Perforated Sheet Metal Panels Versatility and Applications

Perforated sheet metal panels have become a staple in various industries due to their unique properties, aesthetic appeal, and functional versatility. These panels are characterized by a series of holes punched into a metal sheet, creating both lightweight structures and visually appealing designs. This article explores various aspects of perforated sheet metal panels, including their manufacturing process, applications, benefits, and how they stand as a sustainable building material.

The Manufacturing Process

The manufacturing of perforated sheet metal panels begins with selecting the appropriate metal type, which can range from aluminum and stainless steel to copper and brass. The choice of metal often depends on the specific use case, environmental conditions, and desired aesthetics. Once the metal sheet is selected, it goes through a perforation process, which can be accomplished using different techniques such as laser cutting, punching, or drilling.

The pattern of holes can vary in size, shape, and arrangement, allowing for numerous design possibilities. For instance, a panel may feature uniform holes for a classic look, or random holes to achieve an artistic effect. After perforation, the panels can undergo additional treatments like coating, painting, or anodizing to enhance their durability and appearance.

Applications Across Industries

Perforated sheet metal panels find applications across a myriad of sectors, showcasing their adaptability. In architecture and construction, these panels are widely used for facades, sunscreens, and interior partitions. Their ability to allow light and air to pass through while providing some privacy makes them ideal for modern building designs.

In the automotive and aerospace industries, perforated panels contribute to lightweight structures without compromising strength and safety. They are often used in noise reduction applications, as the holes can help dissipate sound waves, making them a popular choice for vehicle interiors and engine compartments.

perforated sheet metal panels

Additionally, perforated panels serve essential roles in industrial settings. They can be used for filtration systems, grilles, and safety barriers. In the realm of furniture design, these panels have found their way into decorative pieces, offering both functionality and aesthetic appeal.

Advantages of Perforated Panels

The advantages of using perforated sheet metal panels are manifold. Firstly, their lightweight nature reduces transportation and installation costs without sacrificing structural integrity. Secondly, the air and light permeability of these panels can contribute to energy efficiency in buildings, as they help regulate temperature and reduce reliance on artificial lighting.

Moreover, perforated panels are inherently sustainable. Metals like aluminum and stainless steel are recyclable, which means that their environmental footprint is lower compared to many plastic alternatives. Their durability ensures that they can withstand harsh environmental conditions, reducing the need for frequent replacements and minimizing waste.

The design flexibility of perforated panels is another significant advantage. Architects and designers can create customized patterns to fit specific aesthetic requirements, ensuring that each application is unique. This has led to innovative uses in artistic installations and public spaces, where visual impact is as important as functionality.

Conclusion

Perforated sheet metal panels exemplify a harmonious balance between functionality, aesthetics, and sustainability. Their versatility allows them to be used in various industries, from construction and automotive to furniture design and industrial applications. With ongoing advancements in manufacturing techniques, the potential for creative applications continues to grow.

As the world increasingly prioritizes sustainability and energy efficiency, perforated sheet metal panels will likely play an integral role in the evolution of design and construction practices. Whether as structural elements or decorative features, these panels are sure to remain a popular choice in any innovative project that values both form and function. Their ability to adapt to the needs of various industries exemplifies why they are not just a trend but a lasting solution for modern challenges.

-

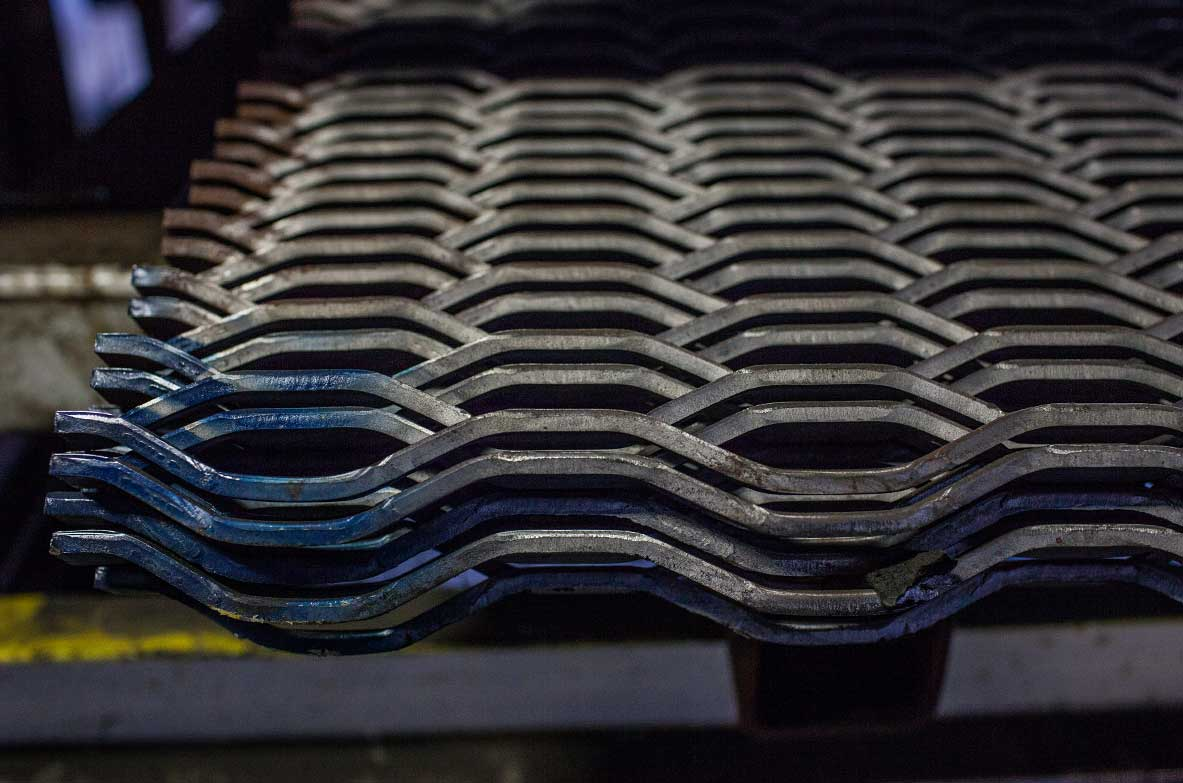

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.