Exploring Punched Metal Sheets Versatility and Applications

Punched metal sheets are an essential component in various industries due to their versatility and wide-ranging applications. This process involves creating holes or cut-outs in sheets of metal using stamping or punching techniques. The result is a material that is not only lightweight but also possesses enhanced structural qualities, making it ideal for a multitude of uses.

One of the primary characteristics that make punched metal sheets popular is their design flexibility. The holes or patterns can be customized according to specific project requirements, allowing for both aesthetic appeal and functional efficiency. This makes them a preferred choice for architects and designers who wish to incorporate intricate designs into buildings, facades, and interior spaces. The open areas can also contribute to natural ventilation and light diffusion, making punched sheets an excellent option for environmentally conscious design.

In the manufacturing sector, punched metal sheets are extensively used for filtering applications. The precision of the punched holes allows for specific airflow, liquids, or sound to pass through while blocking unwanted debris. This property is particularly valuable in industries such as automotive, aerospace, and HVAC, where filters play a critical role in performance and safety. Additionally, the sheets are often employed in creating heat exchangers, enhancing energy efficiency by maximizing surface area for thermal transfer.

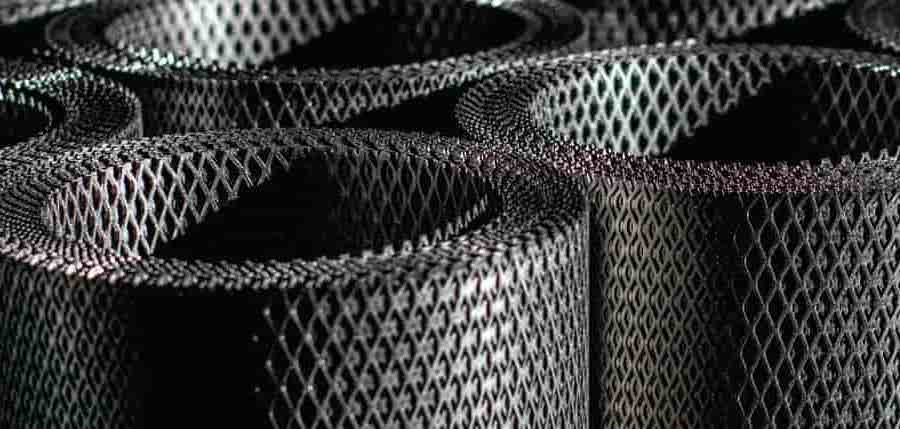

punched metal sheets

Moreover, punched metal sheets are increasingly favored in the production of decorative elements. They can be found in various consumer products, from furniture to lighting fixtures, where aesthetics meet functionality. The ability to create unique patterns can transform an ordinary object into a statement piece. Retail displays often utilize punched sheets for their eye-catching designs while ensuring product visibility and accessibility.

Another significant advantage of punched metal sheets is their durability and strength. The perforation process does not compromise the structural integrity of the metal; instead, it can potentially increase the material's strength-to-weight ratio. This characteristic is particularly important in construction, where strength, safety, and weight considerations are paramount. The sheets can be made from various materials, including steel, aluminum, and stainless steel, further broadening their usability across different environments.

In conclusion, punched metal sheets offer a unique blend of functionality, aesthetics, and durability, making them an invaluable resource in both industrial and creative applications. As technology continues to evolve, the methods for creating and utilizing these sheets will likely advance, further enhancing their role in modern design and manufacturing. With their countless benefits, punched metal sheets are poised to remain a staple in various industries for years to come.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.