Welded Steel Grating An Overview of Its Applications and Advantages

Welded steel grating is a versatile and widely used material in various industries, known for its strength, durability, and efficiency. Made from carbon steel or stainless steel, welded steel grating is constructed by welding intersecting bars together, forming a grid-like structure. This fabrication method enhances the load-bearing capacity and structural integrity of the grating. In this article, we will explore the various applications of welded steel grating, its advantages, and maintenance requirements.

Applications of Welded Steel Grating

Welded steel grating is commonly used in a range of industries, including construction, manufacturing, and transportation. One of its most familiar applications is in flooring systems. The grating allows for excellent drainage, ensuring that water can flow easily through the spaces between the bars. This characteristic makes it ideal for areas that are prone to spills or require frequent cleaning.

In industrial settings, welded steel grating is often employed as walkways and platforms. Its slip-resistant surface provides safety for workers, while its ability to support heavy loads ensures that it can withstand the demands of heavy machinery and foot traffic. Furthermore, due to its open design, welded steel grating allows for the efficient passage of air, light, and sound—making it an ideal choice for environments such as factories, warehouses, and refineries.

Another significant application of welded steel grating is in the construction of stairs and ramps. By installing grating on stair treads, businesses can enhance safety for employees and visitors. The same applies to ramps, where the lightweight yet strong structure minimizes the risk of accidents during movement.

In addition to these uses, welded steel grating can be found in various architectural applications

. It is often used in decorative features, such as balustrades and fences, where its aesthetic appeal can complement a modern design. Additionally, the versatility of welded steel grating allows for customization in size, spacing, and bar thickness, enabling it to meet specific design requirements.Advantages of Welded Steel Grating

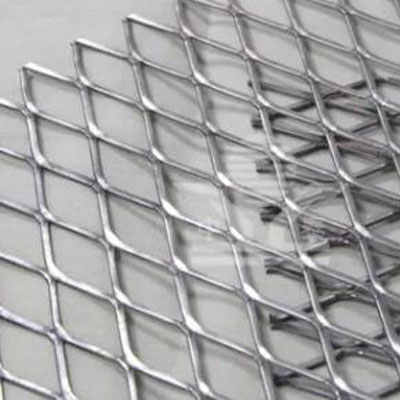

welded steel grating

There are several key advantages that welded steel grating offers over other types of flooring materials. Among these, durability is paramount. Steel grating is resistant to impact and can endure harsh environmental conditions, making it suitable for both indoor and outdoor applications. Additionally, when treated with a protective coating, it can resist corrosion, increasing its lifespan significantly.

Lightweight yet robust, welded steel grating is easy to handle and install. This quality not only reduces labor costs but also allows for quicker project execution. The open design of the grating allows for easy inspection and maintenance of the underlying structures, making it a practical choice for industrial applications.

Another essential attribute is its eco-friendliness. Welded steel grating is often made from recycled materials and is itself fully recyclable. Its longevity and minimal maintenance needs contribute to reducing waste, making it a sustainable option for construction projects.

Maintenance of Welded Steel Grating

Although welded steel grating is designed to be durable, regular maintenance is still essential to ensure its longevity. Routine inspections should be conducted to check for signs of wear, corrosion, or structural damage. Cleaning the grating to remove debris, oil, or chemicals will help maintain its slip-resistant properties and enhance safety.

In environments where the grating is constantly exposed to moisture or harsh chemicals, applying a protective coating can extend its lifespan. Additionally, any damaged sections should be repaired or replaced promptly to avoid compromising safety and reliability.

Conclusion

Welded steel grating is a robust, versatile, and efficient material with numerous applications across various industries. Its combination of strength, functionality, and aesthetic appeal makes it a popular choice in many construction and architectural projects. With regular maintenance and the right protective measures, welded steel grating can provide long-lasting solutions tailored to the specific needs of any environment. As industries continue to seek durable and sustainable materials, welded steel grating will undoubtedly remain a valuable asset in the world of construction and manufacturing.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.