जानेवारी . 22, 2025 01:29

Back to list

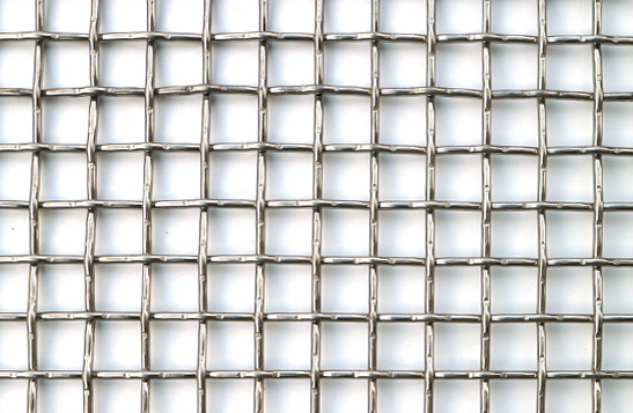

steel grating thickness

Steel grating is an indispensable component in modern industrial infrastructure, offering a blend of durability, strength, and versatility. One of the crucial factors impacting the performance and application of steel grating is its thickness. Understanding the significance of steel grating thickness can significantly enhance its utility in various projects, ensuring efficiency and safety.

The expertise of the manufacturer is another factor that ensures the optimal thickness of steel grating is used. Reputable manufacturers usually conduct rigorous testing and adhere to international standards, thus guaranteeing the quality and specifications of steel grating products. They understand how variations in thickness can impact performance and provide guidance on the best options for your specific needs. Selecting a trusted supplier not only delivers a product that meets your requirements but also assures compliance with industry norms. Moreover, the influence of technological advancement cannot be overlooked when discussing steel grating thickness. Modern manufacturing techniques have enabled the production of gratings with varying thicknesses without compromising on quality. This variation helps in customizing solutions for unique requirements, offering a balance between weight, cost, and utility. Finally, the installation process also underscores the importance of choosing the correct thickness. Skilled installation teams can make a significant difference in optimizing the functionality and lifespan of the steel grating. Properly trained personnel will ensure that the grating is handled and installed correctly, considering the thickness to avoid bending or unsuitable fits that could compromise safety. In conclusion, the thickness of steel grating is a fundamental attribute that influences its performance across various applications. Its selection should be carefully evaluated based on load capacity, environmental resistance, application requirements, manufacturer expertise, technological capabilities, and installation practices. By paying attention to these details, businesses can ensure the steel gratings they choose will deliver safety, reliability, and efficiency, bolstering the infrastructure they serve. Emphasizing the correct thickness not only maximizes the effectiveness of the grating but also aligns with the industry's best practices, offering a product that stands up to both present and future demands.

The expertise of the manufacturer is another factor that ensures the optimal thickness of steel grating is used. Reputable manufacturers usually conduct rigorous testing and adhere to international standards, thus guaranteeing the quality and specifications of steel grating products. They understand how variations in thickness can impact performance and provide guidance on the best options for your specific needs. Selecting a trusted supplier not only delivers a product that meets your requirements but also assures compliance with industry norms. Moreover, the influence of technological advancement cannot be overlooked when discussing steel grating thickness. Modern manufacturing techniques have enabled the production of gratings with varying thicknesses without compromising on quality. This variation helps in customizing solutions for unique requirements, offering a balance between weight, cost, and utility. Finally, the installation process also underscores the importance of choosing the correct thickness. Skilled installation teams can make a significant difference in optimizing the functionality and lifespan of the steel grating. Properly trained personnel will ensure that the grating is handled and installed correctly, considering the thickness to avoid bending or unsuitable fits that could compromise safety. In conclusion, the thickness of steel grating is a fundamental attribute that influences its performance across various applications. Its selection should be carefully evaluated based on load capacity, environmental resistance, application requirements, manufacturer expertise, technological capabilities, and installation practices. By paying attention to these details, businesses can ensure the steel gratings they choose will deliver safety, reliability, and efficiency, bolstering the infrastructure they serve. Emphasizing the correct thickness not only maximizes the effectiveness of the grating but also aligns with the industry's best practices, offering a product that stands up to both present and future demands.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP