Understanding Perforated Metal Plates Versatility and Applications

Perforated metal plates are an essential component in various industries, owing to their unique properties and versatility. These plates are characterized by their uniform holes created through a perforating process, allowing for a wide range of applications from construction to manufacturing. This article explores what perforated metal plates are, their manufacturing process, typical uses, and benefits.

What Are Perforated Metal Plates?

Perforated metal plates are sheets of metal that have been punctured with a series of holes in specific patterns. These holes can vary in size and shape, ranging from round and square to more intricate designs. The metal used can be steel, aluminum, brass, or even plastic, making perforated plates suitable for numerous applications. The holes can be sized to control airflow, light, and sound, while the remaining metal structure provides strength and integrity.

Manufacturing Process

The manufacturing of perforated metal plates involves several steps. Initially, a flat sheet of metal is chosen based on the desired properties and intended use. The sheets are then placed in a perforating machine, which uses a punch and die mechanism to create holes in the specified pattern. The size, spacing, and configuration of the holes can be customized to meet specific requirements.

There are several techniques employed in the perforation process, including

1. Mechanical Punching This method uses mechanical presses to punch out holes, suitable for high-volume production. 2. Laser Cutting For more intricate patterns and designs, laser cutting can create precision holes with minimal material waste.

3. Water Jet Cutting This technique utilizes high-pressure water jets to achieve clean cuts in thicker materials, allowing for both perforation and intricate design work.

Whether produced via punching, laser cutting, or water jet cutting, the result is a high-strength, lightweight metal plate that can be easily manipulated and integrated into various applications.

Applications of Perforated Metal Plates

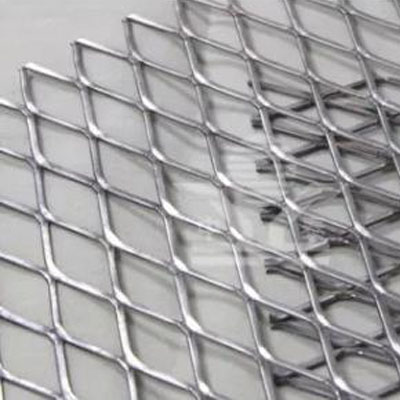

perforated metal plate

Perforated metal plates are used in a multitude of sectors due to their adaptability

. Some common applications include1. Architecture and Design Designers often use perforated metal plates in facades, sunshades, and columns. These plates can add aesthetic appeal while allowing for ventilation and light filtration.

2. Industrial Uses In factories, perforated plates can be used as filters, screens, and guards. They serve as effective barriers against debris while allowing air or liquid to flow through.

3. Acoustic Applications Perforated metal is used in sound dampening panels in auditoriums and recording studios, as the holes can help to absorb sound waves and manage acoustics.

4. Safety and Security These plates can be integrated into security screens or barriers that provide visibility while maintaining safety, often utilized in public transport systems for both durability and style.

5. Grills and Walkways Perforated metal is commonly found in grills and walkways, offering slip resistance and drainage while allowing light and air to pass through.

Benefits of Using Perforated Metal Plates

The benefits of using perforated metal plates are substantial. They provide strength and durability while being lightweight and flexible. Their ability to allow for airflow and light makes them ideal for various environmental conditions. In addition, the versatility in design means they can suit diverse aesthetic preferences, making them a favorite among architects and designers alike.

Furthermore, perforated plates can also be more cost-effective than solid sheets, particularly in applications that require large surface areas with less material. The manufacturing process allows for efficiency and customization, which can meet or exceed specific requirements for any project.

Conclusion

In conclusion, perforated metal plates are a fantastic example of practical engineering, offering both functional benefits and aesthetic appeal. As technology advances, the capabilities and applications of these plates continue to expand, solidifying their importance across multiple industries. Whether used in construction, manufacturing, or design, perforated metal plates are an indispensable resource that meets the demands of modern applications.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.