जानेवारी . 20, 2025 15:45

Back to list

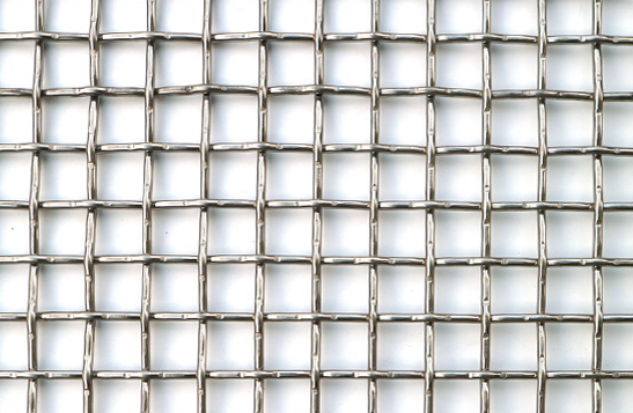

Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates

Heavy steel grating has established itself as an essential component in numerous industrial and commercial applications, known for its strength, durability, and practicality. Its variety and versatile nature make it a top choice for businesses aiming to enhance safety and efficiency in their operations.

From an environmental perspective, steel grating is a sustainable option. Steel is one of the most recyclable materials, and when grating reaches the end of its life cycle, it can be recycled multiple times without loss of quality. This reduces waste and is in line with global efforts towards sustainability. Businesses leveraging this aspect of steel grating contribute positively to their corporate social responsibility goals and bolster their brand reputation as environmentally conscious entities. Manufacturers and suppliers of heavy steel grating continually work on innovations to meet the dynamic needs of different industries. Enhanced production techniques lead to the development of products with better anti-slip properties and increased resistance to wear and tear. Through partnerships and focused research, companies strive to provide cutting-edge solutions that not only promise durability but also integrate seamlessly with technological advancements in fields like smart construction. Clients seeking heavy steel grating are advised to partner with suppliers who possess substantial experience and a track record of reliability. The credibility of a supplier often hinges on their ability to provide comprehensive support, from assisting in the selection process to delivering timely installations and offering post-installation maintenance advice. Trust in quality and service excellence forms the foundation of successful implementation and utilization of heavy steel grating systems. In summary, heavy steel grating embodies a blend of strength, customization, and sustainability, making it an invaluable asset across an array of industrial applications. By leveraging its benefits, industries not only improve safety and operational efficiency but also contribute to sustainability efforts. The trust and expertise of an experienced supplier can enhance overall project outcomes, ensuring that heavy steel grating continues to serve as a reliable solution for modern industrial challenges.

From an environmental perspective, steel grating is a sustainable option. Steel is one of the most recyclable materials, and when grating reaches the end of its life cycle, it can be recycled multiple times without loss of quality. This reduces waste and is in line with global efforts towards sustainability. Businesses leveraging this aspect of steel grating contribute positively to their corporate social responsibility goals and bolster their brand reputation as environmentally conscious entities. Manufacturers and suppliers of heavy steel grating continually work on innovations to meet the dynamic needs of different industries. Enhanced production techniques lead to the development of products with better anti-slip properties and increased resistance to wear and tear. Through partnerships and focused research, companies strive to provide cutting-edge solutions that not only promise durability but also integrate seamlessly with technological advancements in fields like smart construction. Clients seeking heavy steel grating are advised to partner with suppliers who possess substantial experience and a track record of reliability. The credibility of a supplier often hinges on their ability to provide comprehensive support, from assisting in the selection process to delivering timely installations and offering post-installation maintenance advice. Trust in quality and service excellence forms the foundation of successful implementation and utilization of heavy steel grating systems. In summary, heavy steel grating embodies a blend of strength, customization, and sustainability, making it an invaluable asset across an array of industrial applications. By leveraging its benefits, industries not only improve safety and operational efficiency but also contribute to sustainability efforts. The trust and expertise of an experienced supplier can enhance overall project outcomes, ensuring that heavy steel grating continues to serve as a reliable solution for modern industrial challenges.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP