In the realm of industrial applications, round perforated metal sheets are essential components that serve various purposes across multiple sectors. These sheets are characterized by their unique design, featuring evenly spaced holes that allow for airflow, drainage, and light penetration. The precision of hole diameter and pitch in these sheets is crucial for ensuring optimal performance. When manufacturers produce round perforated metal, the tolerances for hole size and spacing must be strictly controlled to meet the specific needs of different applications.

The significance of precision in round hole perforated stainless steel sheets cannot be overstated. For instance, in the construction industry, these sheets are often used for facades, railings, and screens. The aesthetic appeal of a well-designed perforated sheet can enhance the overall look of a building while providing functional benefits. However, if the holes are not uniformly sized or spaced, the visual impact may be compromised, and the structural integrity could be at risk. Therefore, manufacturers must adhere to stringent quality control measures to ensure that each sheet meets the required specifications.

Moreover, industries such as food processing and pharmaceuticals utilize round hole perforated sheets for filtration and separation processes. In these applications, even minor deviations in hole diameter can lead to significant operational issues, such as reduced efficiency or contamination. Thus, precision in manufacturing these sheets is not just a matter of aesthetics; it is a critical factor that directly affects functionality and safety. As a domestic foreign trade wholesaler, we pride ourselves on providing high-quality round perforated metal sheets that meet the highest standards of precision and reliability.

Quality Control and Tolerance Levels in Manufacturing

Quality control is a fundamental aspect of producing round perforated metal sheets that meet industry standards. Tolerance levels refer to the permissible limits of variation in a physical dimension. In the case of perforated metal, this includes the diameter of the holes and the pitch, which is the distance between the centers of adjacent holes. Maintaining tight tolerances is crucial for ensuring that the sheets perform as intended in their respective applications.

For example, when producing round hole perforated stainless steel sheets, manufacturers often adhere to specific tolerance levels that dictate how much variation is acceptable in hole size and spacing. A standard tolerance might allow for a deviation of only a few thousandths of an inch. This level of precision ensures that the sheets can effectively filter materials or allow airflow without compromising structural integrity. If the tolerances are too loose, it could result in inconsistent performance, leading to operational inefficiencies or even failures in critical applications.

In addition to tolerance levels, employing advanced quality control techniques is essential for maintaining the high standards required for round hole perforated sheets. This may involve using precision measurement tools and techniques, such as laser measuring systems, to verify that each sheet meets the specified criteria. Regular audits and inspections throughout the manufacturing process also help identify any potential issues before they become significant problems. By prioritizing quality control and adhering to strict tolerance levels, we ensure that our round perforated metal sheets consistently deliver exceptional performance and reliability.

The Role of Precision in Application-Specific Designs

Different industries have varying requirements for round perforated metal sheets, and precision plays a pivotal role in meeting these specific needs. For instance, in the automotive sector, perforated metal is often used for sound dampening and ventilation. Here, the exact hole diameter and pitch are critical to achieving the desired acoustic properties. If the holes are too large or spaced incorrectly, the intended sound absorption may not occur, resulting in an undesirable driving experience.

Similarly, in the architectural field, round perforated metal is frequently utilized for decorative facades and sunshades. The aesthetic appeal of these designs relies heavily on the uniformity of the perforations. Architects and designers expect precise hole sizes and consistent spacing to create visually striking patterns that enhance the overall building design. Any discrepancies in the perforated pattern can detract from the visual impact, making precision a non-negotiable aspect of production.

Furthermore, industries that require round hole perforated stainless steel sheets for filtration processes demand even stricter adherence to precision. In applications such as water treatment or chemical processing, the size and spacing of the holes must be meticulously controlled to ensure that contaminants are effectively filtered out while allowing the desired flow rates. Deviations in hole diameter can lead to inefficiencies, increased costs, and potential safety hazards. Thus, the importance of precision in these applications cannot be overstated, as it directly impacts both performance and safety.

Ensuring Reliability Through Advanced Manufacturing Techniques

To meet the rigorous demands of precision in producing round perforated metal sheets, manufacturers are increasingly adopting advanced manufacturing techniques. Technologies such as CNC (Computer Numerical Control) machining and laser cutting have revolutionized the way perforated metal is produced. These methods allow for unparalleled accuracy in creating holes of specific diameters and pitches, ensuring that each sheet meets the exact specifications required by various industries.

CNC machining, for instance, enables manufacturers to program precise dimensions into their equipment, resulting in uniform hole sizes and spacing across large production runs. This consistency is vital for maintaining quality and reliability, especially when producing round hole perforated sheets for critical applications. Laser cutting further enhances this precision by using focused beams of light to create clean, accurate cuts without damaging the surrounding material. This method minimizes the risk of burrs or rough edges, which can affect the performance of the final product.

Moreover, investing in high-quality materials is essential for ensuring the longevity and durability of round perforated metal sheets. Stainless steel, known for its corrosion resistance and strength, is a popular choice for many applications. By using premium materials alongside advanced manufacturing techniques, we can guarantee that our products not only meet but exceed the expectations of our clients. This commitment to quality and precision positions us as a trusted supplier in the market, ready to fulfill the diverse needs of our customers.

FAQs: Precision in Round Perforated Metal Sheets

What are round perforated metal sheets used for?

Round perforated metal sheets are used in various applications, including construction, automotive, and filtration processes, providing functionality and aesthetic appeal.

Why is precision important in round hole perforated stainless steel sheets?

Precision is crucial because it ensures optimal performance, safety, and aesthetic quality, particularly in applications requiring specific hole sizes and spacing.

How do manufacturers maintain quality control for perforated metal?

Manufacturers maintain quality control through strict adherence to tolerance levels, regular inspections, and the use of advanced measurement tools throughout the production process.

What technologies are used to produce round hole perforated sheets?

Technologies such as CNC machining and laser cutting are commonly used to achieve high precision in producing round hole perforated sheets.

What materials are typically used for round perforated metal sheets?

Common materials include stainless steel, aluminum, and carbon steel, each chosen for its specific properties and suitability for various applications.

Discover Our High-Quality Round Perforated Metal Sheets Today

Explore our extensive range of round perforated metal sheets that meet the highest standards of precision and quality. Visit our website to place your order and elevate your projects with our reliable products. Your satisfaction and safety are our top priorities!

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

BeritaJul.10,2025

-

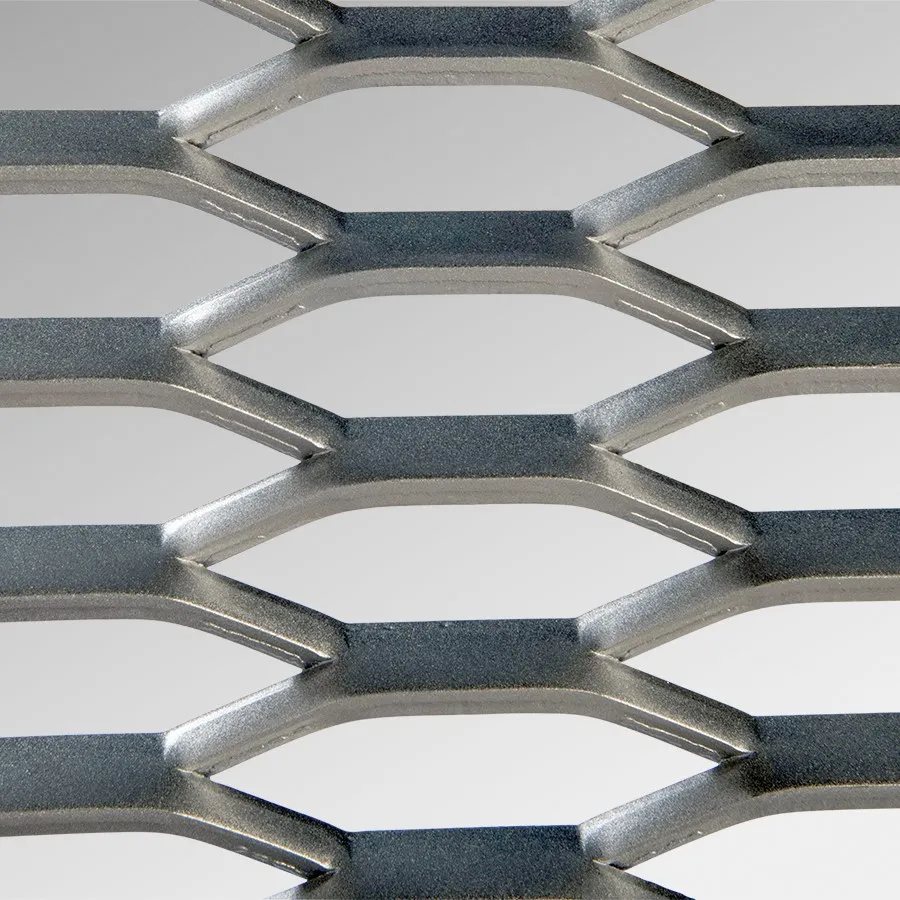

The Versatility and Strength of Stainless Expanded Metal Mesh

BeritaJul.10,2025

-

Load Calculations in Steel Grating Platforms

BeritaJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

BeritaJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

BeritaJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

BeritaJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.