2월 . 02, 2025 04:45

Back to list

Stainless Steel Plate Material Galvanized Expanded Metal Mesh

Pierced sheet metal, also known as perforated metal, has become a quintessential component in various industries due to its versatility and durability. Drawing from years of experience in the material sciences industry, one could understand why this material remains a stalwart choice for projects requiring both function and aesthetic appeal.

An anecdote from a leading construction firm elucidates the material's effectivity — during a high-rise project, the team faced challenges with ventilation. Standard solutions proved inefficient until pierced sheet metal was implemented. Not only did it solve the airflow issue, but its aesthetic appeal also added a modern touch to the building's overall design. Economically, pierced sheet metal offers significant cost benefits. Its installation is relatively straightforward, reducing labor costs. Additionally, its durability means fewer repairs and replacements over time, which can lead to substantial long-term savings. When considering sustainability, using pierced sheet metal can contribute positively to green building certifications. Manufacturers are increasingly using recyclable materials, which means that opting for pierced metal often aligns with environmentally conscious building practices. For businesses contemplating how to integrate pierced sheet metal into their operations, consultation with experienced professionals is recommended. These experts bring a wealth of knowledge about the nuances of material selection and application, thereby ensuring that project outcomes align with both aesthetic goals and functional requirements. In conclusion, pierced sheet metal embodies the ideal blend of beauty, resilience, and functionality. Its diverse applications and performance features make it an indispensable resource in modern design and engineering. By harnessing its capabilities and maintaining a commitment to quality and sustainability, businesses and industries can capitalize on the numerous benefits that pierced sheet metal offers.

An anecdote from a leading construction firm elucidates the material's effectivity — during a high-rise project, the team faced challenges with ventilation. Standard solutions proved inefficient until pierced sheet metal was implemented. Not only did it solve the airflow issue, but its aesthetic appeal also added a modern touch to the building's overall design. Economically, pierced sheet metal offers significant cost benefits. Its installation is relatively straightforward, reducing labor costs. Additionally, its durability means fewer repairs and replacements over time, which can lead to substantial long-term savings. When considering sustainability, using pierced sheet metal can contribute positively to green building certifications. Manufacturers are increasingly using recyclable materials, which means that opting for pierced metal often aligns with environmentally conscious building practices. For businesses contemplating how to integrate pierced sheet metal into their operations, consultation with experienced professionals is recommended. These experts bring a wealth of knowledge about the nuances of material selection and application, thereby ensuring that project outcomes align with both aesthetic goals and functional requirements. In conclusion, pierced sheet metal embodies the ideal blend of beauty, resilience, and functionality. Its diverse applications and performance features make it an indispensable resource in modern design and engineering. By harnessing its capabilities and maintaining a commitment to quality and sustainability, businesses and industries can capitalize on the numerous benefits that pierced sheet metal offers.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

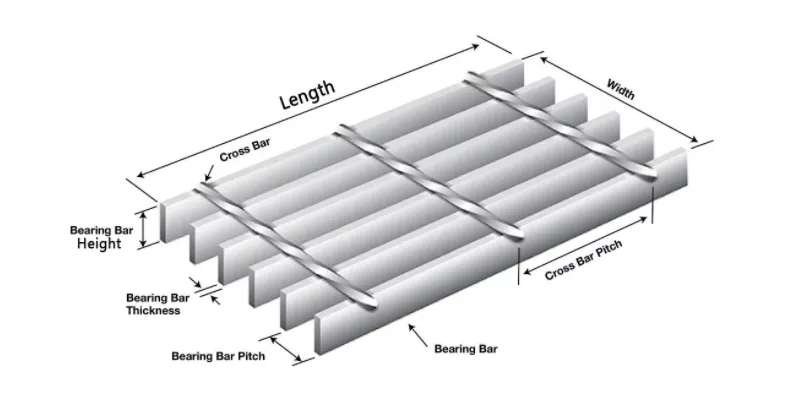

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP