Understanding Perforated Galvanized Sheet Metal Applications, Benefits, and Considerations

Perforated galvanized sheet metal is a versatile material that combines the durability of galvanized steel with the functionality of perforation. This specific type of metal is characterized by a series of holes, typically arranged in a specific pattern, which provides various benefits depending on the application. From architectural design to industrial uses, understanding the attributes of perforated galvanized sheet metal can greatly benefit engineers, architects, and manufacturers alike.

What is Galvanized Sheet Metal?

Galvanized sheet metal is steel that has been coated with a layer of zinc to prevent corrosion. The galvanization process involves immersing the steel in molten zinc or applying zinc through electroplating. This protective layer enhances the metal's longevity, especially in outdoor and harsh environments where rust is a significant concern. Galvanized steel is widely used in construction, automotive, HVAC systems, and appliances.

The Process of Perforation

Perforation involves creating holes or openings in the sheet metal, often using punches or lasers. The size, shape, and spacing of these holes can be customized to suit specific needs. While perforated metal is widely recognized for its aesthetic appeal, it also serves practical purposes. The perforation can improve airflow, reduce weight, and facilitate drainage, making it beneficial in various engineering applications.

Applications of Perforated Galvanized Sheet Metal

1. Architectural Applications In modern architecture, perforated galvanized sheet metal is often used for facades and screens. The patterns can provide a striking visual effect while still allowing light and air to penetrate. Architects leverage this material for both aesthetic enhancements and practical solutions, such as sun shading and privacy screens.

2. Industrial Uses In industrial settings, perforated galvanized sheet metal is used in machines, filters, and separators. The holes can be designed to facilitate the movement of air, fluids, or sound while minimizing the structure's weight. Such applications include noise barriers, exhaust systems, and ventilation grilles.

3. Furniture and Design This material is also increasingly being adopted in the furniture industry. Designers utilize perforated sheets to create modern, elegant pieces that are lightweight yet sturdy. Stools, tables, and decorative elements made from perforated galvanized metal can add a contemporary touch to any interior or exterior space.

4. Safety and Security Perforated metal can enhance safety in various applications. For example, it is often used to create protective barriers or fencing, allowing visibility while still providing security. The design can also prevent climbing and minimize risks associated with traditional fencing materials.

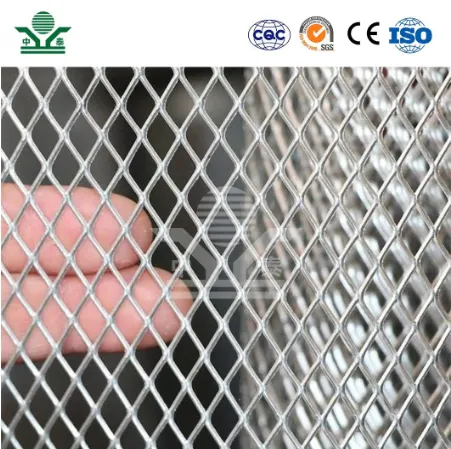

perforated galvanized sheet metal

Benefits of Using Perforated Galvanized Sheet Metal

- Durability The zinc coating significantly extends the life of the metal, making it resistant to rust and wear, which is especially valuable in outdoor environments. - Customization Manufacturers can customize the hole size, shape, and pattern, offering endless possibilities for design and utility specific to project requirements.

- Aesthetic Versatility The unique patterns and textures that perforation offers contribute to the aesthetic appeal, allowing designers to create eye-catching structures and products.

- Environmental Benefits Using galvanized sheet metal can contribute to sustainability efforts. Its longevity reduces the need for replacement and decreases waste over time.

Considerations When Choosing Perforated Galvanized Sheet Metal

When selecting perforated galvanized sheet metal for a project, several factors must be considered

- Hole Configuration Analyze the required hole size and pattern based on airflow, weight reduction, or visual appeal.

- Gauge of Metal The thickness of the sheet metal can significantly impact the overall strength and weight. Opt for a gauge that meets the specific demands of your application.

- Corrosion Resistance Even though galvanized metal is generally resistant to rust, the environment's specific conditions may necessitate additional coatings or treatments.

- Installation and Maintenance Assess the installation process and any maintenance that may be required over time to ensure the longevity of the installation.

In conclusion, perforated galvanized sheet metal is an incredibly functional and aesthetic material, applicable across various industries. By understanding its properties and potential uses, professionals can harness its capabilities to enhance both the design and functionality of their projects. Whether in construction, design, or manufacturing, this material's unique attributes continue to make it a popular choice worldwide.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.