The Versatility and Benefits of Galvanized Catwalk Grating

Galvanized catwalk grating is an essential element in industrial design, safety, and maintenance operations. Being integral to various sectors, this type of grating provides a robust and reliable platform for pedestrian traffic, equipment access, and maintenance activities in elevated positions.

What is Galvanized Catwalk Grating?

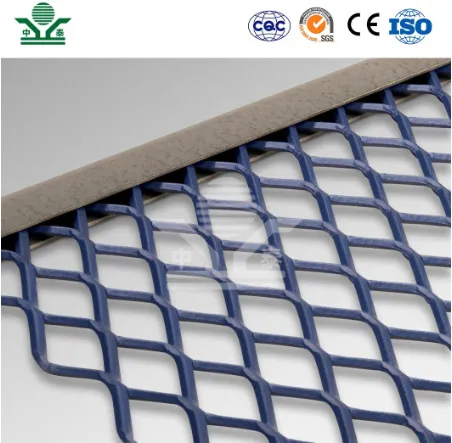

Galvanized catwalk grating is made from steel or other metals that have been coated with a layer of zinc to prevent corrosion. This galvanization process not only prolongs the life of the metal but also enhances its durability, making it suitable for both indoor and outdoor applications. The grating is often designed in various patterns, such as plain, serrated, or slotted, catering to different needs and preferences.

Applications of Galvanized Catwalk Grating

In industrial settings, galvanized catwalk grating is commonly used in factories, warehouses, and power plants. It serves as walkways over equipment, providing safety for personnel who need to monitor and maintain high-risk machinery. Additionally, this type of grating can be employed in the construction of platforms, staircases, and catwalks that require the passage of both personnel and equipment.

Furthermore, galvanized grating is indispensable in wastewater treatment facilities, where it facilitates access for maintenance and repairs while resisting the corrosive effects of chemicals present in the environment. The pharmaceutical and food processing industries also benefit from this grating due to its sanitary characteristics, as it allows for easy cleaning and maintenance, minimizing contamination risks.

Advantages of Using Galvanized Catwalk Grating

galvanized catwalk grating

1. Corrosion Resistance The primary advantage of galvanized catwalk grating is its resistance to corrosion. Galvanization creates a protective barrier that prevents rust formation, thus extending the lifespan of the grating even in harsh environments.

2. Strength and Durability Galvanized grating is designed to withstand heavy loads and extreme conditions. Its robust construction provides stability and safety, vital for areas where weight and high traffic are factors.

3. Slip Resistance Many galvanized grating options feature serrated surfaces, which enhance slip resistance. This is particularly important in sectors where personnel may be exposed to wet or oily conditions, reducing the risk of accidents and injuries.

4. Cost-Effectiveness While the initial investment in galvanized grating may be higher than other materials, its longevity and low maintenance costs make it a cost-effective choice in the long run.

5. Lightweight Design Despite its strength, galvanized catwalk grating is relatively lightweight. This characteristic simplifies installation and allows for easier handling compared to solid steel plates.

Conclusion

In conclusion, galvanized catwalk grating stands out as a crucial component in many industrial applications due to its combination of durability, safety, and cost-effectiveness. Whether used in manufacturing plants, construction sites, or wastewater facilities, its robust features provide an essential safety net for workers while ensuring efficient access to critical equipment. As industries continue to evolve, the reliance on galvanized catwalk grating will undoubtedly grow, reinforcing the importance of investing in quality grating systems that meet safety standards and operational needs. Through proper maintenance and selection, galvanized catwalk grating can significantly enhance workplace safety and efficiency for years to come.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.