Understanding Metal Grating Pricing Factors and Insights

Metal grating is an essential component in various industries, diligently utilized for flooring, walkways, platforms, and more. Its durability and ability to withstand heavy loads make it an attractive option for construction projects. However, when it comes to acquiring metal grating, one pivotal question arises—what influences its price?

Material Composition

The type of metal used in manufacturing grating significantly impacts its price. Common materials include steel, aluminum, and stainless steel. Generally, carbon steel is the most economical choice, making it a popular option for industrial applications. Conversely, stainless steel, known for its corrosion resistance and longevity, often comes at a higher price point. Aluminum grating is lightweight and resistant to corrosion, making it ideal for marine environments, but its cost can also be higher.

Manufacturing Process

The manufacturing process of metal grating also plays a crucial role in determining costs. The methods employed—whether welded, stamped, or forged—can influence both the quality and price. For instance, welded grating, which offers higher strength and load-bearing capabilities, may be costlier compared to fabricated alternatives.

Design Features

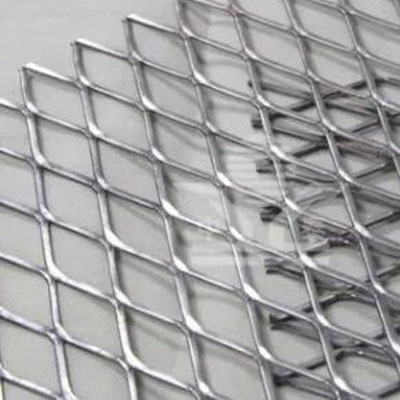

metal grating price

Metal grating can be customized depending on specific application requirements, including load-bearing capacities, surface finishes, and sizes. Additional features such as anti-slip surfaces or custom cutouts can increase production complexity and, consequently, the price. Understanding the specific needs of a project can help customers make cost-effective decisions.

Market Demand and Supply

The pricing of metal grating is also subject to fluctuations based on market demand and supply dynamics. For example, an uptick in construction projects can lead to an increased demand for grating, thus driving prices higher. Conversely, during times of economic downturn or reduced construction activity, prices may stabilize or decrease due to excess supply.

Regional Variations

Geographic location can also impact metal grating prices. Shipping costs, regional supply chain conditions, and local economic factors all contribute to price discrepancies across different markets. Buyers should consider sourcing locally to reduce transportation expenses and potentially avail themselves of lower pricing.

Conclusion

In summary, the price of metal grating is influenced by various factors, including material composition, manufacturing processes, design specifications, market conditions, and regional aspects. Understanding these elements can guide buyers in making informed decisions and securing the best value for their projects. As industries continue to evolve, staying attuned to market trends can aid in anticipating fluctuations in metal grating pricing, ultimately facilitating smarter procurement strategies. Whether for industrial, commercial, or architectural use, being knowledgeable about these factors ensures that projects are completed efficiently and cost-effectively.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.