1월 . 21, 2025 03:38

Back to list

steel grating cost per square foot

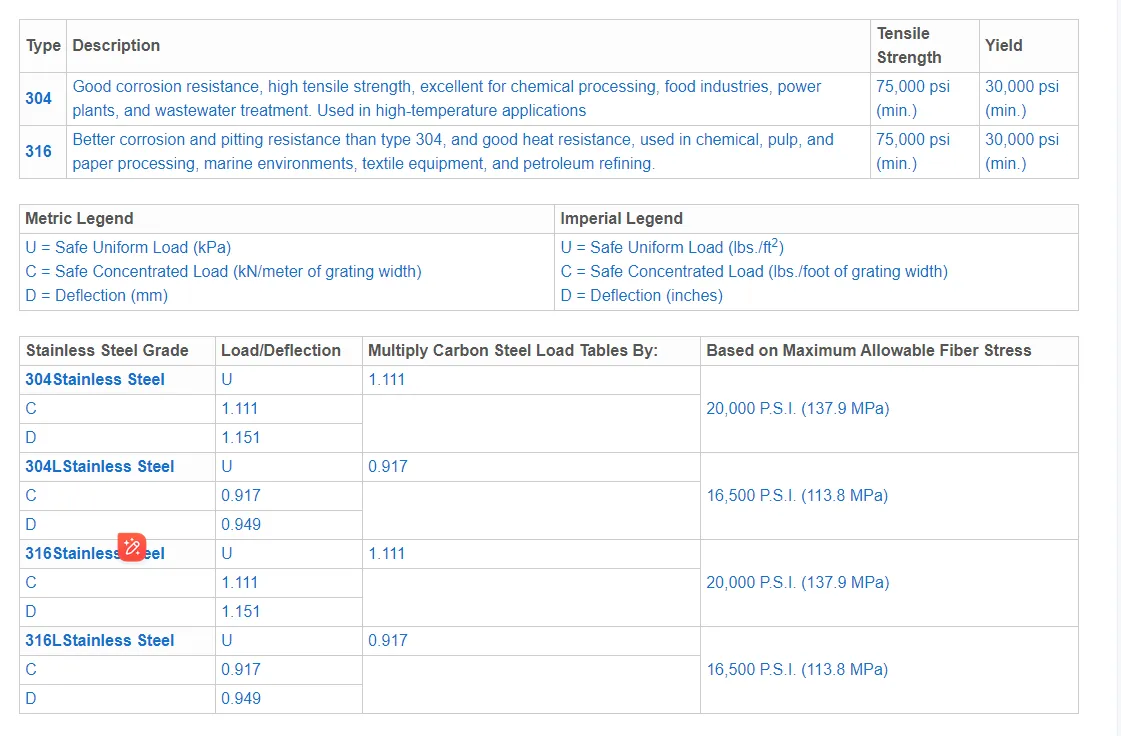

Understanding the cost of steel grating per square foot is essential for professionals and DIY enthusiasts involved in construction or renovation projects. Steel grating, a common material used in industrial and commercial infrastructures, offers several benefits including durability, strength, and ease of installation. However, grasping the cost dynamics can provide insights for budgeting and planning.

Market trends and supply chain factors play a significant role in determining steel grating costs per square foot. Global demand, exchange rates, and geopolitical factors can cause price fluctuations. Keeping abreast of market trends through industry reports and news updates can provide a competitive edge when estimating project budgets. Labor and installation costs must also be factored into total expenses. While our focus is material costs, installation requires skilled labor, particularly for larger or more complex installations. Given the variability of labor rates, localized estimates should be acquired to ensure accurate budgeting. Sometimes, choosing prefabricated systems can save time and reduce installation expenses, making them worth considering depending on the project scope. When analyzing costs, consider potential suppliers’ expertise and reputation. Vendors experienced in fabricating steel grating tend to offer better support, ensuring quality materials and adherence to specifications, leading to cost effectiveness in long-term projects. Establishing relationships with reliable suppliers can lead to favorable negotiations, discounts, and assurance in quality—an often overlooked yet valuable component in managing material costs. In conclusion, understanding the cost per square foot of steel grating requires a multi-faceted approach. Consideration of material choice, size, finish, and market conditions is vital, alongside installation and long-term expenses. Engaging with knowledgeable suppliers and maintaining an eye on market dynamics can inform better decision-making, ensuring both economic feasibility and project success. As the landscape of steel grating continues to evolve, staying informed ensures that you're not only optimizing costs but also investing in quality and durability.

Market trends and supply chain factors play a significant role in determining steel grating costs per square foot. Global demand, exchange rates, and geopolitical factors can cause price fluctuations. Keeping abreast of market trends through industry reports and news updates can provide a competitive edge when estimating project budgets. Labor and installation costs must also be factored into total expenses. While our focus is material costs, installation requires skilled labor, particularly for larger or more complex installations. Given the variability of labor rates, localized estimates should be acquired to ensure accurate budgeting. Sometimes, choosing prefabricated systems can save time and reduce installation expenses, making them worth considering depending on the project scope. When analyzing costs, consider potential suppliers’ expertise and reputation. Vendors experienced in fabricating steel grating tend to offer better support, ensuring quality materials and adherence to specifications, leading to cost effectiveness in long-term projects. Establishing relationships with reliable suppliers can lead to favorable negotiations, discounts, and assurance in quality—an often overlooked yet valuable component in managing material costs. In conclusion, understanding the cost per square foot of steel grating requires a multi-faceted approach. Consideration of material choice, size, finish, and market conditions is vital, alongside installation and long-term expenses. Engaging with knowledgeable suppliers and maintaining an eye on market dynamics can inform better decision-making, ensuring both economic feasibility and project success. As the landscape of steel grating continues to evolve, staying informed ensures that you're not only optimizing costs but also investing in quality and durability.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP