The Versatility of 1% 4% Perforated Stainless Steel Plates

Perforated stainless steel plates have gained significant recognition across various industries due to their unique combination of aesthetic appeal, functionality, and durability. Among these materials, the 1% 4% perforated stainless steel plate stands out, not just for its performance characteristics but also for its diverse applications.

What is a Perforated Stainless Steel Plate?

A perforated stainless steel plate is a sheet of stainless steel that has been manufactured with a series of holes in a specified pattern. The 1% 4% refers to the specific alloy composition used in these stainless steel plates, which often indicates the percentage of chromium and nickel, two key elements that bolster the material’s resistance to corrosion and enhance its strength.

Properties of 1% 4% Perforated Stainless Steel Plates

One of the most compelling features of 1% 4% perforated stainless steel plates is their excellent corrosion resistance. Stainless steel is known for its ability to withstand harsh environments, making it an ideal choice for applications in various sectors, including agriculture, food processing, and construction. Additionally, the ability to perforate the stainless steel means that the material can maintain its strength while also being lightweight, offering versatility that solid sheets simply cannot.

Moreover, the perforations provide functional benefits, such as improved airflow, drainage, and light transmission. This makes these plates perfect for use in applications like grating, screening, and decorative elements in architecture. The aesthetic quality of perforated stainless steel also allows designers to create visually striking surfaces while still achieving practical results.

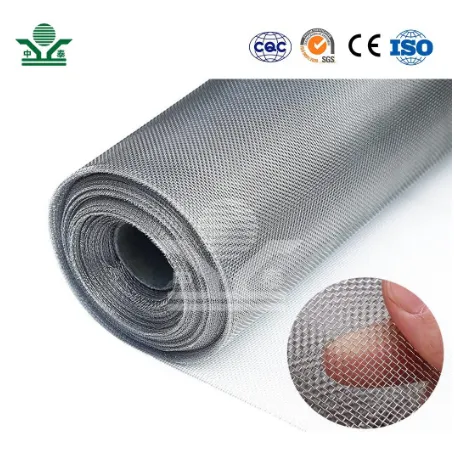

1 4 perforated stainless steel plate

Applications of 1% 4% Perforated Stainless Steel Plates

The applications for 1% 4% perforated stainless steel plates are expansive. In the architecture and design sector, they are frequently used in facades and partitions where both beauty and functionality are required. These plates can help regulate temperature by allowing air circulation while simultaneously reducing glare and providing privacy.

In the food and beverage industry, these plates can be incorporated into equipment and machinery, facilitating the safe processing of food items while maintaining hygiene standards. Their ease of cleaning, coupled with resistance to staining and corrosion, makes them a preferred choice for surfaces that come into contact with food.

Furthermore, 1% 4% perforated stainless steel is commonly used in industrial applications such as filtration systems where the material's strength, durability, and corrosion resistance are critical. This makes them suitable for environments that demand robust materials, whether it be in oil and gas, pharmaceuticals, or chemical manufacturing.

Conclusion

The 1% 4% perforated stainless steel plate offers a versatile solution that combines durability, functionality, and aesthetic appeal. Its diverse applications across multiple industries underscore its significance in modern manufacturing and design. As technology advances, it is likely that the uses of perforated stainless steel will continue to expand, offering creative solutions that meet the evolving needs of various sectors. Investing in this material means investing in quality, longevity, and functionality—attributes that are crucial in today’s fast-paced and demanding industrial landscape.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.