape, and spacing, allowing for numerous design configurations. The percentages in 1% 208% refer to the percentage of open area to solid area in the sheet—1% being the total coverage by the solid metal and 208% referring to the size and spacing of the perforations. This relationship between solid and void area is critical, as it dictates the sheet’s strength, weight, and functionality.

Benefits of 1% 208% Perforated Steel Sheets

1. Lightweight Yet Strong One of the primary benefits of using a perforated sheet is that it retains the strength of steel while significantly reducing its weight. This lightweight nature makes it ideal for applications where weight is a concern, such as in construction and manufacturing.

2. Aesthetic Appeal The unique perforation designs not only serve functional purposes but also add visual interest. The 1% 208% sheet can be used architecturally to create stunning facades, partitions, and other decorative elements that enhance the overall design of a project.

3. Ventilation and Light Transmission The holes in the perforated steel sheet allow for air and light to pass through, making them perfect for applications in areas that require ventilation or natural light, such as in HVAC systems or light fixtures.

4. Customized Solutions Manufacturers can customize the hole size, pattern, and arrangement, providing tailored solutions to meet specific project requirements. This flexibility means that architects and engineers can achieve their desired results without compromising on performance.

5. Durability and Corrosion Resistance Steel is known for its robustness, and when treated, it can resist corrosion effectively. Perforated steel sheets can be coated or galvanized, increasing their longevity and suitability for outdoor applications, such as in architecture or garden design.

1 8 perforated steel sheet

Applications Across Industries

The applications of 1% 208% perforated steel sheets are vast and varied, making them indispensable in multiple sectors

1. Construction and Architecture Used in building facades, ceilings, and wall cladding, perforated steel can create striking visual elements while providing structural benefits.

2. Industrial Settings These sheets are commonly used in machinery guards, screens, and safety barriers due to their strong yet lightweight nature. They also allow for cooling and airflow in industrial environments.

3. Interior Design In commercial spaces, perforated sheets can serve as decorative panels or ceilings, contributing to acoustic performance and aesthetics.

4. Transportation The automotive and aerospace industries utilize perforated steel to reduce weight while maintaining structural integrity in various components.

5. Furniture Design Designers have embraced the use of perforated steel in creating modern, industrial-style furniture that is both functional and stylish.

Conclusion

The 1% 208% perforated steel sheet exemplifies the blend of functionality and aesthetics that is prized in modern design and construction. With its lightweight properties, aesthetic versatility, and myriad applications, it stands as a testament to the innovation of perforated materials. Whether used in architecture, manufacturing, or product design, this type of steel sheet continues to enable creative solutions that meet the demands of the present while paving the way for future advancements in various industries. As trends evolve and new applications emerge, the role of perforated steel sheets will only grow, solidifying their place as a critical material in the fabric of modern engineering and design.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.