Understanding 16% Gauge Perforated Sheet Metal Features and Applications

When it comes to manufacturing and industrial applications, one of the significant materials utilized is perforated sheet metal. Among the various gauges available, 16-gauge perforated sheet metal is one of the most popular choices due to its unique combination of strength, versatility, and aesthetic appeal. In this article, we'll explore the characteristics, benefits, and applications of 16-gauge perforated sheet metal.

Characteristics of 16-Gauge Perforated Sheet Metal

The term gauge refers to the thickness of the metal sheet. A 16-gauge sheet measures approximately 0.0598 inches (1.52 mm) thick, making it a robust option for various applications. The perforation process involves creating holes in the sheet through a punching or laser cutting method, resulting in numerous patterns that can be customized to meet specific needs. The holes can vary in size, shape, and arrangement, influencing both aesthetics and functionality.

The perforation not only allows for ventilation and drainage but also reduces the weight of the sheet without significantly compromising its structural integrity. The regular spacing of holes makes it easier for air and light to filter through, enhancing its usability in various contexts.

Benefits of 16-Gauge Perforated Sheet Metal

1. Strength and Durability The thickness of 16-gauge sheet metal provides excellent strength, making it suitable for applications that require resilience and longevity. It can withstand harsh environments, be it indoors or outdoors.

2. Versatility One of the standout features of perforated sheet metal is its versatility. It can be used in a variety of industries, including construction, automotive, and manufacturing. The customizable hole patterns allow it to meet specific functional requirements, whether for filtering, shielding, or decorative purposes.

3. Aesthetic Appeal Perforated sheets offer an attractive design element that can enhance the appearance of architecture and interior spaces. The modern and sleek look of perforated metal makes it a favorite choice among designers and architects.

16 gauge perforated sheet metal

4. Lightweight Despite its strength, 16-gauge perforated sheet metal is relatively lightweight compared to solid metal sheets, making it easier to handle and install. This characteristic is especially important in applications where weight is a significant concern.

Applications of 16-Gauge Perforated Sheet Metal

1. Architectural Features In modern architecture, perforated metal is often used for facades, screens, railings, and ceilings, where it enhances aesthetics while providing functionality.

2. Industrial Use In various manufacturing processes, 16-gauge perforated sheets are used for machine guards, safety barriers, and filter screens, offering both protection and efficiency.

3. Furniture Design With its stylish look and robust quality, perforated metal is increasingly being used in furniture design, such as chairs, tables, and shelving units, providing both strength and a contemporary feel.

4. Automotive Applications Perforated sheet metal is used in vehicles for components like air filters, heat shields, and sound-dampening panels. Its ability to withstand high temperatures and harsh conditions makes it ideal for automotive environments.

5. Event and Exhibition Stands The lightweight nature and visual appeal of 16-gauge perforated sheets make them ideal for trade show displays and exhibition stands, allowing for creative designs that can attract visitors.

In conclusion, 16-gauge perforated sheet metal is a highly functional and versatile material that serves numerous applications across different industries. Its combination of strength, aesthetic appeal, and customizable features make it an essential component in modern design and manufacturing. Whether you’re in construction, manufacturing, or design, understanding the benefits and applications of this material can help you make informed decisions in your projects.

-

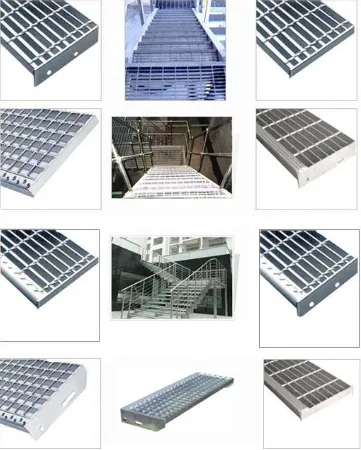

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.