Understanding the Price of Perforated Sheets per Square Foot

In various industries, perforated sheets have gained immense popularity due to their versatility, functionality, and aesthetic appeal. These sheets, characterized by a series of holes punched or drilled into them, serve several purposes, including air and liquid flow regulation, lightweight structural support, and visual enhancement. With the increasing demand for these materials, understanding the pricing of perforated sheets per square foot becomes crucial for both consumers and manufacturers.

What are Perforated Sheets?

Perforated sheets are made from various metals such as steel, aluminum, and copper, as well as from plastic and other composite materials. The perforations can vary significantly in size, shape, and spacing, depending on the intended application. Common uses for perforated sheets include applications in architectural design, industrial filtering systems, and acoustical panels, among many others.

Factors Influencing the Price of Perforated Sheets

The price of perforated sheets per square foot can fluctuate based on several factors, including

1. Material Type The choice of material has a significant influence on price. For example, stainless steel perforated sheets tend to be more expensive due to their corrosion resistance and longevity when compared to plastic or aluminum options. On average, aluminum sheets can cost around $1.50 to $3.00 per square foot, whereas stainless steel could range from $3.00 to $6.00 or more per square foot depending on thickness and grade.

2. Sheet Thickness The thickness of the sheet directly impacts the cost. Thicker sheets usually provide greater strength and durability but also come with a higher price tag. While thinner sheets may be adequate for lighter applications, they are often less costly.

3. Hole Size and Pattern The complexity of the perforation pattern is another critical factor. Custom designs with intricate hole patterns could lead to increased manufacturing costs, thereby raising the price per square foot. Standard patterns are typically less expensive due to economies of scale in production.

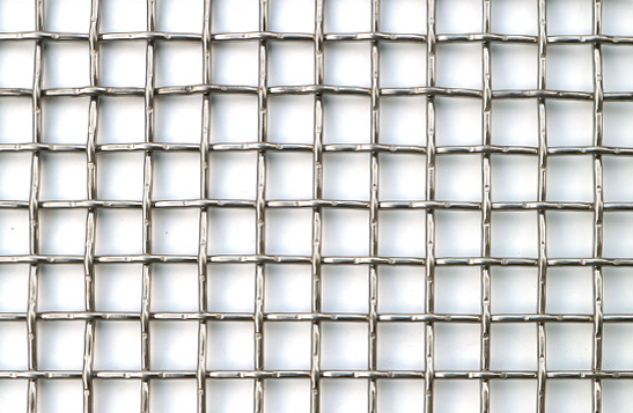

perforated sheet price per sq ft

4. Quantity Ordered Bulk purchases often result in lower prices per square foot due to reduced production and shipping costs. Many manufacturers offer tiered pricing structures that reward higher volume purchases with discounts.

5. Market Demand Market conditions, including demand and supply, can also influence pricing. In times of high demand, prices may rise, while a surplus of materials can lead to lower prices.

6. Supplier and Location Different suppliers might have varying pricing structures based on their own operational costs, location, and distribution networks. Shipping costs can also affect the final price, particularly for larger orders or longer distances.

Applications and Trends

Perforated sheets are utilized across numerous sectors, including construction, automotive, and electronics. Their ability to provide strength while minimizing weight makes them an ideal choice for applications such as façade panels, grilles, and safety screens. Furthermore, the ongoing trend of eco-friendliness and sustainability in construction and manufacturing is pushing companies to explore materials that not only enhance design but also improve energy efficiency—an area where perforated sheets excel due to their airflow capabilities.

Conclusion

When considering the price of perforated sheets per square foot, it’s essential to account for the many influencing factors, including material, thickness, and custom features. For those looking to incorporate perforated sheets into their projects, being aware of these variables can help in budget planning and optimizing material selection. As industries continue to innovate, the role of perforated sheets is likely to expand, making them an important element in modern manufacturing and design. Understanding their pricing is crucial for making informed purchasing decisions and effectively leveraging their unique benefits in various applications.

In summary, while prices may vary widely based on individual project requirements and market conditions, perforated sheets remain a cost-effective and versatile option for a wide array of applications. By taking the time to understand the factors affecting pricing, consumers can ensure they are making the best possible choice for their needs.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.